A PVC extruder is a machine that makes long, continuous shapes out of PVC plastic. It works by melting the plastic and pushing it through a mold, called a die, to create items like pipes, sheets, or profiles. Here’s how it works step-by-step:

How a PVC Extruder Works

- Feeding the PVC:First, small pieces of PVC, called pellets, are put into the extruder. These pellets are fed into a long, heated tube called a barrel.

- Melting the PVC:Inside the barrel, there is a screw that turns and pushes the PVC pellets forward. As the pellets move, the heat melts them, turning them into a thick, gooey liquid.

- Shaping the PVC:At the end of the barrel, the machine pushes the melted PVC through a die. The die is like a mold that shapes the PVC into the desired form, such as a pipe or a sheet.

- Cooling the PVC:Once the PVC comes out of the die, it is still hot and soft. The machine then quickly cools it down, usually with water or air, to harden it into its final shape.

- Cutting the PVC:The final step is cutting the PVC into the desired length. For example, if you are making PVC pipes, the extruder will cut them into the correct size.

Why Use a PVC Extruder?

- Efficiency:PVC extruders can produce a large amount of material quickly, making them very efficient for manufacturing.

- Versatility:They can create many different shapes and sizes by changing the die at the end of the extruder.

- Consistency:The process ensures that the final products are uniform and consistent in quality.

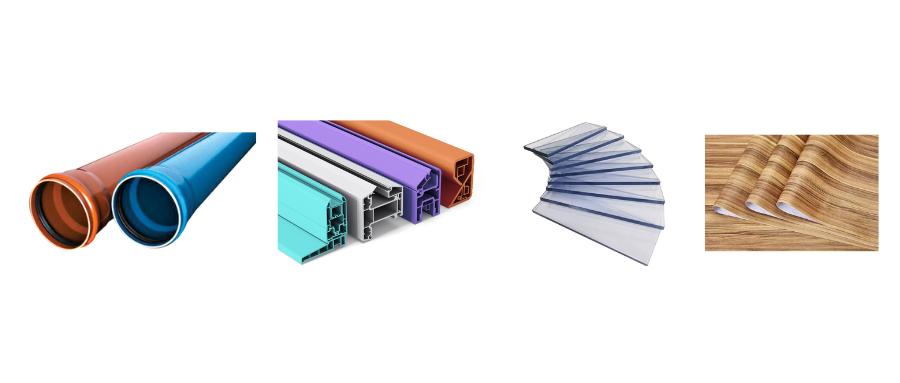

PVC Extruder Applications

- PVC Pipe Production:PVC extruders are widely used to produce various types of pipes, such as drainage pipes, water supply pipes, and cable conduits. Manufacturers select different molds and adjust extrusion parameters based on the pipe’s intended use.

- PVC Profile Production:This equipment produces building profiles like window frames, door frames, and wall panels. By changing the molds, manufacturers can create different cross-sectional profiles.

- PVC Sheet Production:Manufacturers use PVC extruders to produce PVC sheets such as foam sheets, clear sheets, and rigid sheets. These sheets are then utilized in advertising signs, building decorations, and more.

- PVC Film Production:PVC extruders also produce PVC films, which are widely used for packaging, covers, and decoration.

Technical Features and Advantages

- High Efficiency: Modern PVC extruders typically have high efficiency, allowing for the production of high-quality PVC products at high speeds with low energy consumption.

- Versatility: By changing molds and adjusting operating parameters, PVC extruders can produce various shapes and sizes of products, meeting diverse market demands.

- High Degree of Automation:Many PVC extruders are equipped with advanced automation control systems, such as PLC control. These systems allow for precise control of temperature, pressure, and speed, thereby improving production efficiency and product consistency.

Buying Tips

- Consider Production Needs:Choose the appropriate screw diameter and length-to-diameter ratio based on the specifications and output of the required products.

- Focus on Quality and After-Sales Service:Select reputable brands and reliable suppliers to ensure the quality of the machine and provide good after-sales service.

- Understand Technical Support:Choose suppliers capable of providing technical support, which can help with equipment installation, commissioning, and maintenance.

- Evaluate Cost-Effectiveness:Consider the price, performance, energy consumption, and maintenance costs of the equipment to select the most cost-effective machine.

Summary

PVC extruders are key equipment for producing PVC products, featuring high efficiency, versatility, and a high degree of automation. They are widely used in the production of pipes, profiles, sheets, and films. When purchasing, it is important to consider production needs, quality, after-sales service, and cost-effectiveness to ensure the right equipment is selected.

JianTai PVC Extruder Main Parameters

| Model | Long dia. ratio | Output (kg/h) | Screw rotate speed (r/min) | Power (kw) | Center height (mm) |

|---|---|---|---|---|---|

| JT-SJP-30-25 | 25:1 | 19.5 | 10-160 | 3/4 | 1000 |

| JT-SJP-45-20 | 20:1 | 22.5 | 10-90 | 5.5 | 1000 |

| JT-SJP-45-25 | 25:1 | 35.0 | 16-160 | 11/15 | 1000 |

| JT-SJP-50-30 | 30:1 | 70.0 | 16-160 | 18.5 | 1000 |

| JT-SJP-50-20 | 20:1 | 60.0 | 8-80 | 11 | 1000 |

| JT-SJP-55-25 | 25:1 | 120.0 | 10-160 | 22/30 | 1000 |

| JT-SJP-65-28 | 28:1 | 120.0 | 15-120 | 22/30/37 | 1000 |

| JT-SJP-65-30 | 30:1 | 120.0 | 15-120 | 22/30/37 | 1000 |

| JT-SJP-65-34 | 34:1 | 120.0 | 15-120 | 22/30/37 | 1000 |

| JT-SJP-90-22 | 22:1 | 150.0 | 10-100 | 37/45 | 1000 |

| JT-SJP-90-25 | 25:1 | 155.0 | 10-100 | 45/55 | 1000 |

| JT-SJP-120-25 | 25:1 | 250.0 | 30-90 | 75 | 1000 |

Support Alibaba International Station online trading orders.

Johan –

Very helpful plastic extruder, JianTai Plastic Machinery Company customized machinery is really good. Worth recommending!