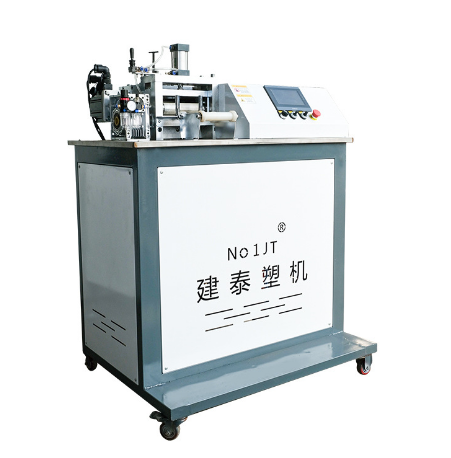

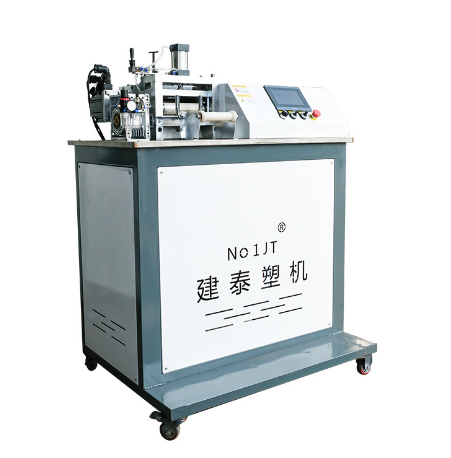

The Jiantai Newest Recycled Plastic Extruder represents a leap forward in the field of plastic recycling. This advanced machine plays a crucial role in transforming waste plastics into valuable, reusable materials. By leveraging cutting-edge technology, it ensures that the process of recycling plastics is efficient and sustainable.

Plastic recycling is vital for reducing waste and protecting the environment. It helps decrease the amount of plastic waste that ends up in landfills and oceans, mitigating pollution and conserving natural resources. Adopting recycled plastic extruders like the Jiantai model, which integrates mechanical recycling methods, can significantly enhance plastic waste management and contribute to these efforts.

Using a recycled plastic extruder such as the Jiantai Newest model offers several benefits:

- Energy Efficiency: Reduces power consumption by up to 30%, making the recycling process more cost-effective.

- Advanced Technology: The extrusion machine screw adopts military forging technology, ensuring durability and high performance.

- Environmental Impact: Facilitates closed-loop recycling systems, contributing to circular manufacturing practices.

Investing in this type of technology not only supports environmental sustainability but also enhances operational efficiency and cost savings for manufacturers.

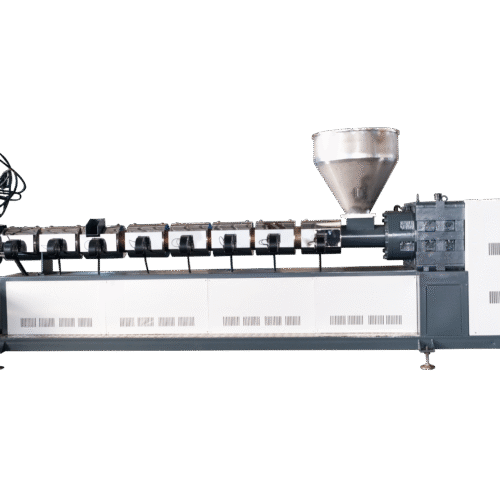

Understanding the Process of Recycled Plastic Extruder

Recycled plastic extrusion is a transformative plastic extrusion process that converts waste plastics into reusable materials. By using a recycled plastic extrusion machine, you can turn discarded plastic items into new products, reducing landfill waste and preserving resources.

Key Steps in Recycled Plastic Extruder

1.Collection and Sorting:

Gather waste plastics, primarily post-consumer waste, from various sources.

Sort them by type and quality to ensure consistency in the final product.

2.Washing and Drying:

Thoroughly clean the sorted plastics to remove impurities.

