Introduction

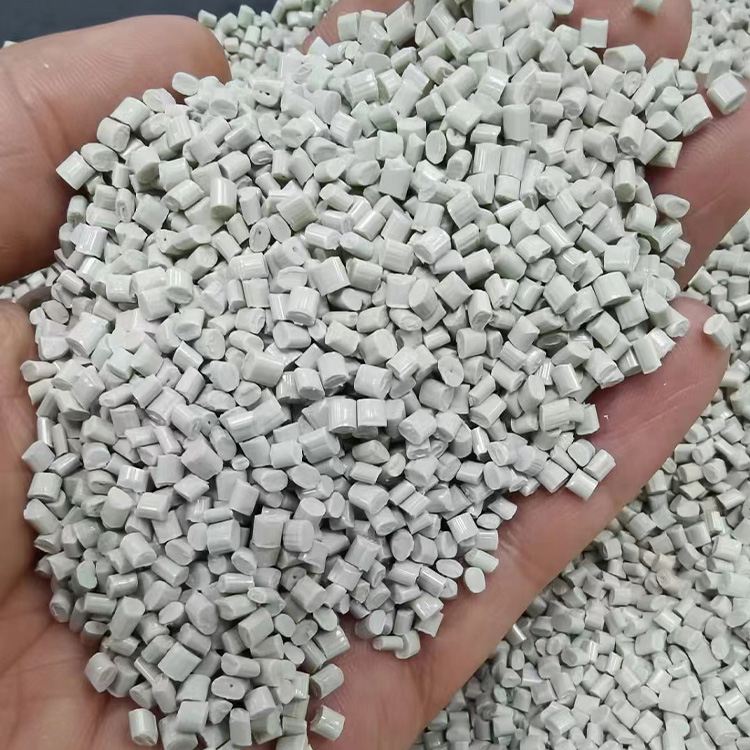

Plastic pellets are essential in modern manufacturing processes. These small granules, typically 1-5 millimeters in diameter, are crucial for creating a wide range of plastic products through injection molding. From food containers to drink bottles, plastic pellets are incredibly versatile.

Types of Polymers in Plastic Production

Several polymers commonly used in plastic production include:

- PLA (Polylactic Acid)

- PP (Polypropylene)

- ABS (Acrylonitrile Butadiene Styrene)

- PVC (Polyvinyl Chloride)

- LDPE (Low-Density Polyethylene)

- PETG (Polyethylene Terephthalate Glycol)

- TPU (Thermoplastic Polyurethane)

Each type of polymer has unique properties that determine its suitability for different applications.

