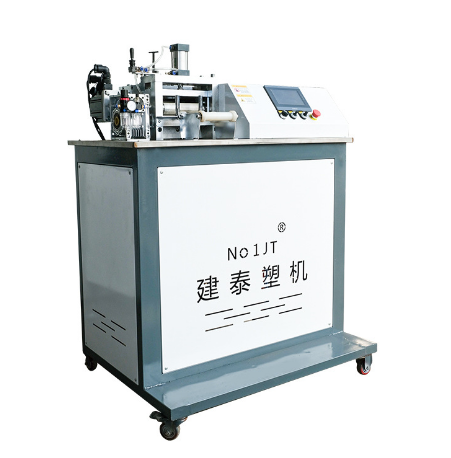

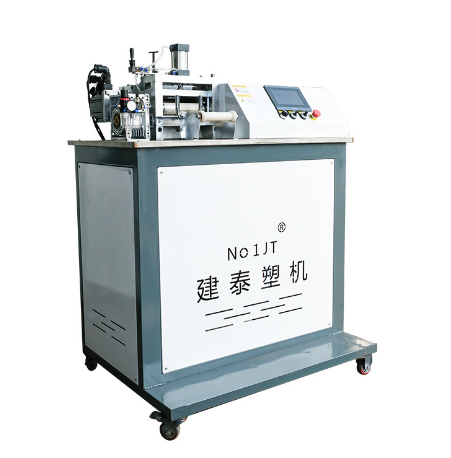

JT-SJP Series Plastic Pelletizer: A Revolution in Plastic Processing

Our JT-SJP series plastic pelletizers offer a versatile and reliable solution for converting plastics into uniform pellets. Here’s a closer look at our model range and their specifications:

| Model | L/D Ratio | Output (kg/h) | Screw Speed (rpm) | Power (kW) | Center Height (mm) |

|---|---|---|---|---|---|

| JT-45 | 28:1 | 25-30 | 10-120 | 7.5 | 650 |

| JT-65 | 28:1 | 55-70 | 10-120 | 11 | 650 |

| JT-80 | 28:1 | 100-120 | 10-120 | 18.5 | 700 |

| JT-90 | 28:1 | 120-140 | 10-120 | 22 | 730 |

| JT-100 | 28:1 | 140-170 | 10-120 | 30 | 750 |

| JT-110 | 28:1 | 180-220 | 10-120 | 37 | 750 |

| JT-120 | 28:1 | 220-260 | 10-120 | 45 | 750 |

| JT-130 | 28:1 | 270-330 | 10-120 | 55 | 800 |

| JT-140 | 28:1 | 350-420 | 10-120 | 75 | 800 |

| JT-150 | 28:1 | 450-550 | 10-120 | 90 | 800 |

| JT-160 | 28:1 | 550-650 | 10-120 | 110 | 850 |

| JT-180 | 28:1 | 800-950 | 10-120 | 150 | 900 |

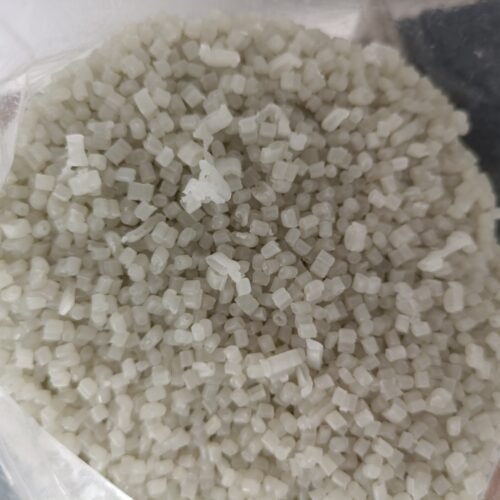

Applications:

This machine is primarily used for pelletizing thermoplastics such as PC, PA, ABS, PP, PS, PE, PVC, PP-R, POM, PBT, and PET. Different screws can produce different types of plastics, and with various dies and auxiliary equipment, it can also extrude wire, film, pipes, sheets, and threads.

Why Choose JianTai’s Plastic Pelletizing Machines?

1. Exceptional Output Ranges

From the compact JT-SJP-45, capable of producing 25-30 kg/h, to the robust JT-SJP-180, delivering up to 950 kg/h, our machines cater to various production needs. Whether you are a small-scale operator or a large manufacturing unit, there’s a JianTai pelletizer suited for your requirements.

2. Optimized Screw Speed and Power Efficiency

Our machines feature adjustable screw speeds ranging from 10 to 120 rpm, allowing precise control over the pelletizing process. Combined with power ratings from 7.5 kW to 150 kW, our pelletizers provide the perfect balance between performance and energy efficiency, ensuring maximum productivity with minimal operational costs.

3. Reliable L/D Ratio for Consistent Quality

The 28:1 L/D ratio across all models ensures thorough plasticization and homogenization, resulting in uniform, high-quality pellets that meet the stringent demands of modern manufacturing processes. This consistency translates into better product quality and reduced waste in subsequent stages of production.

4. Designed for Operational Excellence

With center heights varying from 650 mm to 900 mm, our pelletizers are designed for easy integration into existing production lines. Their compact yet robust design makes them adaptable to various working environments, enhancing workflow efficiency and operational ease.

