Tips for Choosing a Polyethylene Recycler

Purchasing a high-quality polyethylene recycling machine is essential for efficient plastic waste management. To help you make an informed decision, here’s a comprehensive guide that covers everything from understanding your specific needs to evaluating the machine’s overall quality.

Understand Your Needs

Production Capacity: Begin by determining the amount of waste you need to process. This will help you choose a machine that matches your production requirements. For instance, if you handle a large volume of polyethylene waste, you’ll need a machine with higher capacity.

Equipment Type: Decide between single-screw and twin-screw machines. Single-screw machines are often more cost-effective, but twin-screw machines offer better processing capabilities and are suitable for more complex materials.

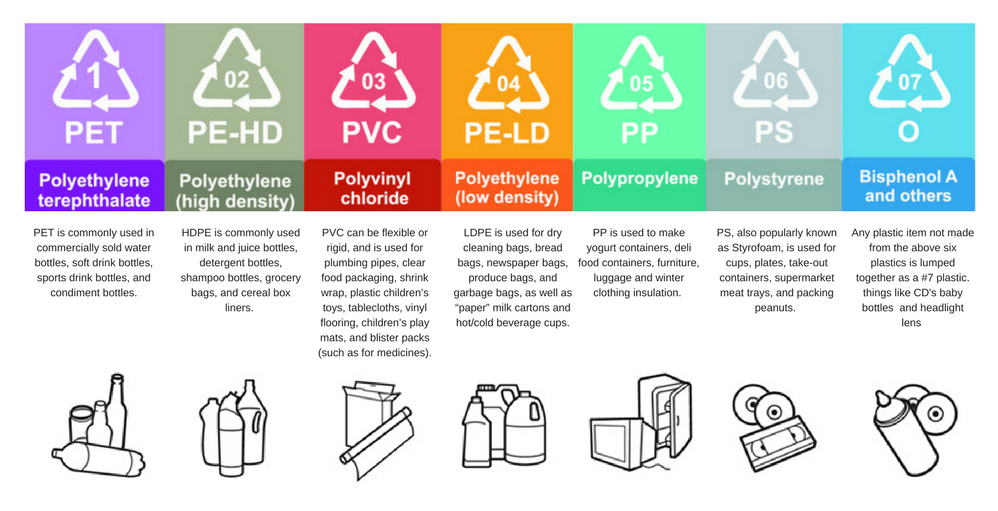

Application Area: Clarify the types of polyethylene waste you will be processing, such as film, bottles, or bags. Different waste types may require different machine configurations.

Evaluate Key Parameters

Screw Design: Pay attention to the screw diameter, length-to-diameter ratio, and overall design. The screw must be designed to handle the specific type of polyethylene waste you process. For example, a larger diameter screw may be required for high-volume operations.

Temperature Control System: Ensure the machine has a reliable heating and cooling system. Moreover, proper temperature control is crucial for efficient processing and maintaining product quality. Consequently, a well-regulated temperature system not only enhances performance but also ensures consistent results in the final output.

Control System: Opt for machines equipped with a PLC touchscreen control system. This feature simplifies operation and allows for precise adjustments.

Brand and Manufacturer

Reputation and Experience: Choose a manufacturer with a strong market reputation and extensive experience in the industry. Furthermore, a well-established company is likely to offer better quality and reliability. This is because they have a proven track record and a deeper understanding of industry standards and customer needs. Consequently, partnering with such a manufacturer can ensure you receive a high-quality product that meets your requirements.

After-Sales Service: Confirm that the manufacturer provides comprehensive after-sales support, including technical guidance and repair services. Good after-sales service can save you time and money in the long run.

Equipment Quality

Materials and Craftsmanship: Examine the materials used in the machine and the quality of its craftsmanship. Additionally, durable materials and high-quality workmanship are essential for ensuring the longevity and reliability of the equipment. By focusing on these aspects, you can be confident that the machine will perform consistently over time and withstand the demands of continuous operation.

Testing and Certification: Select machines that have undergone rigorous testing and hold relevant certifications. Moreover, this guarantees that the machine meets both performance and safety standards. Ensuring these certifications also provides peace of mind that the equipment has been evaluated thoroughly and adheres to industry regulations, enhancing its reliability and effectiveness.

