Plastic injection molding machines have revolutionized the manufacturing industry by enabling the mass production of complex plastic parts with high precision and efficiency. In this comprehensive guide, we will explore the world of plastic injection molding machines, covering their working principles, key components, applications, and best practices for optimal performance.

What are Plastic Injection Molding Machines?

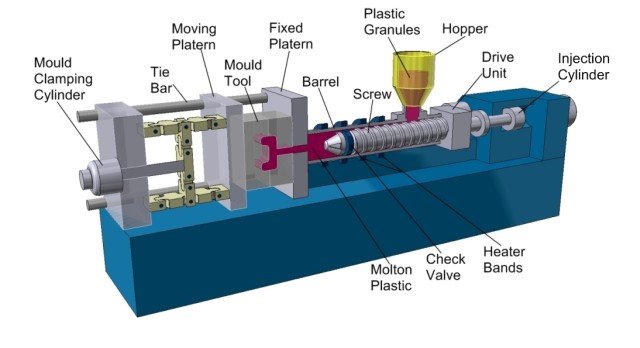

Plastic injection molding machines, also known as injection presses, are sophisticated equipment used to manufacture plastic parts by injecting molten plastic material into a mold cavity. These machines consist of several essential components that work together to produce high-quality plastic parts consistently and efficiently.

Key Components of Plastic Injection Molding Machines

- Injection Unit: The injection unit is responsible for melting and injecting the plastic material into the mold. It consists of a hopper, a reciprocating screw, a barrel, and a nozzle.

- Clamping Unit: The clamping unit holds the two halves of the mold together during the injection process and applies pressure to prevent the mold from opening due to the high injection pressure.

- Mold: The mold is a custom-designed tool that shapes the molten plastic into the desired part geometry. It consists of two halves – the cavity and the core – which create the external and internal features of the part, respectively.

- Control System: The control system is the brain of the injection molding machine. It monitors and controls various parameters such as injection pressure, temperature, speed, and cooling time to ensure consistent part quality.

How Plastic Injection Molding Machines Work

The plastic injection molding process involves several stages:

- Plasticizing: The plastic material, usually in the form of pellets or granules, is fed into the hopper and then transported by the reciprocating screw through the heated barrel. The combination of heat and mechanical shear from the screw melts the plastic, creating a homogeneous melt.

- Injection: Once the plastic is fully melted, the screw acts as a plunger, pushing the molten plastic through the nozzle and into the mold cavity. The high injection pressure ensures that the melt fills the entire cavity, conforming to its shape.

- Cooling: After injection, the molten plastic begins to cool and solidify inside the mold. The cooling time depends on factors such as the part thickness, material properties, and mold temperature.

- Ejection: Once the part has cooled sufficiently, the mold opens, and the part is ejected from the cavity using ejector pins or a stripper plate. The mold then closes, and the cycle repeats for the next part.

Advantages of Plastic Injection Molding

Plastic injection molding offers several advantages over other manufacturing methods:

- High Efficiency: Injection molding machines can produce large volumes of parts in a short time, making it an ideal choice for mass production.

- Consistency: The automated nature of the process ensures that each part is produced with the same dimensions, appearance, and properties, resulting in high part-to-part consistency.

- Design Flexibility: Injection molding allows for the creation of complex part geometries with intricate features, undercuts, and varying wall thicknesses.

- Material Versatility: A wide range of thermoplastic materials can be used in injection molding, enabling the production of parts with diverse properties such as strength, flexibility, heat resistance, and chemical resistance.

Applications of Plastic Injection Molding Machines

Plastic injection molding machines find applications in various industries, including:

- Automotive: Injection molding is used to produce numerous automotive components such as bumpers, dashboards, door panels, and under-the-hood parts.

- Consumer Products: Many everyday items like toys, household appliances, electronic enclosures, and packaging are manufactured using injection molding.

- Medical Devices: Injection molding is extensively used in the production of medical devices and components, including syringes, IV connectors, and disposable medical equipment.

- Aerospace: High-performance thermoplastics are injection molded to create lightweight and durable components for the aerospace industry.

Choosing the Right Plastic Injection Molding Machine

When selecting a plastic injection molding machine, several factors should be considered:

- Clamping Force: The clamping force required depends on the size and complexity of the mold, as well as the material being molded. It is essential to choose a machine with sufficient clamping force to prevent mold opening during injection.

- Shot Size: The shot size refers to the maximum volume of plastic that can be injected in a single shot. It should be matched to the part size and the material’s flow properties.

- Injection Pressure: The injection pressure determines how quickly and effectively the molten plastic fills the mold cavity. Higher injection pressures are necessary for parts with thin walls or long flow paths.

- Precision and Repeatability: For applications requiring tight tolerances, it is crucial to select a machine with high precision and repeatability to ensure consistent part quality.

Best Practices for Optimal Performance

To achieve the best results from your plastic injection molding machine, consider the following best practices:

- Regular Maintenance: Perform regular maintenance on your machine, including cleaning, lubrication, and replacing worn components to ensure optimal performance and extend the machine’s lifespan.

- Proper Material Handling: Store and handle plastic materials according to the manufacturer’s recommendations to prevent contamination and ensure consistent melt properties.

- Mold Design Optimization: Collaborate with experienced mold designers to optimize the mold design for efficient filling, cooling, and ejection, minimizing cycle times and improving part quality.

- Process Parameter Optimization: Fine-tune process parameters such as injection pressure, temperature, and cooling time to achieve the desired part properties and minimize defects like warpage, sink marks, and flash.

- Operator Training: Invest in training your machine operators to ensure they have the necessary skills and knowledge to operate the machine effectively and troubleshoot issues when they arise.

Conclusion

Plastic injection molding machines are powerful tools for producing high-quality plastic parts efficiently and cost-effectively. By understanding the working principles, key components, and best practices associated with these machines, manufacturers can optimize their production processes and create parts that meet the highest standards of quality and performance.

As the demand for plastic parts continues to grow across various industries, the importance of plastic injection molding machines will only increase. With ongoing advancements in machine technology, materials, and process control, the possibilities for creating innovative and complex plastic parts are virtually limitless.

References:

- “Injection Molding: Process, Defects, and Design Considerations” by Douglas M. Bryce, Society of Plastics Engineers, 2018. Source

- “Injection Molding Handbook” by Tim A. Osswald, Lih-Sheng Turng, and Paul J. Gramann, Hanser Publications, 2008. Source

- “Injection Molding Machine: Components, Working, Types, Applications” by Matmatch, 2021. Source