Dry the plastics to remove moisture, which can affect the extrusion process.

3.Shredding:

Shred the cleaned plastics into smaller pieces to prepare for melting.

4.Melting:

Heat the shredded plastic in the extruder until it becomes molten.

Maintain a steady temperature for smooth processing.

5.Extrusion:

Force the molten plastic through a specially designed die, shaping it into pipes, sheets, or profiles.

Cool and solidify the extruded plastic to maintain its shape.

Cutting and Finishing:

Cut the extruded product into specific lengths or sizes.

Add any final touches to improve its appearance and function.

Importance of an Efficient Extruder Machine

Using a high-quality plastic recycling extruder machine like Jiantai’s newest model offers several advantages:

- Energy Efficiency: Jiantai’s machine reduces power consumption by up to 30%, making the extrusion process more cost-effective.

- Precision Engineering: The single screw design uses advanced forging technology, ensuring durability and precision when processing different types of recycled plastics.

- Consistent Quality: A reliable extruder maintains steady temperatures and pressures, resulting in consistent product quality.

- Reduced Waste: An efficient machine minimizes material waste, promoting more sustainable manufacturing practices.

Investing in a top-tier precious plastic extrusion device not only improves productivity but also supports environmental conservation efforts by making plastic recycling more practical and effective.

The Many Uses of Recycled Plastic Extruder Products

Recycled plastic extrusion is a powerful process that can be used in many different industries. By using a recycling extruder machine, you can create a wide variety of recycled products that not only meet industry standards but also help the environment

Types of Products That Can Be Made

- Pipes and Tubes:

- Recycled plastics are great for making strong pipes and tubing. These are often used in plumbing, irrigation, and drainage systems.

- They can resist corrosion and chemicals well, which makes them suitable for homes and businesses.

- Plastic Sheets:

- Extruded plastic sheets made from recycled materials are used in packaging, construction, and the automotive industry.

- These sheets can be turned into containers, protective linings, or even parts for vehicles.

- Profiles:

- Custom profiles made from recycled plastics have many uses like window frames, door sills, and decorative trims.

- Profiles created through extrusion processes are strong but lightweight, which makes structures more stable.

- Filaments for 3D Printing:

- The popularity of 3D printing has increased the need for recycled plastic filaments.

- These filaments are cheaper and better for the environment compared to new materials.

- Plastic Lumber:

- Manufacturers can use an extruder plastic recycling system to make plastic lumber for decks, fences, and furniture.

- This lumber lasts a long time and doesn’t need much upkeep like regular wood.

Benefits of Using Recycled Plastics

Using recycled plastics has many advantages:

- Saves Money: Making products from recycled plastics costs less than using new materials.

- Helps the Earth: Reducing the amount of plastic waste in landfills and oceans has a positive impact on the environment.

- Flexible: Recycled plastics can be used for many different manufacturing purposes because they can be designed and shaped in various ways.

Common Problems Solved by Good Extruder Machines

A good extruder machine ensures that products are made consistently and with few mistakes. It helps with common issues like:

- Controlling Moisture: Twin screw extruders are particularly effective in controlling moisture by enhancing filtering and degassing, ensuring the plastic shredder and extruder work well together to prevent problems caused by moisture.

- Keeping Materials the Same: Advanced machines, especially twin screw extruders, give better control over how materials behave, which leads to more consistent products.

Investing in a top-notch recycling extruder machine like Jiantai’s model is a smart move for any business. It improves production capabilities while also showing a commitment to protecting the planet.