Budget and Costs

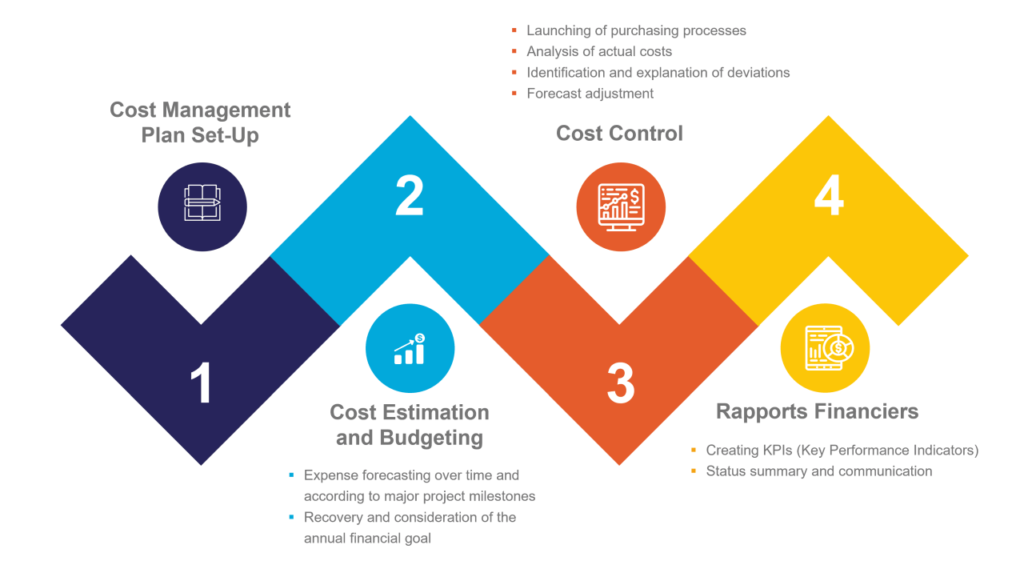

Equipment Cost: Consider the initial purchase price of the machine and its overall value. Balance cost with the machine’s features and capabilities to find the best deal.

Operating and Maintenance Costs: Calculate the long-term costs of operating and maintaining the machine. Additionally, this includes factors such as energy consumption, spare parts, and routine maintenance. By assessing these ongoing expenses, you can better understand the total cost of ownership and ensure that the machine remains cost-effective over its lifespan.

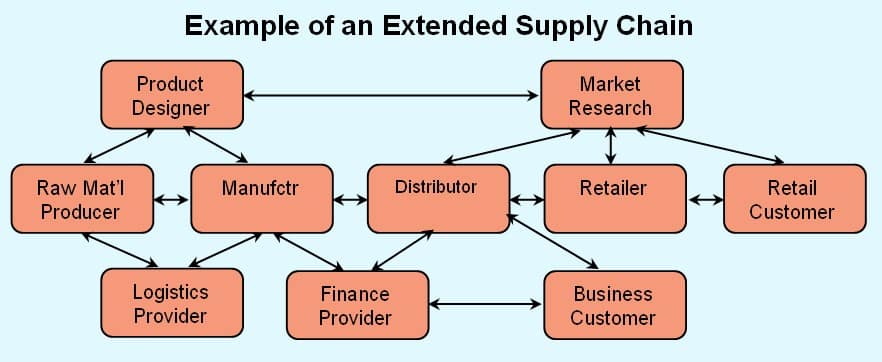

Supplier Support

Technical Support: Ensure the supplier offers robust technical support and training. Furthermore, this will help you effectively operate the machine and resolve any issues that arise. Comprehensive support and training not only facilitate smooth machine operation but also minimize downtime and enhance overall efficiency.

Parts Supply: Verify that spare parts are readily available and easy to obtain. Additionally, efficient parts supply ensures minimal downtime for maintenance and repairs. This helps maintain consistent machine performance and reduces interruptions in your operations.

Conclusion

Buying a high-quality polyethylene recycling machine involves several key considerations, from understanding your specific needs to evaluating equipment quality and supplier support. By following this guide, you can make an informed decision and choose a machine that enhances your recycling operations, ultimately contributing to a more sustainable environment.

Plastic Recycling: An Overview – Comprehensive insights into the plastic recycling process and its benefits.

How Plastic Recycling Works – Detailed explanation of the mechanics and stages involved in plastic recycling.