Raw Materials in Plastic Pellet Formation

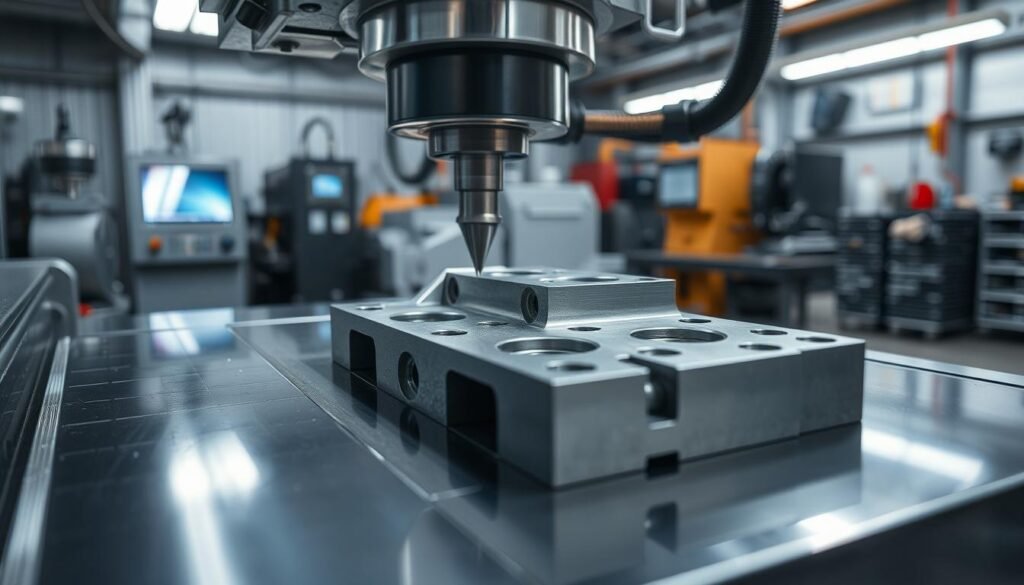

The formation of plastic pellets involves various raw materials such as oil, coal, and natural gas. Manufacturers use these raw materials to create the final pelletized product through precise forming and mechanical handling operations. Understanding the significance of these raw materials helps in appreciating the complexity and precision involved in producing high-quality plastic pellets.

To achieve the desired quality and performance of plastic pellets, it is crucial to not only focus on the raw materials but also consider specialized plastic machinery that can enhance your business product growth needs. Customized equipment can significantly improve the efficiency and output of your manufacturing processes.

Moreover, staying updated with industry trends and market insights is essential for making informed business decisions. For instance, learning how to interpret and analyze the latest plastics earnings reports can provide valuable insights that enable you to stay ahead in the market.

Understanding the Plastic Formulation Process

The plastic formulation process is a critical stage in the creation of plastic products. It involves combining various raw materials and additives to achieve desired properties and performance. This stage can be broken down into several key components:

1. Selection of Raw Materials

The base polymers such as PLA, PP, ABS, PVC, LDPE, PETG, and TPU are chosen based on the intended application of the final product.

2. Incorporation of Additives

Additives play a vital role in enhancing the functionality and durability of plastics. They are used to improve characteristics such as flexibility, strength, color, and resistance to UV light.

Key Components in Plastic Formulation

- Polymer Base: The primary material around which the formulation is built. Each polymer type brings unique properties:

- PLA (Polylactic Acid): Biodegradable and eco-friendly.

- PP (Polypropylene): Known for its durability.

- ABS (Acrylonitrile Butadiene Styrene): High impact resistance.

- PVC (Polyvinyl Chloride): Versatile with various rigid and flexible applications.

- LDPE (Low-Density Polyethylene): Excellent for flexible products like plastic bags.

- PETG (Polyethylene Terephthalate Glycol): Used for transparency and toughness.

- TPU (Thermoplastic Polyurethane): Offers elasticity and resilience.

- Additives: These are essential for tailoring the polymer’s properties to specific needs:

- Stabilizers: Protect polymers from degradation due to heat or UV exposure.

- Plasticizers: Increase flexibility and workability.

- Colorants: Provide aesthetic appeal through pigmentation.

- Flame Retardants: Enhance safety by reducing flammability.

Role of Additives in Enhancing Plastic Properties

Additives significantly impact how plastics perform under various conditions:

- Antioxidants: Prevent oxidation and degradation during processing and use. For example, antioxidants are crucial in packaging materials to extend shelf life.

- UV Stabilizers: Essential for outdoor applications where exposure to sunlight could degrade the material. This is particularly important for products like outdoor furniture or agricultural films.

- Reinforcements: Materials like glass fibers can be added to plastics to increase strength and rigidity without adding significant weight.

Practical Applications

Understanding these components allows manufacturers to create tailored solutions for diverse industries. For instance:

- In automotive parts production, additives can enhance mechanical properties while reducing weight.

- Packaging industries benefit from using stabilizers and plasticizers to ensure product safety and longevity.

To explore 10 Surprising Ways to Use Plastic Pellets You Didn’t Know About, including their impact on the environment, innovative uses in weighted blankets, shooting rests, crafts, and more, click here.

Choosing the right plastic recycling machine also involves understanding these formulation intricacies. Learn more about How to Choose a Good Plastic Recycling Machine for your business or organization.

Understanding the plastic formulation process is essential for creating high-quality

1. PLA Pellets

PLA pellets are made from renewable resources like corn starch or sugarcane, making them a type of biodegradable plastic. PLA stands for Polylactic Acid, which is a polymer that naturally breaks down over time. This makes it a more eco-friendly option compared to traditional plastics made from petroleum.

Unique Biodegradable Nature

PLA pellets have several special characteristics:

- Biodegradability: Unlike regular plastics, PLA can break down into natural substances under specific composting conditions.

