What is a Plastic Extruder?

Introduction to Plastic Extrusion

Plastic extrusion is a key process in the manufacturing industry. It involves shaping plastic materials by melting them and forcing them through a die to create various products. The machine responsible for this process is called a plastic extruder. It plays a vital role in creating everyday items like pipes, sheets, and films.

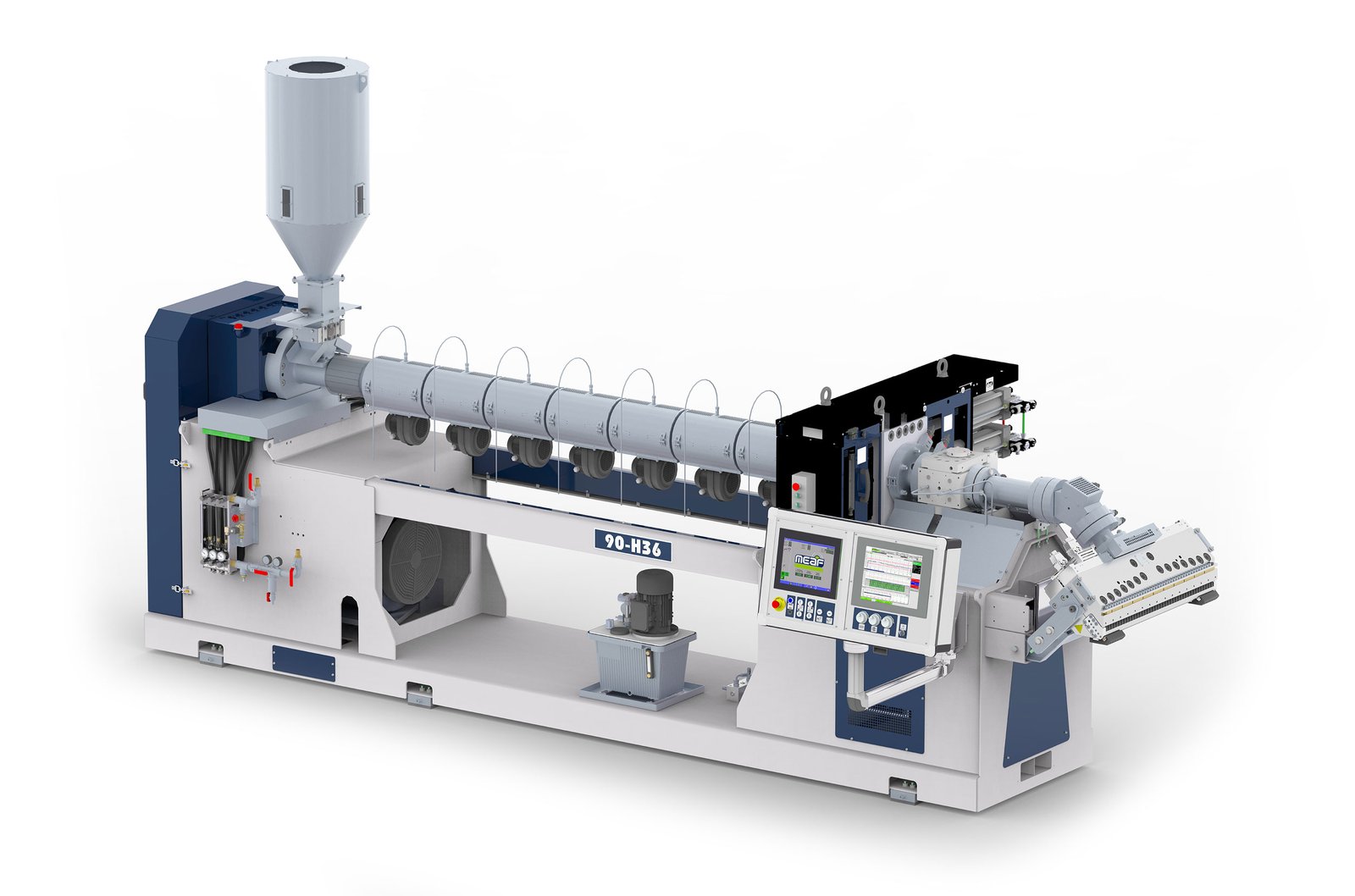

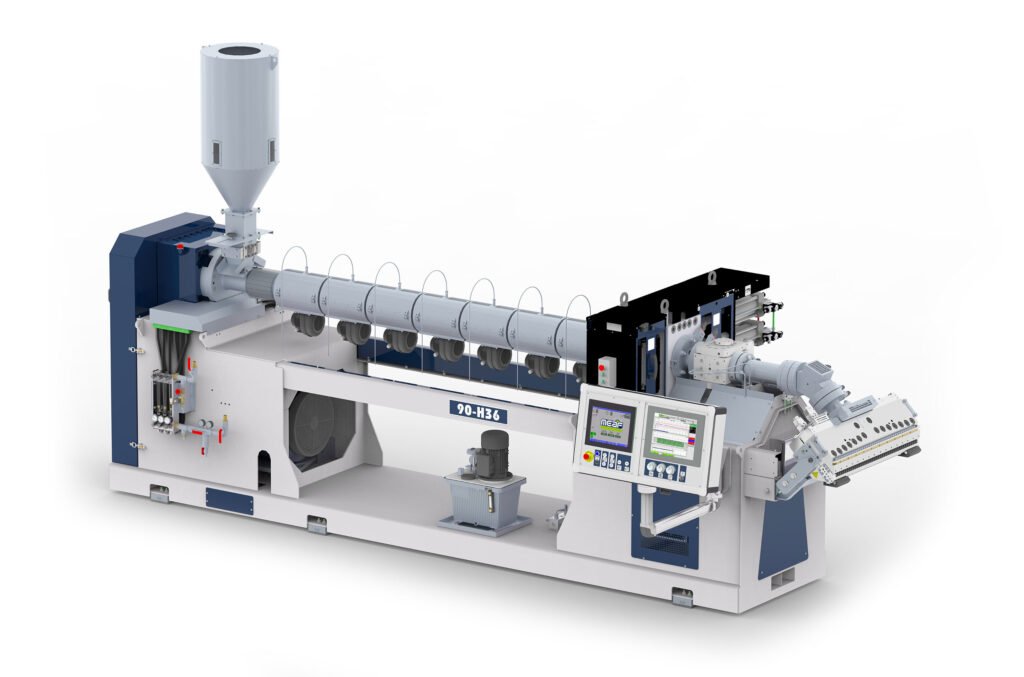

The Basic Components of a Plastic Extruder

Plastic extruders are composed of several main parts. The hopper, where raw plastic material is fed into the machine, is the starting point. From there, the plastic moves to the barrel, where it is heated and mixed. Next, the screw inside the barrel pushes the molten plastic towards the die. Finally, the die shapes the plastic into the desired form.

How Does a Plastic Extruder Work?

The process starts when raw plastic, usually in the form of pellets or granules, is poured into the hopper. The plastic is then moved into the barrel, where heaters gradually melt it. As the plastic melts, the rotating screw moves it toward the die. The pressure and heat continue to build, ensuring the plastic is in a perfect state to be shaped. When the molten plastic reaches the die, it is forced through, taking on the shape of the die’s opening. This continuous process allows for the production of long shapes like pipes or sheets.

Types of Plastic Extruders

Single-Screw Extruders

The most common type of plastic extruder is the single-screw extruder. As the name suggests, it has one screw inside the barrel. This type is widely used due to its simplicity and efficiency. Single-screw extruders are perfect for straightforward tasks like making pipes or sheets.

Twin-Screw Extruders

Twin-screw extruders have two screws that rotate together inside the barrel. These are more complex than single-screw extruders and are used for tasks that require more mixing or handling of difficult materials. They are often used in creating complex plastic products that need precise control and uniformity.

