Introduction

PVC plastic granules are small pellets made from Polyvinyl Chloride (PVC), a versatile and widely used plastic. These granules play a pivotal role in the manufacturing industry, serving as the raw material for a diverse range of products. From footwear and automotive parts to medical devices and plumbing components, PVC granules are integral to creating items that shape our daily lives.

The demand for sustainable materials is increasing. Industries are looking for solutions that balance performance with environmental responsibility. PVC plastic granules offer a compelling option in this context. They can be manufactured in ways that reduce environmental impact due to their adaptability. Manufacturers can minimize their ecological footprint by incorporating recycled content and following strict production standards like the RoHS directive.

Sustainable practices in PVC granule production can address important environmental concerns while preserving the material’s beneficial properties. This makes PVC plastic granules an excellent choice for those who want to make their manufacturing processes more sustainable.

Understanding PVC Plastic Granules and Their Manufacturing Process

What Are PVC Plastic Granules?

PVC granules, also known as polyvinyl chloride granules, are small, cylindrical pellets produced from the polymerization of vinyl chloride monomer. These granules serve as a versatile raw material for various manufacturing processes. The composition typically includes:

- PVC resin: The primary component.

- Plasticizers: To impart flexibility.

- Stabilizers: For thermal stability.

- Fillers and pigments: To achieve desired aesthetic and mechanical properties.

The final properties of PVC granules can be tailored by adjusting the proportions and types of additives, making them suitable for numerous applications.

Manufacturing Process

The production of PVC granules involves several key stages:

1. Polymerization

- Suspension Polymerization: The most common method where vinyl chloride monomer is dispersed in water with suspending agents and initiators to form PVC resin particles.

- Emulsion Polymerization: Used for producing finer particles, essential for specific applications.

2. Compounding

The PVC resin is mixed with additives such as plasticizers, stabilizers, fillers, and pigments. This step ensures that the granules meet specific requirements based on their intended use.

3. Extrusion

The compounded mixture is fed into an extruder equipped with a single or twin screw. Here, the material is melted and homogenized under controlled temperatures and pressures.

4. Pelletizing

The molten PVC compound is then passed through a die to form continuous strands which are subsequently cooled and cut into uniform granules using pelletizers.

5. Quality Control

Rigorous testing is carried out to ensure that the produced granules meet industry standards regarding size, composition, and performance characteristics.

Understanding the detailed composition and precise manufacturing process of PVC plastic granules sets the stage for exploring their diverse applications across various industries.

Diverse Applications of PVC Plastic Granules

PVC plastic granules are widely used in many industries because they are versatile and have useful properties. Here are some examples of how they are used:

1. Footwear Industry

PVC granules are used by manufacturers to make soles, sandals, and boots. These footwear products are not only strong and durable but also flexible and comfortable. PVC’s ability to be both rigid and soft makes it perfect for creating different types of shoes.

2. Construction Sector

In the construction industry, PVC plastic granules are important for making pipe fittings. These fittings are crucial for plumbing systems because they can resist corrosion and damage from chemicals. PVC granules are also used to make cost-effective and waterproof flooring for homes and businesses.

3. Automotive Industry

PVC plastic granules have benefits for the automotive industry too. They are used to coat cables in vehicles, providing insulation and protection against wear and tear. This is especially important for wiring systems that need to withstand heat and moisture.

4. Household Items

PVC’s usefulness extends to everyday household items like garden hoses. Hoses made from PVC granules are popular because they are lightweight, flexible, and don’t easily get tangled, making them easy to use for gardening.

Benefits of Using PVC Plastic Granules

Here are some advantages of using PVC granules in manufacturing:

- Durability: Products made with PVC granules last a long time.

- Versatility: PVC can be molded into different shapes, both hard and soft.

- Chemical Resistance: PVC is able to withstand exposure to harsh chemicals, making it suitable for certain applications.

- Cost-effectiveness: Using PVC as a material is affordable without sacrificing quality.