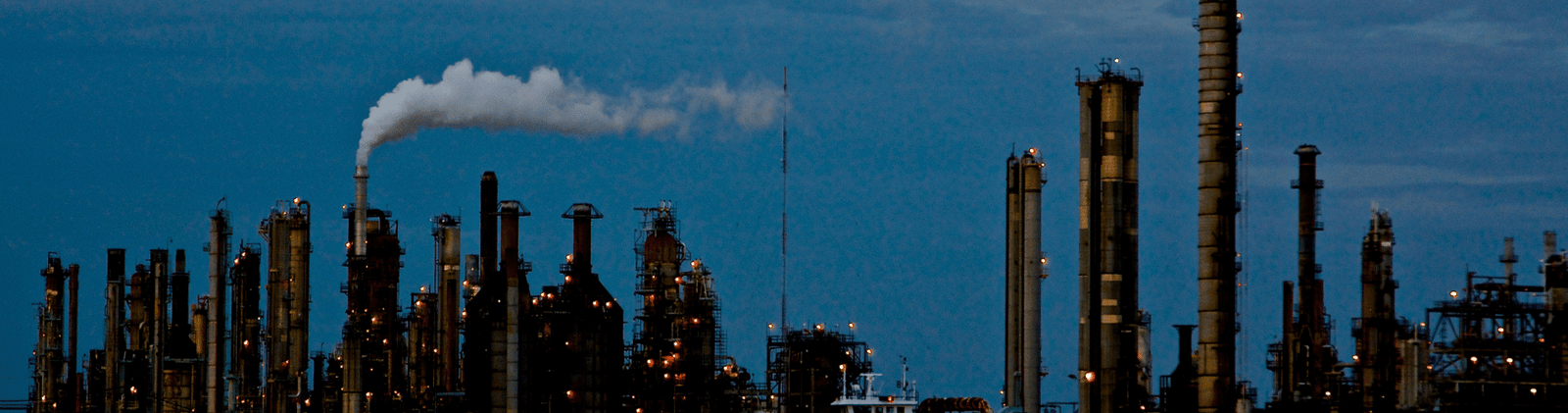

Applications Across Industries

Our plastic pelletizing machines are ideal for a range of applications:

- Plastic Manufacturing: Convert raw or recycled plastic into pellets for use in injection molding, blow molding, and extrusion.

- Recycling Plants: Efficiently process recycled plastics into high-quality pellets, ready for reuse in manufacturing.

- Chemical Engineering: Use in compounding and material blending processes to achieve precise formulations.

Commitment to Quality and Service

At JianTai, we are committed to delivering machines that embody the highest standards of engineering excellence. Each plastic pelletizer is crafted with precision and rigorously tested to ensure reliability and performance. Our customer support team is dedicated to providing comprehensive after-sales service, ensuring that your operations run smoothly.

Plastic Recycling Machine Screws

The screws and barrels of plastic recycling machines are crucial components that determine the efficiency and longevity of the machinery. JianTai, a renowned brand in the plastic machinery industry, manufactures these components with precision and high-quality materials.

Materials:

- Screw and Barrel Material: 38CrMoAlA

- Heat Treatment: Nitriding and Quenching

JianTai’s screws and barrels are produced in Zhoushan, a city known for its expertise in manufacturing high-performance machine parts. The use of 38CrMoAlA steel, treated with nitriding and quenching processes, ensures exceptional hardness, wear resistance, and durability, making these components ideal for high-demand plastic recycling applications.

PLC Touch Screen Control System

The PLC touch screen control system is a state-of-the-art feature integrated into JianTai’s plastic recycling machines, enhancing user experience and operational efficiency.

Features:

- User-Friendly Interface: The touch screen provides an intuitive and interactive interface, making it easy for operators to monitor and control the machine.

- Precision Control: The PLC (Programmable Logic Controller) ensures precise control over the machine’s functions, allowing for fine-tuning of processes to achieve optimal performance.

- Real-Time Monitoring: Operators can view real-time data on machine performance, including temperature, pressure, and production metrics, directly on the screen.

- Automated Processes: The system allows for automation of various processes, reducing the need for manual intervention and minimizing the risk of human error.

- Diagnostic Capabilities: Built-in diagnostics help quickly identify and troubleshoot issues, ensuring minimal downtime and efficient maintenance.

John D., Operations Manager at GreenCycle Industries –

The HDPE Plastic Recycling Machine has transformed our recycling process. We’ve seen a significant increase in our output of high-quality recycled pellets, and the machine’s efficiency has cut down our energy costs dramatically. It’s easy to operate and incredibly reliable, making our day-to-day operations much smoother. We couldn’t be happier with our investment!

Zhang Mei, Production Supervisor at EcoPlast Solutions –

We’ve been using JianTai’s HDPE Plastic Recycling Machine for over a year, and it’s been a fantastic addition to our facility. The machine’s intuitive interface makes it easy to operate, and its robust construction has held up excellently under continuous use. The recycled HDPE pellets are top-notch, and we’ve seen a notable decrease in waste. I highly recommend JianTai’s machine to anyone in the recycling sector.