- Renewable Resources: They are sourced from plants, reducing our dependence on fossil fuels.

- Low Carbon Footprint: The production of PLA generates fewer greenhouse gases compared to other types of plastics.

Common Applications Across Industries

PLA pellets are versatile and can be used in various sectors, including:

- Packaging: They are commonly used for food containers, disposable cutlery, and packaging films because they are safe to come into contact with food.

- Textiles: PLA pellets can be used to make biodegradable fabrics and fibers.

- Medical Field: They are suitable for medical implants and sutures as they can safely degrade inside the body.

- 3D Printing: PLA pellets are a popular choice for 3D printing filaments due to their ease of use and environmental advantages.

For those interested in improving efficiency and sustainability in their manufacturing processes, you can explore innovative solutions for efficient plastic pelletizing which boost efficiency, cut costs, and enhance sustainability in your manufacturing process.

Manufacturers looking to learn more about recycled plastic extrusion techniques may find valuable insights in this ultimate guide to recycled plastic extrusion machine, from working principles to innovative techniques and case studies.

Understanding the unique properties and applications of PLA pellets highlights their importance in promoting sustainable practices across various industries.

2. PP Pellets

PP pellets, or polypropylene pellets, are a crucial part of the manufacturing industry because of their exceptional properties and versatility.

Understanding PP Pellets

Polypropylene (PP) is a type of plastic that can be melted and shaped multiple times without losing its properties. It is used in many different ways because it is flexible, lightweight, and resistant to heat and chemicals.

PP pellets are small, uniform-sized pieces of polypropylene that are made by melting raw polypropylene material and then cooling it down quickly. These pellets are easy to handle and can be used in various manufacturing processes.

Key Features of PP Pellets

PP pellets have several important features that make them highly valuable:

- High Chemical Resistance: Polypropylene can withstand exposure to many different chemicals without getting damaged. This makes it suitable for making containers, pipes, and other items that will come into contact with these substances.

- Strong and Durable: PP has a high resistance to stress and cracking, which means it can last a long time even under tough conditions. This makes it ideal for products like automotive parts and reusable containers.

- Lightweight: Polypropylene is one of the lightest types of plastic available. Using PP pellets in manufacturing can help reduce the overall weight of products without sacrificing strength.

- Heat Resistant: PP has a melting point of around 160°C (320°F), which means it can withstand high temperatures without deforming or losing its properties. This makes it suitable for making items that need to be sterilized or used in hot environments.

- Good Insulator: Polypropylene does not conduct electricity well, making it useful for making electrical components that need insulation.

Common Uses of PP Pellets

Because of their unique properties, PP pellets are used in many different industries for various purposes. Some of the most common applications include:

- Automotive Parts: PP pellets are used to make components like bumpers, dashboards, and battery housings for vehicles. The durability and lightweight nature of polypropylene make it an ideal choice for these parts.

- Packaging Materials: Polypropylene’s resistance to chemicals makes it suitable for making packaging materials such as food containers, bottle caps, and bags. This ensures that the products inside remain safe and unaffected.

- Textiles: PP pellets can be transformed into fibers that are used in the production of ropes, carpets, and upholstery. The resilience and flexibility of polypropylene make it a popular choice in the textile industry.

- Medical Devices: PP’s heat resistance property is crucial in the manufacturing of medical devices that need to be sterilized, such as syringes and surgical trays.

These are just a few examples of how PP pellets are used in various industries. Their unique characteristics make them essential in modern manufacturing processes.

For more information on polypropylene properties and selection, you can refer to this selection guide on polypropylene (PP) plastic. For further insights into the

3. ABS Pellets

ABS pellets, or Acrylonitrile Butadiene Styrene pellets, are a popular choice in the plastic industry due to their unique combination of properties. ABS is a thermoplastic polymer known for its strength, rigidity, and resistance to impact and heat. These features make ABS pellets suitable for a wide range of applications, from household goods to automotive parts.

Characteristics of ABS Pellets

ABS pellets have several notable characteristics:

- Durability: ABS is highly durable and can withstand significant wear and tear. This makes it ideal for products that require longevity.

- Heat Resistance: The material’s ability to resist high temperatures ensures that it retains its shape and strength under various conditions.

