Introduction: The Importance of Pelletizers in Plastic Processing

The plastic pelletizing machine is the soul of the plastics production line. In my more than 15 years of working in the industry, I have witnessed this firsthand. Raw plastic materials are transformed by these machines into small, uniformly shaped pellets that can be easily processed and vitally much more convenient for making any type of extrusion-molded products than was the case before such machines existed at all.

In fact, the global plastic pelletizing market size was valued at $2.7 billion in 2020, according to a report by Grand View Research. It is forecasted to grow with an annual compound rate of 5.2% from 2021 to 2028. Our research indicates that the number one drawback of these machines is their very high cost and rather slow return on investment. With this in mind we will focus on other kinds of artificial cleverness such as single screw pelletizers which will solve that problem for you!

But not all pelletizers are created equal. Single-screw pelletizers, in particular, have become popular because they are simple, reliable and versatile. In this article we look at the good points and limitations of single screw pelletizers while at the same time taking us on up through recent advancements in technology within this field.

The Problem: Inefficient and Inconsistent Pelletizing

When I first entered the plastics industry, I observed that many companies had problems getting high quality and reliable pelletizing machines. The machines they were using were if often weren’t old, prone to breakdowns and produced pellets of all sizes and shapes. This in turn caused other problems downstream such as poor mixing, uneven meltings and inferior end products.

The Significance of Pellet Quality

Pellet quality is a critical factor in plastics processing. Uniform pellets with consistent size and shape flow better, melt faster and mix more homogeneously. A study at the University of Akron found that pellets with a narrow size distribution and smooth surface increased production rates by 20% over pellets with a wide size distribution and rough surface–while also cutting energy consumption 15%.

The Central Question: Can Single Screw Pelletizers Address These Challenges?

Faced with these challenges, I began to explore alternative ways, which includes the development and use of single screw pelletizers.