- Ease of processing: PVC is easy to work with during manufacturing because it can adapt to different processes.

By understanding the various uses and advantages of PVC plastic granules, manufacturers can make better decisions and improve their products in different industries.

Examining the Environmental Sustainability of PVC Plastic Granules

Sustainable Materials and Environmental Impact

The sustainability of PVC plastic granules often comes under scrutiny due to concerns about their environmental impact. Critics argue that PVC production involves toxic additives and the release of hazardous chemicals, raising questions about its eco-friendliness. However, it’s important to delve deeper into these claims to understand their validity.

Perceived Environmental Concerns

- Toxic Additives: Traditional PVC manufacturing has been associated with the use of harmful additives like phthalates and heavy metals. These substances can pose environmental and health risks if not managed properly.

- Chemical Release: During the production and disposal of PVC products, there is potential for the release of dioxins and other hazardous chemicals. This has led to concerns over air and water pollution.

While these issues are significant, advancements in technology and stringent regulations have led to more sustainable practices within the industry.

Industry Initiatives for Enhanced Sustainability

Several initiatives aim to mitigate the environmental concerns associated with PVC plastic granules:

- Adherence to RoHS Standards: The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electrical and electronic products. Many manufacturers now comply with RoHS standards, reducing the presence of dangerous substances in PVC granules.

- Development of Eco-Friendly Additives: Innovations include the creation of non-toxic, bio-based plasticizers as alternatives to traditional phthalates. These eco-friendly additives contribute to making PVC granules safer for both human health and the environment.

- Recycling Programs: Recycling initiatives have been implemented to reduce waste generated from PVC products. By recycling used PVC materials into new granules, manufacturers can decrease reliance on virgin resources and minimize landfill waste.

- Energy-Efficient Production Processes: Advances in manufacturing technology have led to more energy-efficient production methods. Lower energy consumption not only reduces carbon emissions but also lowers overall production costs, benefiting both the environment and manufacturers.

Understanding these efforts helps paint a clearer picture of how PVC plastic granules can align with sustainable material goals.

Key Advantages of Using PVC Plastic Granules in Manufacturing

PVC plastic granules offer many benefits in manufacturing because of their excellent mechanical and electrical properties. Products made with PVC granules are highly durable, making them suitable for tough industrial applications.

Mechanical and Electrical Properties

PVC granules have outstanding qualities that make them ideal for manufacturing:

- Mechanical Properties: PVC granules have excellent tensile strength, toughness, and resistance to abrasion. These properties make them perfect for products that need to be strong and long-lasting. For example, PVC is commonly used to protect cables (cable jacketing) so that they can withstand harsh conditions without getting damaged.

- Electrical Properties: PVC has great insulation properties, making it a preferred choice for electrical applications. It has low conductivity, which helps prevent electrical failures and ensures safety. This makes PVC granules particularly useful in making flexible tubing for wiring and electronic components.

Advantage of Soft Jacketing

One unique advantage of PVC plastic granules is their ability to create ‘soft jacketing’. This property is especially beneficial in certain industries:

- Healthcare: In the medical device manufacturing industry, the flexibility and softness of PVC are crucial. Soft jacketing provides a gentle yet durable covering for medical devices such as catheters and tubing. This flexibility ensures patient comfort without compromising on safety or performance.

- Consumer Goods: Products like waterproof gear and toys benefit from the soft jacketing provided by PVC granules. The material’s pliability ensures these items are user-friendly while maintaining high durability standards.

By using these mechanical and electrical properties effectively, manufacturers can create top-notch products that meet industry requirements. The versatility of PVC granules for different manufacturing needs highlights their importance in improving modern manufacturing practices.