- Impact Resistance: ABS can absorb impacts without cracking or breaking, which is crucial for items that need to endure physical stress.

- Ease of Processing: The thermoplastic nature of ABS allows it to be easily molded into different shapes, enhancing its versatility in manufacturing.

Common Applications

ABS pellets are widely used across various industries due to their beneficial properties:

- Automotive Industry: Components such as dashboards, wheel covers, and other interior parts often utilize ABS for its resilience and finish quality.

- Consumer Electronics: Many electronic housings, like those for computers and televisions, use ABS because of its ability to withstand heat and mechanical impact.

- Household Goods: Items such as kitchen appliances, toys, and protective gear frequently incorporate ABS pellets because they combine strength with aesthetic appeal.

The versatile nature of ABS makes it a go-to material in numerous sectors. However, with increasing concerns about sustainable materials, exploring alternatives like PVC plastic granules can lead us towards a more environmentally friendly future. Nonetheless, ABS still holds its ground as a reliable choice in the plastic industry.

It’s important to understand not only the benefits of different plastic materials but also how to address their environmental impact. For instance, exploring effective strategies for plastic pellet recycling can help minimize waste and contribute to a more sustainable manufacturing process.

4. PVC Pellets

PVC pellets, or polyvinyl chloride pellets, are a versatile and widely used form of plastic material. Known for their durability and resistance to environmental degradation, PVC pellets are a key component in many industrial and consumer products.

Characteristics of PVC Pellets

- Durability: PVC pellets offer outstanding strength, making them suitable for various applications that require long-lasting materials.

- Resistance: These pellets exhibit high resistance to chemicals, weathering, and fire, enhancing their utility in different environments.

- Flexibility: Depending on the additives used, PVC can be either rigid (RPVC) or flexible (FPVC), providing versatility in its applications.

Common Uses of PVC Pellets

PVC pellets are integral in numerous industries due to their adaptable properties:

- Construction: Often used for pipes, fittings, and siding because of their robustness and longevity.

- Healthcare: Utilized in medical devices such as IV bags and tubing due to their flexibility and safety standards.

- Automotive: Employed in manufacturing dashboards, door panels, and other interior components.

- Packaging: Used in the production of cling films and packaging materials thanks to their clear and flexible nature.

PVC’s role extends into the recycling sector as well. Innovations in plastic recycling machinery are making it possible to recycle PVC efficiently, contributing to sustainability efforts. For more insights into these advancements, you might find “Innovations in Plastic Recycling: A Look at the Latest Machinery” particularly interesting.

Modern plastic pelletizers are also revolutionizing how recycled PVC is processed. This transformation is helping turn old products into valuable raw materials for new applications. Learn more about this technology by exploring “How Modern Plastic Pelletizers are Transforming the Recycling Industry“.

PVC pellets continue to be an essential material across multiple sectors thanks to their adaptability and resilience.

5. LDPE Pellets

LDPE pellets, or Low-Density Polyethylene pellets, are widely recognized for their flexibility and durability. These pellets are produced from polymerizing ethylene at high pressure, resulting in a material that boasts a lower density compared to other polyethylene variants such as High-Density Polyethylene (HDPE).

Key Characteristics of LDPE Pellets:

- Flexibility: LDPE is known for its excellent flexibility, making it ideal for applications that require pliability without breaking.

- Transparency: It offers good clarity, which is beneficial for products that need to be see-through.

- Chemical Resistance: These pellets exhibit robust resistance to chemicals, ensuring longevity and reliability in various environments.

- Low Cost: LDPE is relatively inexpensive, providing a cost-effective solution for many manufacturing needs.

Applications of LDPE Pellets:

LDPE pellets find their place in a variety of industries due to their versatile properties:

- Packaging Materials: Widely used in the production of films, bags, and wrappings. Grocery bags and food packaging often utilize LDPE for its flexibility and strength.

- Containers and Bottles: Commonly found in squeezable bottles and other types of containers where flexibility is essential.

- Plastic Parts: Used in the manufacture of various plastic parts requiring durability and light weight.

- Agriculture: Employed in the creation of agricultural films and greenhouse coverings due to their resilience against environmental stresses.