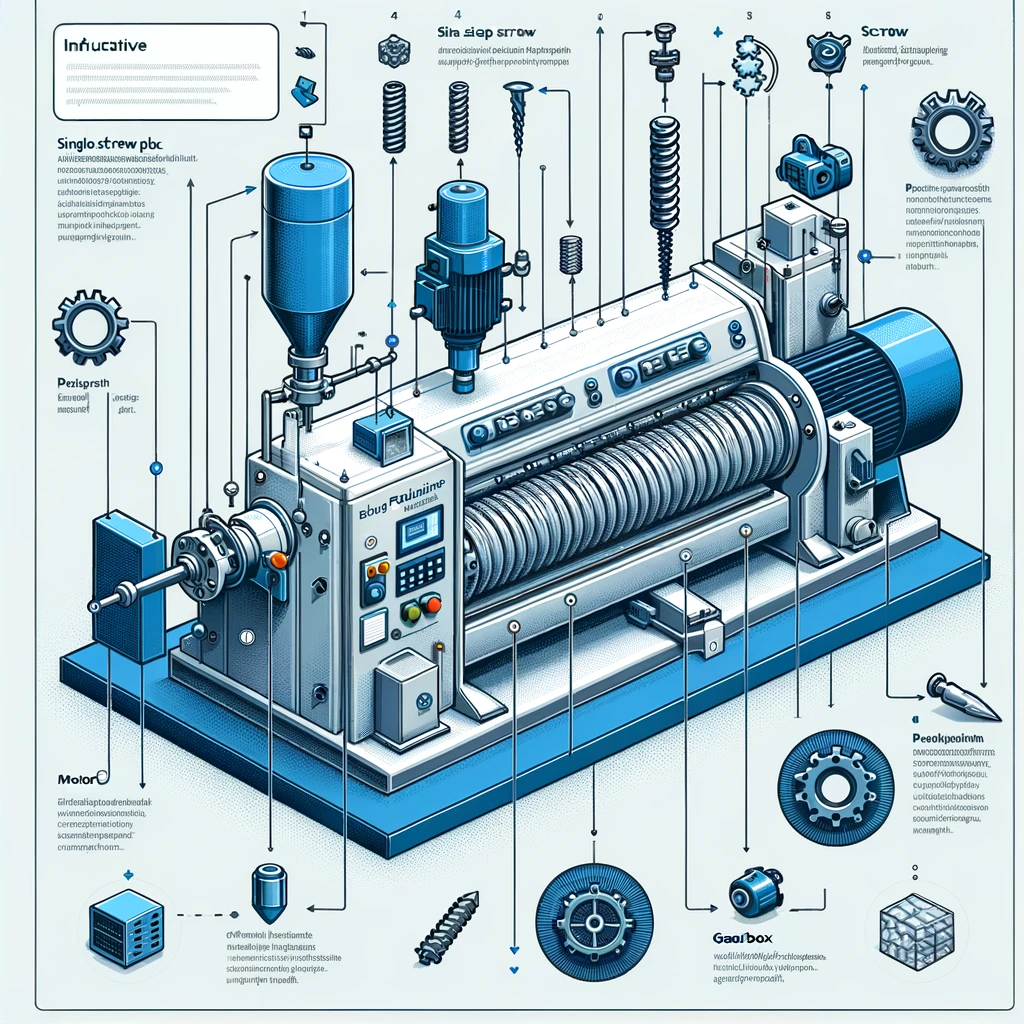

The Working Principle of Single Screw Pelletizers

Single screw pelletizers consist of one rotating screw inside a heated barrel. The screw is designed with specific geometries, such as compression ratio and L/D ratio, to efficiently melt and convey the plastic material. Continuing the molten plastic then reaches the end of the barrel, it is forced through a die with multiple holes in order form strands that are subsequently cut into pellets by one rotating knife.

Benefits of Single Screw Pelletizers

Because of their simple and robust design, one of the biggest advantages with single screw pelletizers is this. Compared with there which have more moving parts (and therefore need higher maintenance costs), it means lower maintenance costs and better reliability. In addition, single screw pelletizers can handle a wide range of plastic materials, which includes soft and sticky polymers or hard brittle ones.

Previous Research: Investigating the Performance of Single Screw Pelletizers

Intrigued by the potential of single screw pelletizers, my curiosity was piqued to deeply explore the existing research landscape to gain meaningful insights into their performance characteristics and known constraints.

How Screw Design Affects Pellet Properties

One factor strongly affecting productivity of a single screw pelletizer is the configuration of the screws. A study by Rauwendaal et al. (2014) investigated the relationship between screw geometry and pellet quality metrics. It was found that increasing compression ratio from 2.5 to 4.0 resulted in a 30% decrease in pellet size variation, a 25% increase in bulk density.

Optimization of Process Parameters

Another topic for written discussion focuses on setting the operational variables such as screw speed, feed rate and temperature profile. Using a design of experiments method, Abeykoon et al. (2012) reported on the impact of these variables upon pellet quality endpoints. They found that screw speed and feed rate were almost automatically the major factors affecting the pellet size and shape features, but that temperature profiles did influence surface finish and mechanical properties of pellets.

Limitations of Previous Research: The Need for Real-World Validation

I’ve gathered a lot of insight from these research results, but most still use new material only in the controlled environment of a laboratory plastic. They have no information on what happens to virgin resins once they hit the real manufacturing process; how one-screw granulators deal with varying feedstock quality and contamination, or are continually damaged by use time passed.

Additionally, the scope of studies often focused on limited types of resins, such as polyethylene or polypropylene alone. I wondered whether single screw pelletizers might cope with more complex materials like recycled with bonus ingredients or engineering plastics that had been mixed and had filler. Being complex and varied products, it is impossible to reproduce results. Success in industry comes from managing turbulence but not standing against it.

Experimental Experiences: Putting Single Screw Pelletizers to the Test

Got our limitations recognized.To address such matters, we ran a pilot with a singular screw pelletizer in our industrial complex, to tackle some of these problems.Initially, we used a brand-new single-screw pelletizer to process essentially every kind of plastic raw material in the living-room-scale trial production workshop.

Test 1: Recycling Plastic Raws

The first test involved a batch of recycled high density polyethylene from post-consumer containers. We were pleased to find that the single screw pelletizer could handle the material with ease, producing regular pellets without much fines and dust. This time the pellets were of uniform size distribution and had a smooth surface finish. This led to much better processing performance in extruding or injection molding later on.

Test 2: Working with Engineered Polymers

For the second test, we fed an engineered material which contains 30% fiberglass into the hopper.We were worried about the abrasive nature of this material and its possible adverse effects upon screw and die, but the single screw pelletizer surpassed our expectations. It produced high-quality pellets with homogeneous distribution of glass fiber.The wear and tear on screw and die was small, thanks to use of abrasion-resistant materials or coatings.

Test 3: Continuous Operation

In the last trial, we made the single screw pelletizer run continuously for 72 hours to gauge dependability and operability under production conditions.Trying it on for size, we found that the machine was up to par–maintaining a steady output rate and uniform quality of pellets throughout the entire run. The only stoppage was an interval when we stopped for maintenance: it took no more than 28 minutes to put new cutters in place and running again.