Advantages and Challenges in Recycled Plastic Extruder

Assumptions and Calculation Example: Using Electricity Savings to Purchase a New Machine

1. Basic Assumptions

- Machine Price: $20,000

- Energy Savings Rate: 30%

- Electricity Cost: $0.10/kWh

- Machine Power Consumption: 500 kW (per hour)

- Daily Operating Time: 8 hours

- Annual Operating Days: 250 days

Chart Information

To clearly present this calculation, you can create a chart with the following key points:

Parameter Value Machine Price $20,000 Energy Savings Rate 30% Electricity Cost $0.10/kWh Machine Power Consumption 500 kW Daily Operating Time 8 hours Annual Operating Days 250 days Total Electricity Cost (without savings) $100,000/year Electricity Cost (with savings) $70,000/year Annual Savings $30,000/year Payback Period 0.67 years (about 8 months)

Common Challenges Faced in Recycled Plastic Extruder

While there are many benefits, manufacturers often encounter several challenges during the recycling process:

- Moisture Control Issues: Moisture in recycled plastics can cause defects in the final product. Efficient drying systems are essential to prevent this problem.

Effective moisture control is crucial for achieving high-quality extruded products.

- Difficulties with Certain Plastics: Not all types of plastics are easily recyclable. For instance:

- Polyvinyl Chloride (PVC): Requires careful handling due to its chlorine content.

- Mixed Plastics: Sorting different types of plastics before recycling can be labor-intensive and costly.

Advanced machines like the Jiantai precious plastic extrusion machine address some of these challenges through innovative features and robust designs tailored for diverse recycling needs.

Incorporating Sustainability: The Role of Recycled Plastic Extruder in Green Manufacturing

Using waste plastic extruders significantly contributes to sustainable and circular manufacturing practices. These machines give new life to discarded plastics by transforming them into reusable materials, effectively closing the loop in the recycling process.

Closed-Loop Recycling Systems

Closed-loop recycling systems are integral to sustainable manufacturing. Here’s how waste plastic extrusion machines play a pivotal role:

- Reduction of Raw Material Dependency: By converting waste plastics into new products, there is less need for virgin plastic materials. This reduces the environmental strain caused by plastic production from raw petrochemicals.

- Energy Efficiency: Jiantai’s newest recycled plastic extruder boasts a reduction in power consumption by up to 30%. This not only lowers operational costs but also minimizes the carbon footprint associated with the recycling process.

- Waste Minimization: Efficient extrusion ensures that almost all incoming plastic waste is repurposed, drastically cutting down on landfill contributions.

Contribution to Circular Economy

Recycled plastic extruders support the principles of a circular economy by ensuring materials are kept in use for as long as possible. Key benefits include:

- Product Lifecycle Extension: Products made from recycled plastics can be reprocessed multiple times, extending their lifecycle and reducing overall waste.

- Versatile Applications: From pipes and sheets to profiles, recycled plastics can be molded into various useful products, showcasing versatility and adaptability in different industries.

Environmental Impact

Waste plastic extruders play a critical role in mitigating environmental impact through:

- Reduced Greenhouse Gas Emissions: Lower energy requirements and decreased reliance on virgin materials result in reduced greenhouse gas emissions.

- Lower Pollution Levels: By reprocessing waste plastics, these machines help decrease pollution levels associated with plastic disposal and incineration.

Example in Action

Jiantai’s latest model exemplifies these sustainability benefits. Its advanced screw design, derived from military forging technology, ensures high efficiency and durability, making it an ideal choice for businesses aiming to enhance their green manufacturing practices.

Embracing recycled plastic extrusion technology is essential for forward-thinking manufacturers committed to sustainability. As advancements continue, the integration of such machines will become increasingly vital for achieving environmental goals.

The Future Outlook for Recycled Plastic Extruder Technology

The field of recycled plastic extrusion is poised for significant growth and transformation. One area with immense potential is the development of new resin recipes. These innovative mixtures can vastly improve the quality of recycled plastic products, making them more durable and versatile. By utilizing specific combinations of resins, manufacturers can now create materials that are not only on par with new ones but also more environmentally friendly.

Investing in advanced extrusion technology is crucial to unlocking this potential. For instance, Jiantai’s latest model has revolutionized the industry by reducing power consumption by up to 30%. This efficiency translates into faster production and lower costs for recycled plastic products, making them more accessible to consumers.