LDPE’s ability to combine low cost with high performance makes it an attractive option across numerous sectors. Its adaptability ensures that it remains a staple material in both everyday products and specialized applications.

Understanding the distinct characteristics and applications of LDPE pellets helps manufacturers choose the right materials for specific needs, optimizing product performance and cost-efficiency.

For those looking to venture into the plastic industry, it’s crucial to partner with reputable companies that offer high-quality plastic machinery. Firms like JianTai Plastic Machinery Ltd. have established themselves as leaders in the sector, specializing in plastic recycling machines, plastic pipe machines, and plastic sheet machines. These advanced technologies are vital for efficiently working with LDPE pellets and other plastic materials.

With an unwavering commitment to research, development, and customer service, companies like JianTai Plastic Machinery Ltd. have become synonymous with reliability in the industry. By leveraging their expertise and innovative solutions, manufacturers can enhance their production capabilities and stay ahead of the competition.

6. PETG Pellets

PETG pellets are unique in the world of plastic manufacturing because of their special properties and wide range of uses. PETG, or Polyethylene Terephthalate Glycol-modified, is a type of copolyester that combines the benefits of both PET (Polyethylene Terephthalate) and glycol.

Properties of PETG Pellets

- Durability: PETG is very strong and tough, making it perfect for products that need to be long-lasting.

- Clarity: PETG is known for being extremely clear and shiny, which makes it great for applications where see-through materials are important.

- Chemical Resistance: This material can withstand many different chemicals, which means it can be used in a wide variety of industries.

- Thermoformability: PETG can easily be molded into different shapes without losing its strength.

Common Applications

PETG pellets are used in many different industries because of their great properties:

- Packaging: PETG is commonly used for food packaging because it’s clear and safe.

- Medical Devices: Its ability to resist chemicals and handle sterilization processes makes it ideal for medical purposes.

- Retail Displays: The shiny finish and see-through nature of PETG make it perfect for attractive retail displays.

- 3D Printing: PETG is becoming more popular in the 3D printing industry because it’s easy to work with and very strong.

If you’re interested in learning more about plastics, you might find this guide on how to identify different types of plastic useful. It provides valuable insights into recognizing plastics at home through recycling symbols, tests, and tips. Additionally, for a comprehensive understanding of plastic material classification, including techniques and types of plastics used in diverse applications, I recommend checking out this ultimate guide to plastic material classification in 2024.

7. Polymer Pellets

Polymer pellets are an essential component in the plastic manufacturing landscape. These small, cylindrical particles serve as the fundamental building blocks for a broad range of plastic products. Composed of various types of polymers such as polyethylene, polypropylene, and polystyrene, these pellets undergo various processes to transform into usable plastic items.

Defining Polymer Pellets

Polymer pellets are uniform pieces of thermoplastic material that can be easily melted and molded into different shapes. They typically measure between 1-5 millimeters in diameter and are produced through a process known as polymerization. During this process, monomers—small chemical molecules—are chemically bonded to form long chains called polymers.

Role in Plastic Production

The role of polymer pellets in plastic production cannot be overstated. They offer several advantages:

- Consistency: Uniform size and shape ensure consistent melting and molding characteristics, which is crucial for high-quality end products.

- Ease of Handling: Their standardized form allows for efficient transportation and storage.

- Versatility: Polymer pellets can be customized with additives to enhance properties like UV resistance, flexibility, or flame retardance.

These qualities make polymer pellets indispensable in industries ranging from automotive to consumer goods. For instance, Celanese has introduced sustainable materials that utilize polymer pellets to create advanced automotive components such as dust boots and bellows.

Their significance extends to recycling processes as well. Recycled plastics often begin their second life as polymer pellets before being remanufactured into new products. This step is crucial for sustainable practices in plastic production, as highlighted in the article From Bottles to Pellets: The Journey of Plastic Recycling, which outlines the importance of converting used plastic bottles into polymer pellets as a key step in the recycling process.

Understanding the specifics of polymer pellets enables both industry professionals and consumers to make informed decisions about material selection and sustainability practices.

8. TPU Pellets

Thermoplastic Polyurethane (TPU) pellets are a versatile type of plastic, valued for their unique combination of properties. TPU pellets are known for their elasticity, transparency, and resistance to oil, grease, and abrasion. These characteristics make them highly significant in the plastic formulation process.

