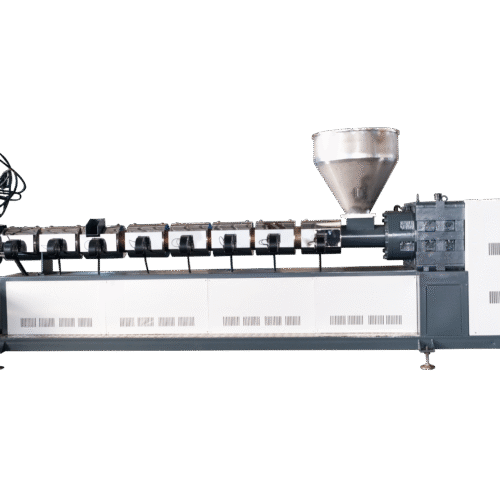

Product Introduction of PP/PE Pelletizing Line

- Overview of the Pelletizing Line

This pelletizing line is specifically designed for producing polypropylene (PP) and polyethylene (PE) pellets. It is suitable for recycling and reprocessing various types of raw materials, transforming waste plastics into high-quality recycled pellets. These pellets can be widely used in the production of plastic products. The line is stable in performance and easy to operate, making it an ideal choice for plastic processing enterprises to achieve resource recycling and cost reduction.

- Main Equipment

Extruder

– Model: JZ-65

– Function: It heats and melts the PP/PE raw materials that have been crushed and washed. Through the shearing and mixing action of the screw, the materials are uniformly plasticized and then extruded from the die head.

– Features: It features an advanced screw design for better plasticization and high output. It is equipped with a high-precision temperature control system to ensure that the materials are processed at the optimal temperature, thereby improving product quality.

Crusher

– Model: PS-400

– Function: It crushes waste PP/PE plastic products into smaller pieces in preparation for the subsequent washing and extrusion processes.

– Features: The blades are sharp, resulting in high crushing efficiency. The crushing gap can be adjusted to accommodate raw materials of different sizes.

Washing Tank

– Model: XL-800

– Function: It cleans the crushed plastic pieces, removing surface impurities and dirt to ensure the purity of the raw materials.

– Features: It employs a multi-stage washing process for good cleaning results. It is equipped with an automatic drainage system for convenient operation.

Water Ring Vacuum Pump

– Model: SH-150

– Function: It provides a vacuum environment during the extrusion process to remove moisture and gases from the materials, increasing the density and quality of the pellets.

– Features: It has a large air extraction capacity and stable vacuum level. It runs smoothly with low noise.

Die Head

– Model: MD-40

– Function: It shapes the extruded molten material into round or flat pellets through the mold.

– Features: The mold is designed reasonably for good shaping results. It is easy to replace, allowing for the production of pellets in different shapes.

Cooling Device

– Model: LQ-600

– Function: It cools the extruded pellets, solidifying them for easier cutting and packaging in the subsequent processes.

– Features: It uses a combination of water cooling and air cooling for good cooling effects. The cooling speed is adjustable to meet the needs of different production volumes.

Pellet Cutter

– Model: QL-50

– Function: It cuts the cooled pellets into uniform lengths to ensure the appearance and quality of the products.

– Features: It has high cutting accuracy and durable blades. The cutting speed is adjustable to meet the requirements of different production volumes.

Screening Device

– Model: SF-30

– Function: It screens the cut pellets, removing substandard ones to ensure product quality.

– Features: The screen mesh size is adjustable for high screening precision. The vibration frequency is adjustable for good screening results.

- Applicable Materials

– PP (Polypropylene): It has good resistance to chemical corrosion, heat resistance, and mechanical properties. It is widely used in the production of automotive parts, household appliance casings, daily necessities, and more.

– PE (Polyethylene): It is chemically stable and has good low-temperature performance. It is suitable for the production of packaging films, pipes, containers, and other products.

- Features of the Pelletizing Line

– High Efficiency and Energy Saving: The line uses advanced energy-saving technologies and optimizes the operating parameters of each piece of equipment to achieve a balance between high output and low energy consumption.

– High Degree of Automation: The entire production process, from raw material crushing to pellet packaging, is automated. This reduces manual intervention, improves production efficiency, and ensures the stability of product quality.

– Stable Quality: It is equipped with high-precision control systems that monitor and adjust parameters such as temperature, pressure, and speed in real-time during the production process. This ensures the consistency of product quality.

– Easy Operation: The human-machine interface is user-friendly. Operators can master it easily after simple training. Moreover, the maintenance and upkeep of the equipment are also very convenient, reducing the operating costs of enterprises.

- Operating Conditions

– Power Requirements: 380V/50Hz (three-phase power)

– Floor Space: Approximately 30 square meters (the exact size depends on the equipment configuration)

– Operators: Trained technical personnel are required for operation and maintenance.

- Environmental and Safety Considerations

– Environmental Protection: The line is equipped with an exhaust gas treatment device that effectively removes odors and harmful gases generated during the production process, meeting national environmental standards.

– Safety: Each piece of equipment is equipped with safety protection devices, such as emergency stop buttons and protective covers, to ensure the personal safety of operators.

- Advantages of Used Equipment

– High Cost-Effectiveness: Compared with new equipment, used equipment is more affordable, which can help enterprises save a significant amount of capital investment. It is especially suitable for small and medium-sized plastic processing enterprises.

– Ready for Immediate Use: The equipment has been strictly debugged and tested. It is stable in performance and can be put into production immediately after purchase, shortening the equipment delivery cycle.

– Reliable Quality: The equipment selected is mature products that have been tested in the market for a long time. They have a good market reputation and stable operating performance, which can meet the needs of long-term production of enterprises.

This PP/PE pelletizing line, with its efficient production capacity, stable performance, and environmentally friendly and safe design concept, will provide your plastic processing enterprise with excellent production efficiency and high-quality products. It will help your enterprise stand out in the fierce market competition and achieve sustainable development.