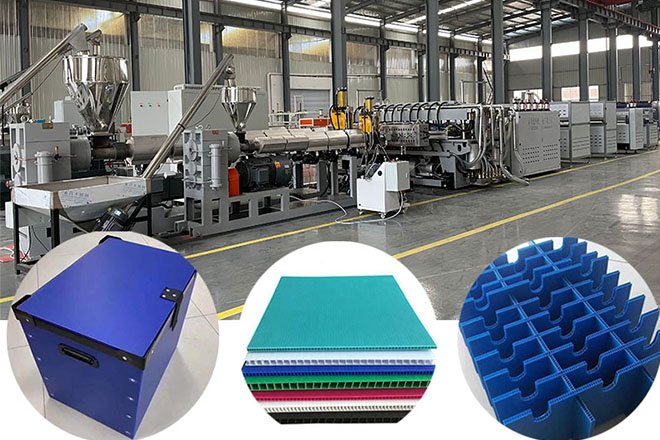

Professional Customized Plastic Sheet Machines

What Is A Plastic Sheet Machine?

A plastic sheet machine, also known as a plastic sheet extrusion machine, is specialized equipment used to produce plastic sheets from various types of plastic materials. The machine operates by melting plastic granules or pellets and then forming them into continuous sheets of uniform thickness and width. Here are the key components and functions of a plastic sheet machine:

Extruder

The primary component where plastic raw materials (such as PP, PE, PVC, or PET) are fed, melted, and homogenized. It typically includes a screw and barrel mechanism that applies heat and pressure to the plastic.

Die Head

The molten plastic is forced through the die head, which shapes it into a flat, continuous sheet. The die design determines the sheet’s width and thickness.

Calendering Unit

This unit consists of a series of rollers that further shape, smooth, and ensure the uniform thickness of the plastic sheet. The rollers can also impart surface textures if needed.

Cooling System

The sheet is cooled using a series of cooling rolls or air cooling systems to solidify the plastic and set its shape.

Haul-off Unit

Pulls the sheet through the line at a consistent speed to maintain uniform thickness and surface quality.

Cutting Unit

Cuts the continuous sheet into specified lengths or rolls it into large coils for easy handling and transportation.

Winding Unit

Collects the finished sheets, either stacking them in sheets or rolling them into coils for packaging and distribution.

Plastic sheet machines are used in various industries to produce sheets for applications such as packaging, automotive, construction, and signage. They offer high efficiency, precision, and the ability to produce sheets with various properties, including different thicknesses, textures, and colors.

Advantages of JianTai Customized Plastic Sheet Machines

JianTai’s customized plastic sheet machines offer numerous advantages, leveraging the company’s extensive experience and expertise.

19 Years of Experience

With 19 years of industry experience, JianTai has a deep understanding of plastic sheet extrusion technology. This extensive knowledge ensures high-quality, reliable machines that meet industry standards and customer expectations.

Precision Customization

JianTai specializes in precision customization of extrusion machines and molds. They can tailor each machine to exact specifications based on customer data, ensuring optimal performance and efficiency for specific production needs.

Advanced Technology

Utilizing the latest advancements in extrusion technology, JianTai machines offer superior performance, durability, and efficiency. This ensures that customers receive the best possible equipment for their production requirements.

High-Quality Materials

JianTai uses high-quality materials in the construction of their machines, ensuring long-lasting performance and reduced maintenance needs. This commitment to quality results in robust and reliable machinery.

Industry-Specific Solutions

With a wide range of customization options, JianTai can cater to various industries, including packaging, automotive, construction, and signage. Their machines are designed to meet the specific needs and challenges of different applications.

Cost-Effective Solutions

By offering tailored solutions, JianTai helps customers achieve cost-effective production processes. Customization ensures that each machine is perfectly suited to the customer’s requirements, minimizing waste and maximizing productivity.

Welcome To Find Us Customized Plastic Sheet Machine

| Plastic Extruder | √ |

| Plastic Extruder Abrasives | Customization by data |

| Plastic Cooling Unit | √ |

| Plastic Traction Machine | √ |

| Plastic Cutting Machine | √ |

What equipment is available in our plastic sheet machines?