Key Properties of TPU Pellets

- Elasticity: TPU pellets retain flexibility and elasticity even at low temperatures, making them ideal for applications requiring durable yet flexible materials.

- Transparency: Their inherent clarity allows for diverse usage in products where aesthetics are important.

- Chemical Resistance: They resist oils, greases, and various chemicals, ensuring longevity and robustness in harsh environments.

- Abrasion Resistance: The high abrasion resistance makes TPU an excellent choice for parts that undergo wear and tear.

Common Applications

TPU pellets find applications across multiple industries due to their adaptable properties:

- Footwear: Used extensively in shoe soles for their durability and comfort.

- Automotive: Employed in car interiors and protective covers due to their resistance to wear and chemicals.

- Medical Devices: Utilized in medical tubing and other devices because they are safe for skin contact and offer excellent performance under stress.

- Consumer Electronics: Ideal for cases and enclosures that need both protection and aesthetic appeal.

Significance in Plastic Formulation

TPU’s versatility extends its significance in the plastic formulation process. When blended with other polymers or additives, TPU can enhance the overall performance of the resulting material. This makes it a preferred choice for manufacturers seeking to improve product quality while maintaining cost efficiency.

Manufacturers looking to optimize plastic extrusion processes involving various types of polymers including TPU could benefit from exploring Plastic Sheet Extrusion Machines, which are specifically designed to meet their unique requirements. Additionally, recycling processes involving TPU can be streamlined using advanced machinery such as the HDPE Plastic Recycling Machine, featuring specialized extruders and pelletizers.

Understanding these facets of TPU pellets aids manufacturers in selecting appropriate materials tailored to specific applications, ensuring both functionality and sustainability.

How to Tell the Difference Between Plastic Pellets and Granules

Understanding the key characteristics that distinguish plastic pellets from plastic granules can enhance your material selection process. This section delves into the primary differences between these two forms.

Size and Shape

- Plastic Pellets: Typically range between 1-5 millimeters in diameter. Their shape is usually spherical or cylindrical, making them easy to handle manually.

- Plastic Granules: These are generally finer particles compared to pellets. They result from the progressive enlargement of primary particles, often leading to irregular shapes.

Production Process

- Pellets: Created through a precise forming and mechanical handling operation. This process ensures uniformity in shape and size.

- Granules: Formed during recycling processes where larger plastic pieces are ground down. This results in a more varied size distribution.

Applications

- Plastic Pellets: Commonly used in injection molding processes to form various plastic parts such as food containers and drink bottles.

- Plastic Granules: Often used in machines designed for processing recycled plastics.

Material Consistency

- Pellets: Offer consistent quality due to their controlled manufacturing process, which makes them ideal for high-quality end products.

- Granules: May exhibit variability in quality, especially when sourced from recycled materials.

Key Considerations

When selecting between pellets and granules, consider the following:

- End Use Requirements: High-end applications may benefit more from the consistency of plastic pellets.

- Recycling Goals: If sustainability is a priority, granules derived from recycled materials could be advantageous.

- Cost Factors: Granules may often be more cost-effective, particularly for large-scale production runs.

For those involved in selecting machinery for pelletizing processes, exploring efficient plastic extruders or customized pelletizing machines can enhance productivity while ensuring material quality.

Knowing these distinguishing factors helps streamline your decision-making process, ensuring optimal results tailored to your specific needs.

Examining the Environmental Impact of Plastic Pellets

The environmental impact of plastic pellets is a growing concern, especially regarding their improper handling or disposal. Significant risks emerge when plastic pellets enter the marine environment, leading to pollution that threatens aquatic life.

Potential Environmental Risks

- Marine Pollution: Plastic pellets can unintentionally enter the environment during manufacturing and transportation. These small particles often end up in rivers and oceans, contributing to the larger problem of marine pollution.

- Ingestion by Marine Life: Marine organisms, such as fish and birds, may confuse plastic pellets for food. Eating these materials that do not break down naturally can cause physical harm or death, disturbing marine ecosystems.

