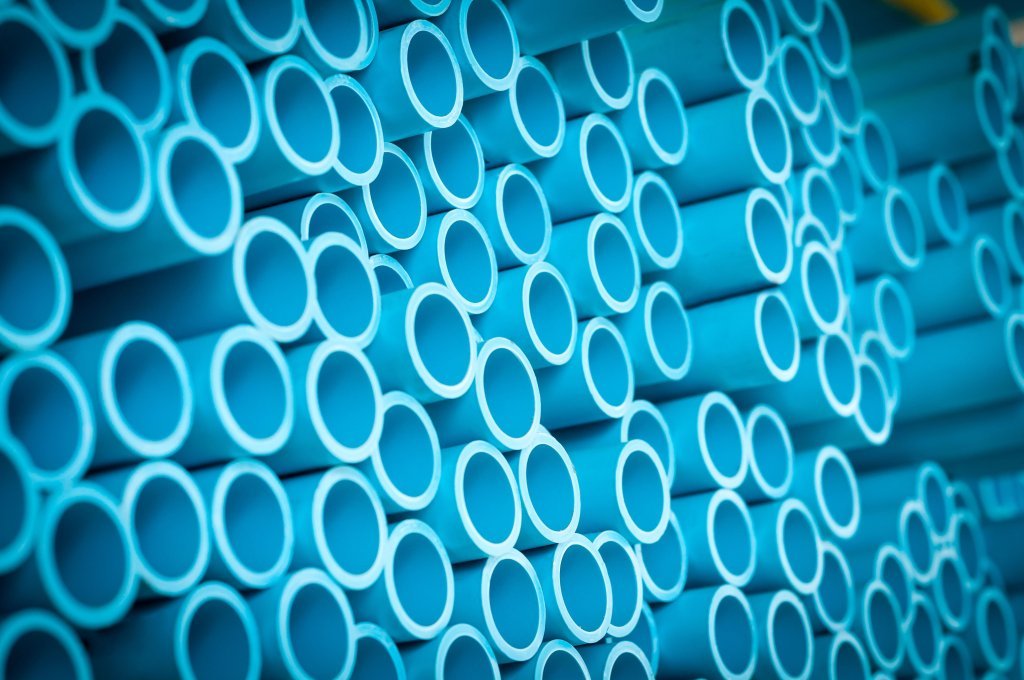

Professional Customized Plastic Pipe Machine

Professional customized plastic pipe machine, support various types of pipe models.

Plastic Pipe Machine Recommendation

PVC Extruder Can Be Vustomized Products

$8,000.00

Key Components of a Plastic Pipe Extrusion Machine

- Extruder: The heart of the machine where plastic raw materials are melted and homogenized. The extruder typically consists of a hopper, barrel, screw, and heating elements.

- Die: The die shapes the molten plastic into the desired pipe profile. It determines the diameter and wall thickness of the pipe.

- Cooling System: After extrusion, the hot pipe is passed through cooling tanks (usually water-based) to solidify and stabilize its shape.

- Haul-Off Unit: This component pulls the extruded pipe through the cooling process at a consistent speed to ensure uniformity.

- Cutting Unit: The continuous pipe is cut into specific lengths as required. The cutting unit ensures precision and consistency in pipe length.

- Control System: Advanced control systems (often PLC-based) manage the entire extrusion process, including temperature, pressure, and speed, ensuring high efficiency and product quality.

- Efficiency: Capable of producing long, continuous lengths of pipe, leading to high production rates and reduced labor costs.

- Consistency: Ensures uniform dimensions and quality, critical for applications requiring precise specifications.

- Versatility: Suitable for producing pipes of various diameters and materials, making it adaptable for different applications.

- Cost-Effective: Minimizes material waste and reduces production costs, offering a cost-effective solution for pipe manufacturing.

Benefits of Using a Plastic Pipe Extrusion Machine

Plastic Pipe Machine Applications

Construction

Water supply, drainage, and sewage systems.

Agriculture

Irrigation and water management systems.

Industrial

Chemical processing, ventilation, and ducting.

Household

Plumbing, gas supply, and electrical conduits.

JianTai’s Solutions for Plastic Pipe Extrusion Machines

JianTai offers comprehensive solutions for plastic pipe extrusion machines, designed to meet the diverse needs of the modern plastic manufacturing industry. Our advanced extrusion technology ensures high precision and efficiency, producing pipes with exceptional durability and consistency. The machines are equipped with state-of-the-art PLC control systems for easy operation and precise control, allowing for seamless adjustments and optimal performance.

Our plastic pipe extrusion machines are versatile, capable of processing various materials such as PVC, HDPE, and PP, making them suitable for a wide range of applications, from construction to agriculture. With robust construction and high-quality components, JianTai’s machines guarantee long-lasting performance and minimal maintenance.

At JianTai, we are committed to sustainability and innovation. Our machines are designed to be energy-efficient, reducing operational costs and environmental impact. Whether you need a standard machine or a customized solution, JianTai provides expert support and tailored solutions to help you achieve your production goals efficiently and sustainably.

Choose JianTai for reliable, efficient, and eco-friendly plastic pipe extrusion solutions. Visit our website or contact us to learn more about our products and how we can support your business needs.