However, challenges still persist in this domain. Recycling plastics that have been contaminated or mixed together remains a complex task. It is imperative that we continue to explore novel methods for better sorting and cleaning techniques to maximize their reuse potential.

Moreover, the integration of artificial intelligence (AI) and automation has introduced remarkable possibilities. Computers and robots are now assisting in the manufacturing process, learning from their experiences to continually enhance performance. These intelligent machines identify and rectify issues promptly, resulting in smoother operations and reduced waste.

Key Advancements to Watch:

- Innovative Resin Recipes: Development of specialized formulations for enhanced material properties.

- Energy-Efficient Machines: Adoption of technologies that reduce energy consumption significantly.

- AI Integration: Use of artificial intelligence to streamline operations and improve product quality.

- Improved Recycling Techniques: Advanced methods for sorting and processing mixed plastics.

These advancements hold the potential to elevate recycled plastic extrusion into a cornerstone of sustainable manufacturing practices. With a combination of technological innovations and a growing demand for environmentally responsible solutions, the future of this industry looks promising.

Conclusion

The Jiantai Newest Recycled Plastic Extruder stands out for its significant advantages, including up to 30% reduction in power consumption and the adoption of military forging technology for its screw. These features not only enhance operational efficiency but also contribute to sustainable manufacturing practices by reducing energy use.

Reducing plastic waste is crucial in our fight against environmental degradation. Utilizing a high-quality, efficient recycled plastic extruder like Jiantai’s latest model empowers manufacturers to play a pivotal role in this effort.

Investing in state-of-the-art recycled plastic extrusion machines ensures that businesses stay ahead in an industry increasingly focused on sustainability. By adopting advanced technologies, manufacturers can minimize their environmental impact while maintaining competitiveness.

Take action today:

- Invest in the Jiantai Newest Recycled Plastic Extruder.

- Contribute to reducing plastic waste.

- Embrace sustainable and efficient manufacturing practices.

FAQs (Frequently Asked Questions)

What is the role of the Jiantai Newest Recycled Plastic Extruder in plastic recycling?

The Jiantai Newest Recycled Plastic Extruder plays a crucial role in the plastic recycling process by efficiently converting recycled plastic materials into useful products, thereby reducing waste and promoting environmental sustainability.

What are the key steps involved in recycled plastic extrusion?

Recycled plastic extrusion involves processes such as feeding, melting, mixing, conveying, and forming the plastic material into the desired shape or product. Using an efficient and high-quality extruder machine is essential for achieving better results in the recycling process.

What types of plastic products can be manufactured using recycled plastic extrusion?

Recycled plastic extrusion can be used to manufacture a wide range of products including pipes, sheets, profiles, and more. This versatility makes it a valuable technology for various industries.

What are some of the advantages and challenges associated with recycled plastic extrusion?

Recycled plastic extrusion offers environmental benefits and cost advantages by reducing the need for new raw materials and minimizing waste. However, challenges such as moisture control issues and difficulties in recycling certain types of plastics need to be addressed for optimal results.

How do recycled plastic extruders contribute to sustainable manufacturing practices?

Recycled plastic extruders play a vital role in sustainable manufacturing by enabling closed-loop recycling systems, which promote circularity and minimize environmental impact. This contributes to a more sustainable and eco-friendly approach to production.

What is the future outlook for recycled plastic extrusion technology?

The future of recycled plastic extrusion technology looks promising with potential advancements in resin formulations and production processes. Continued investment in this technology is crucial to overcome existing challenges and make it more economically viable for businesses.

How can manufacturers contribute to plastic waste reduction efforts?

Manufacturers can contribute to plastic waste reduction efforts by investing in state-of-the-art recycled plastic extrusion machines like the Jiantai model. By adopting sustainable manufacturing practices, they can minimize their environmental impact while staying ahead in the industry.

Antecs –

Very good plastic extrusion machine