Optimizing Product Quality: Considerations for Working with PVC Plastic Granules

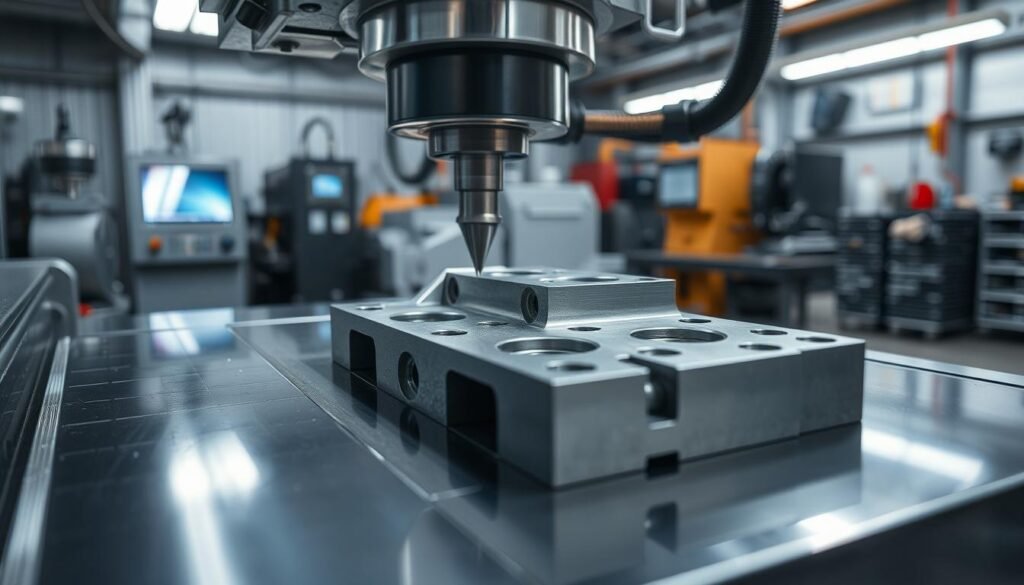

Ensuring high-quality outcomes when working with PVC plastic granules begins with the selection of appropriate machinery. Single-screw extruders are widely used in the processing of PVC granules due to their efficiency and consistency. These machines facilitate the melting and shaping of granules, ensuring uniform material flow and reducing the likelihood of defects.

Key process parameters such as the L/D ratio (length-to-diameter ratio) and molding temperature play critical roles in achieving optimal product quality. The L/D ratio impacts the shear stress applied to the granules, influencing their melting behavior and final properties. An optimal L/D ratio ensures adequate mixing and homogenization of the material.

Molding temperature is equally crucial; it must be carefully controlled to prevent degradation while ensuring proper flow characteristics. Incorrect temperatures can result in poor surface finish or compromised mechanical properties.

Effective Quality Control Measures

Implementing stringent quality control measures helps mitigate potential issues associated with PVC granule utilization:

- Regular Calibration of Equipment: Ensures machinery operates within specified parameters.

- Material Testing: Conduct tests on incoming granules to verify their composition and properties.

- Process Monitoring: Utilize sensors and monitoring devices to track critical parameters like temperature and pressure during processing.

- Sample Testing: Perform regular inspections on finished products to detect any anomalies early.

By focusing on these considerations, manufacturers can significantly enhance product quality, ensuring consistency and reliability across various applications.

Looking Ahead: Future Innovations and Emerging Trends in PVC Plastic Granules

Ongoing research efforts in PVC plastic granule technology are pushing the boundaries of what this versatile material can achieve. A significant area of focus is the development of nucleating agents. These agents play a crucial role in enhancing the mechanical properties of PVC by promoting uniform crystal formation during the cooling process. The benefits include improved clarity, increased strength, and better heat resistance.

Compatibility with other polymers like polyethylene is another exciting frontier. Researchers are continuously exploring ways to blend PVC with polyethylene to create hybrid materials that combine the best properties of both. This approach can lead to new applications where flexibility, durability, and cost-effectiveness are paramount.

