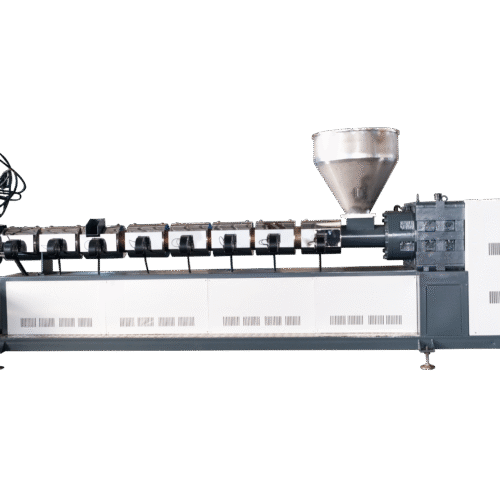

The PVC Pelletizing Machine is a state-of-the-art piece of equipment designed for the efficient conversion of polyvinyl chloride (PVC) materials into uniform, high-quality pellets. This machine is ideal for manufacturers looking to streamline their production processes and ensure consistency in their end products.

Key Features

1. High Production Capacity:

Our PVC Pelletizing Machine boasts a production capacity that meets the demands of large-scale manufacturing. It can handle substantial quantities of PVC material, converting them into pellets quickly and efficiently.

2. Advanced Control System:

Equipped with a user-friendly PLC touchscreen control system, the machine allows operators to easily monitor and adjust the production process. This ensures optimal performance and minimal downtime.

3. Robust Construction:

Built with durability in mind, the machine features a sturdy frame and high-quality components that can withstand continuous operation. The screw and barrel are crafted from wear-resistant materials, ensuring a long service life.

4. Energy Efficiency:

Our machine is designed to be energy-efficient, reducing operational costs and environmental impact. It incorporates advanced technologies that minimize energy consumption while maintaining high productivity.

5. Versatility:

The PVC Pelletizing Machine can process a variety of PVC materials, including rigid and flexible PVC, making it a versatile choice for manufacturers. It can also be customized to meet specific production requirements.

Technical Specifications

- Production Capacity: Up to 500 kg/h

- Screw Diameter: 100 mm

- L/D Ratio: 28:1

- Motor Power: 75 kW

- Heating Zones: 4

- Cooling System: Air and water cooling

- Pelletizing Method: Die-face cutting

- Control System: PLC with touchscreen interface

Applications

This machine is suitable for a wide range of applications, including:

- Pipe and Profile Extrusion: Converting PVC waste from pipe and profile production into reusable pellets.

- Film and Sheet Production: Recycling PVC film and sheet scrap into high-quality pellets.

- Injection Molding: Preparing PVC pellets for use in injection molding processes.

Benefits

1. Enhanced Product Quality:

The PVC Pelletizing Machine ensures uniform pellet size and consistency, which is crucial for downstream processing.

2. Cost Savings:

By converting PVC waste into reusable pellets, manufacturers can reduce material costs and minimize waste disposal expenses.

3. Environmental Sustainability:

Recycling PVC materials helps reduce the environmental impact of plastic waste, contributing to a more sustainable manufacturing process.

Conclusion

The PVC Pelletizing Machine is an essential tool for manufacturers looking to optimize their production processes and improve the quality of their PVC products. With its high production capacity, advanced control system, and robust construction, this machine delivers reliable performance and exceptional results. Whether you are recycling PVC waste or producing new PVC products, our pelletizing machine is the perfect solution for your needs.