Extrusion Blow Molding Machines

Extrusion blow molding is a special type of plastic extrusion that creates hollow objects like bottles or containers. In this process, the extruded plastic is inflated into a mold, forming a hollow part. These machines are vital in producing plastic containers used in packaging.

Applications of Plastic Extruders

Everyday Products

Plastic extruders are responsible for creating many items we use daily. For instance, the plastic pipes used in plumbing are made using extrusion. Similarly, plastic sheets used in packaging or construction are produced by extruders. Without these machines, many of the products we rely on would not exist.

Industrial Uses

Beyond everyday products, plastic extruders play a significant role in industrial applications. For example, they are used to create insulation for electrical wires, making them essential in the electronics industry. Additionally, extruders are used in automotive manufacturing to produce various components.

Custom and Specialized Products

Some industries require custom or specialized plastic products. Plastic extruders can be adapted to create unique shapes or materials, catering to specific needs. Whether it’s a complex medical device or a specialized part for a machine, plastic extruders make it possible.

The Advantages of Using Plastic Extruders

Efficiency and Speed

Plastic extruders are incredibly efficient machines. They can produce large quantities of products in a short amount of time. This efficiency makes them ideal for industries that need to produce a lot of material quickly. Additionally, the continuous process of extrusion means there is less waste compared to other manufacturing methods.

Versatility in Materials and Products

One of the main advantages of plastic extruders is their versatility. They can handle a wide range of plastic materials, from soft PVC to rigid polypropylene. This flexibility allows manufacturers to create diverse products using the same machine, which is cost-effective and convenient.

Consistency in Quality

Plastic extruders provide consistent results. Because the process is controlled and automated, the products made are uniform in shape and quality. This consistency is crucial in industries where precision is important, like in medical or automotive manufacturing.

Challenges in Plastic Extrusion

Material Selection

Choosing the right material is essential in plastic extrusion. Different plastics have different melting points, strengths, and flexibility. Selecting the wrong material can result in poor-quality products or even damage to the extruder. Therefore, understanding material properties is crucial for success in extrusion.

Maintenance and Upkeep

Plastic extruders are complex machines that require regular maintenance. The screws, barrels, and dies must be cleaned and inspected frequently to ensure the machine runs smoothly. Any wear and tear can affect the quality of the products being made, so proper upkeep is necessary.

Environmental Concerns

Plastic production, including extrusion, raises environmental concerns. The process involves using raw plastic materials, which are often derived from non-renewable resources. Additionally, plastic waste is a significant environmental issue. However, advancements in recycling technology and biodegradable plastics are helping to mitigate these concerns.

Innovations in Plastic Extrusion

Advances in Material Technology

Recent developments in material technology have expanded the possibilities of plastic extrusion. For example, biodegradable plastics can now be used in extruders, reducing the environmental impact. Additionally, new composite materials that combine plastic with other substances are being developed, offering enhanced properties like increased strength or flexibility.

Energy Efficiency Improvements

Modern plastic extruders are becoming more energy-efficient. By optimizing the heating and cooling systems, manufacturers can reduce energy consumption, lowering costs and environmental impact. Energy-efficient extruders are becoming more common, reflecting the industry’s shift towards sustainability.

Automation and Smart Extruders

Automation is another area where plastic extrusion is evolving. Smart extruders equipped with sensors and AI can monitor the extrusion process in real-time, making adjustments to ensure optimal performance. These innovations lead to higher productivity and reduced waste, making the extrusion process more efficient.

Conclusion: The Importance of Plastic Extruders

Plastic extruders are indispensable in modern manufacturing. They provide the means to create a vast array of products that are essential in our daily lives and various industries. From simple pipes to complex medical devices, the versatility and efficiency of plastic extruders make them a cornerstone of the manufacturing world. As technology advances, plastic extrusion will continue to evolve, offering new possibilities and solutions for the challenges ahead.

In understanding how plastic extruders work and their significance, it becomes clear that these machines are not just tools but the backbone of many industries.