Future Applications and Market Trends

Emerging trends indicate that PVC plastic granules will continue to gain traction across various industries due to their adaptability and sustainable potential:

- Medical Devices: The healthcare sector stands to benefit from innovations such as cross-linked PVC, which offers enhanced biocompatibility and durability for medical tubing and devices.

- Construction Materials: Advances in fire-resistant and UV-stabilized PVC compounds are making them increasingly popular for outdoor applications like siding and window frames.

- Automotive Industry: Lightweight yet durable PVC composites are being developed for use in vehicle interiors, contributing to overall weight reduction and fuel efficiency.

Potential Game-Changers

Several groundbreaking innovations could redefine the landscape for PVC granules:

- Cross-Linking Technology: Cross-linking enhances the thermal stability and chemical resistance of PVC, making it suitable for high-performance applications.

- Bio-Based Additives: As sustainability becomes a priority, bio-based additives are being integrated into PVC formulations to reduce environmental impact without compromising performance.

- Smart Materials: Research is also delving into the creation of smart PVC materials that can change properties in response to environmental stimuli, opening up possibilities for responsive surfaces and adaptive structures.

The future of PVC plastic granules looks promising, driven by continuous innovation and evolving market demands. These advancements not only enhance material performance but also align with global sustainability goals.

Conclusion

PVC plastic granules play a crucial role in driving the manufacturing industry towards a sustainable future. These granules are incredibly versatile and long-lasting, making them highly effective in a wide range of industries. When we produce and use PVC granules responsibly, they bring numerous environmental advantages.

It’s essential to explore various sustainable materials for your manufacturing needs. PVC granules are an attractive choice because they offer both excellent performance and sustainability. By taking these factors into account, you can make better decisions that meet both your industrial requirements and environmental obligations.

To embrace sustainable materials fully, it’s important to have a good understanding of them and choose the right components.

FAQs (Frequently Asked Questions)

What are PVC plastic granules and their role in the manufacturing industry?

PVC plastic granules are a type of sustainable material widely used in the manufacturing industry. They play a crucial role in addressing the growing demand for sustainable materials, offering a range of benefits for various applications.

How are PVC plastic granules manufactured?

PVC plastic granules are manufactured through a process that involves several key stages. This process includes the use of polyvinyl chloride and specific manufacturing techniques to produce the granules used in various industries.

What are some examples of products that make use of PVC plastic granules?

PVC plastic granules are utilized in a diverse range of products, including footwear, pipe fittings, polyvinyl flooring, garden hoses, and cable coatings. These products benefit from the performance and durability offered by PVC granules.

What environmental sustainability initiatives are associated with PVC plastic granules?

There have been concerns regarding the environmental impact of PVC plastic granules, but industry initiatives aim to enhance sustainability. Adherence to standards like the RoHS (Restriction of Hazardous Substances) directive is one such initiative to address these concerns.

What advantages do products made with PVC plastic granules offer?

Products made with PVC granules exhibit notable mechanical and electrical properties, making them valuable for various industrial applications. Additionally, PVC granules offer the unique advantage of ‘soft jacketing,’ particularly relevant in sectors like healthcare (medical device manufacturing).

How can manufacturers optimize product quality when working with PVC plastic granules?

Manufacturers can optimize product quality by using appropriate machinery (e.g., single-screw extruders), maintaining optimal process parameters (L/D ratio, molding temperature), and implementing effective quality control measures. These considerations are essential for ensuring good outcomes when utilizing PVC granules.

What future innovations and emerging trends are associated with PVC plastic granules?

Ongoing research efforts focus on areas such as the development of nucleating agents to enhance material properties and compatibility with other polymers like polyethylene. Additionally, potential future applications and market trends may further shape the demand for PVC granules as a sustainable choice in manufacturing.

How can PVC plastic granules contribute to advancing towards a more sustainable future for the industry?

PVC plastic granules play a key role in advancing towards a more sustainable future for the industry by offering benefits while balancing the need for responsible production and usage. It is encouraged to explore the diverse range of sustainable materials available, considering PVC granules as one viable option among others.