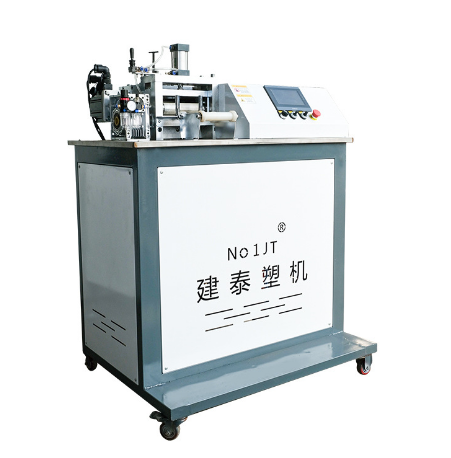

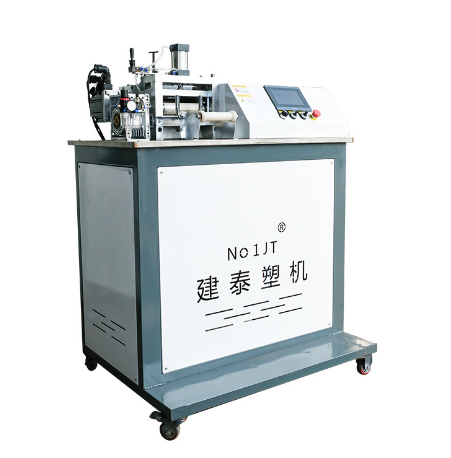

JT-SJP Series Plastic Pelletizer: A Revolution in Plastic Processing

Our JT-SJP series plastic pelletizers offer a versatile and reliable solution for converting plastics into uniform pellets. Here’s a closer look at our model range and their specifications:

| Model | L/D Ratio | Output (kg/h) | Screw Speed (rpm) | Power (kW) | Center Height (mm) |

|---|---|---|---|---|---|

| JT-SJP-45 | 28:1 | 25-30 | 10-120 | 7.5 | 650 |

| JT-SJP-65 | 28:1 | 55-70 | 10-120 | 11 | 650 |

| JT-SJP-80 | 28:1 | 100-120 | 10-120 | 18.5 | 700 |

| JT-SJP-90 | 28:1 | 120-140 | 10-120 | 22 | 730 |

| JT-SJP-100 | 28:1 | 140-170 | 10-120 | 30 | 750 |

| JT-SJP-110 | 28:1 | 180-220 | 10-120 | 37 | 750 |

| JT-SJP-120 | 28:1 | 220-260 | 10-120 | 45 | 750 |

| JT-SJP-130 | 28:1 | 270-330 | 10-120 | 55 | 800 |

| JT-SJP-140 | 28:1 | 350-420 | 10-120 | 75 | 800 |

| JT-SJP-150 | 28:1 | 450-550 | 10-120 | 90 | 800 |

| JT-SJP-160 | 28:1 | 550-650 | 10-120 | 110 | 850 |

| JT-SJP-180 | 28:1 | 800-950 | 10-120 | 150 | 900 |

Applications:

This machine is primarily used for pelletizing thermoplastics such as PC, PA, ABS, PP, PS, PE, PVC, PP-R, POM, PBT, and PET. Different screws can produce different types of plastics, and with various dies and auxiliary equipment, it can also extrude wire, film, pipes, sheets, and threads.

Why Choose JianTai’s Plastic Pelletizing Machines?

1. Exceptional Output Ranges

From the compact JT-SJP-45, capable of producing 25-30 kg/h, to the robust JT-SJP-180, delivering up to 950 kg/h, our machines cater to various production needs. Whether you are a small-scale operator or a large manufacturing unit, there’s a JianTai pelletizer suited for your requirements.

2. Optimized Screw Speed and Power Efficiency

Our machines feature adjustable screw speeds ranging from 10 to 120 rpm, allowing precise control over the pelletizing process. Combined with power ratings from 7.5 kW to 150 kW, our pelletizers provide the perfect balance between performance and energy efficiency, ensuring maximum productivity with minimal operational costs.

3. Reliable L/D Ratio for Consistent Quality

The 28:1 L/D ratio across all models ensures thorough plasticization and homogenization, resulting in uniform, high-quality pellets that meet the stringent demands of modern manufacturing processes. This consistency translates into better product quality and reduced waste in subsequent stages of production.

4. Designed for Operational Excellence

With center heights varying from 650 mm to 900 mm, our pelletizers are designed for easy integration into existing production lines. Their compact yet robust design makes them adaptable to various working environments, enhancing workflow efficiency and operational ease.

Applications Across Industries

Our plastic pelletizing machines are ideal for a range of applications:

- Plastic Manufacturing: Convert raw or recycled plastic into pellets for use in injection molding, blow molding, and extrusion.

- Recycling Plants: Efficiently process recycled plastics into high-quality pellets, ready for reuse in manufacturing.

- Chemical Engineering: Use in compounding and material blending processes to achieve precise formulations.

Commitment to Quality and Service

At JianTai, we are committed to delivering machines that embody the highest standards of engineering excellence. Each plastic pelletizer is crafted with precision and rigorously tested to ensure reliability and performance. Our customer support team is dedicated to providing comprehensive after-sales service, ensuring that your operations run smoothly.

Experience the JianTai Advantage

Choosing JianTai means investing in machines that are not only state-of-the-art but also tailored to meet the evolving needs of the plastic industry. Contact us today to learn more about how our JT-SJP series plastic pelletizing machines can enhance your production capabilities and drive your business forward.

Bill –

I am the agent of JianTai company, I am very happy that JianTai company has made the official website of the online shopping mall.