- Chemical Contaminants: Plastic pellets can soak up harmful chemicals from their surroundings. When consumed by marine life, these pollutants can move up the food chain, creating health hazards for both animals and humans.

Proper Handling and Disposal

To reduce these environmental impacts, it is important to follow proper handling and disposal methods:

- Implement strict protocols during manufacturing and transportation to avoid accidental spills.

- Use containment measures like barriers and filters in facilities near bodies of water.

- Encourage recycling efforts to decrease the amount of plastic waste going into the environment.

For more information on sustainable practices in plastics handling, you can read The Ultimate Guide to Plastics: From PVC to Polycarbonate, which explores the world of plastics: types, properties, uses, and environmental impact. This comprehensive resource will provide valuable insights into understanding the broader context of plastic pellet pollution.

Additionally, if you’re interested in Plastic Recycling Machines: A Step-by-Step Guide for Beginners, this detailed guide covers the types and processes involved in plastic recycling. It also highlights why plastic recycling is vital for the environment, offering practical solutions to tackle the issue.

Understanding the environmental impact of plastic pellets is crucial for developing effective strategies to protect our marine ecosystems. By prioritizing responsible management practices, such as those outlined in these resources, it is possible to reduce pollution and safeguard aquatic life.

Conclusion

Understanding the various types of plastic pellets is crucial for both industry professionals and consumers. Each type, from PLA pellets to TPU pellets, has unique properties and applications that make them suitable for different manufacturing processes. Recognizing these differences can lead to more informed decisions in product design and material selection.

Prioritizing sustainable practices in the use and management of plastic materials is equally important. With growing concerns about environmental pollution, especially marine pollution, it’s vital to adopt innovative pelletizing technology that transforms plastic waste into high-quality recycled pellets. This not only supports a circular economy but also significantly reduces environmental pollution associated with plastic production.

By embracing such innovative solutions and staying informed about sustainable practices, we can contribute to a greener future while leveraging the versatility and functionality of plastic pellets.

FAQs (Frequently Asked Questions)

What are plastic pellets and why are they significant in manufacturing processes?

Plastic pellets are small granules of raw plastic material that serve as the foundation for various manufacturing processes. They are significant because they can be melted and molded into different shapes, making them essential for the production of a wide range of plastic products.

What are the different types of polymers commonly used in plastic production?

Common types of polymers used in plastic production include polyethylene, polypropylene, polystyrene, polyvinyl chloride (PVC), and polyethylene terephthalate (PET). Each type of polymer has distinct properties that make it suitable for specific applications.

What is the role of additives in the plastic formulation process?

Additives play a crucial role in enhancing the properties and performance of plastic materials. They can improve characteristics such as strength, durability, flame resistance, and color, allowing manufacturers to customize plastics for different uses.

What are PLA pellets and what makes them unique?

PLA pellets are a type of biodegradable plastic made from renewable resources such as corn starch or sugarcane. Their unique biodegradable nature makes them an environmentally friendly alternative to traditional plastics. PLA pellets are commonly used in packaging, food service products, and medical implants.

What are the notable properties of PP pellets?

PP pellets, also known as polypropylene pellets, have excellent chemical resistance, high melting point, and good fatigue resistance. These properties make them suitable for a wide range of applications including packaging, textiles, automotive components, and medical devices.

What are the common uses of PVC pellets?

PVC pellets are widely used in the construction industry for pipes, fittings, window profiles, and vinyl siding. They are also used in healthcare applications such as medical tubing and blood bags due to their flexibility and durability.

How can one differentiate between plastic pellets and granules?

The main distinguishing factor between plastic pellets and granules is their shape. Pellets are typically cylindrical or oval-shaped, while granules are irregularly shaped. Additionally, pellets are more uniform in size and density compared to granules.

What potential environmental risks are associated with the improper handling or disposal of plastic pellets?

Improper handling or disposal of plastic pellets can lead to pollution of marine environments. When these pellets enter waterways, they can be mistaken for food by marine animals, leading to ingestion and potential harm to wildlife.

Why is it important to understand different types of plastic pellets?

Understanding different types of plastic pellets is important for industry professionals as it allows them to select the most suitable materials for their specific applications. For consumers, this knowledge empowers them to make informed choices about sustainable practices in using and managing plastic materials.