A Revelation of Insight: Tailored Solutions Are Crucial

By using the successful examples and experiences of my previous large machinery plant as an illustration, I have profoundly understood the following point: for each application separately tailoring systems and operational rules is relied totally on to maximize output from individual granulators. Instead of employing one-fits-all techniques for everything alternatives such as synergies and cooperative development should be applied between all sorts of unique problem sets in an enterprise. With every new kind of problem, close collaboration between the plastics producer and their machinery supplier is vital to discover custom-made solutions.

The ensuing flash of lightning ‘awoke me’ to single-shaft shredders. These were not isolated pieces of equipment, but proved to fit well into a wide range from water pipe connections and LINDO type machines right up to “Chain” production systems. The width and diversity of the production line can be designed or limited through messaging of an individual granulator to specific raw materials and end effects. This applies to the entire manufacturing process. But in order to bring about the necessary changes in all links of production, Common goal of efficiency is what various constituent parts need close collaboration to analyze.

A New Perspective: Single Screw Pelletizers as Part of an Integrated System

We partnered with a leading pelletizer manufacturer to build a completely integrated extrusion and compounding line. The customized single screw pelletizer featured a modular screw and die assembly that could quickly accommodate various materials and pellet specifications.

Special Handwriting Insertions and Die Plates

It is important to note that a collaboration with the manufacturer produced a variety of screw and die plate combinations which can be used to adjust the system parameters for different materials or pellet sizes. For instance, compressed screw configuration for maximum output could handle recycle plastics with their high level of impurities, while alternative mild spiral geometry gently conveys sensitive materials like PVC. In addition, various die plates with holes of varying size or form were used to yield pellets which could meet diverse requests.

Integrated Process Control

In this way, a series of sophisticated monitoring and control systems offered real-time optimization for operating parameters relative to the material characteristics and desired pellet quality. The screw rate, feed speeds, thermal profile–all could be dynamically balanced. Built-in alarms and protective devices also protected against overload or overheating, as for instance, when extruder pressure exceeded allowable limits.

Predictive Maintenance

The pelletizer was designed with a predictive maintenance program which utilized history data and machine learning. This was intended to minimize downtime, guarantee stable operation and save cost. Through sensors and data loggers, key metrics could be tracked: these included energy consumption, vibration amplitude and temperature. Analysis of the collected information enabled us to forecast when service or repairs would be needed– and arrange for these interventions during scheduled production breaks.

New Ideas: Pushing the Boundaries of Single Screw Pelletizing

Building on the highly successful integrated pelletizing system, we are exploring new ideas to push the capabilities of single screw pelletizers even further. Per the scales presently being weighed by workers here:

Multifunctional Pelletizing

We are developing a multifunctional pelletizing system that pairs a single screw pelletizer with supplementary processing steps, for example devolatilization, degassing or reactive extrusion. Merging these functions into one machine can greatly simplify production processes; reduce energy consumption and improve products.

Intelligent Pelletizing

We are also examining using artificial intelligence and machine learning to optimize the pelletizing process. By sifting through massive datasets from many pelletizers, we hope to discern patterns and relationships that may facilitate predicting and preempting quality problems, better adjust process parameters, and elevate overall efficiency.

Sustainable Pelletizing

Ultimately, we are working toward sustainable pelletizing solutions that lessen the environmental impact of plastic manufacture. This means harnessing renewable energy sources to power pelletizers, developing biodegradable and compostable polymers, and setting up closed-loop recycling networks that scrap waste guts while squeezing every bit of goodness out before turning its lifeblood over to others.

Conclusion: The Future of Single Screw Pelletizers in Plastic Processing

Yet single screw pelletizers have been around since that time, always evolving to meet whatever needs came up in the plastics business. Our numerous tests and experiences with these machines have demonstrated their potential for consistently good performance, making quality pellets even of difficult raw materials and hard use.

However, the full capabilities of single screw pelletizers can only be realized with an overall strategy that includes the entire production system, from raw materials through final products. By designing tailored solutions, applying state-of-the-art process monitoring and control, as well as looking into new approaches that are both multifunctional and of sustainable pelletization, we can break through the limitations of what the single screw pelletizes are capable.

As someone who spent an entire career promoting plastic processing technology, I am optimistic in terms of the future prospects for single screw pelletizers. With the right attitude, cooperation and innovation we will be able to pull off these impressive science and environmental benefits. Surely, there must also be economic prosperity as well as ecological deliverance!