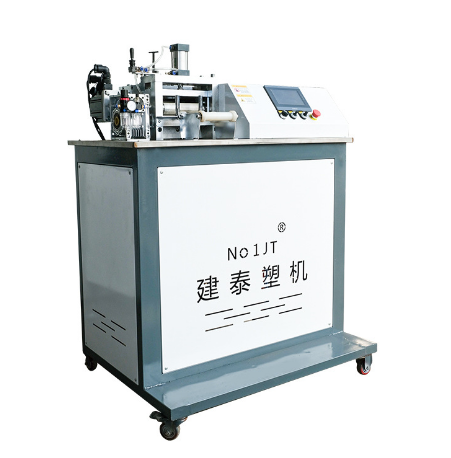

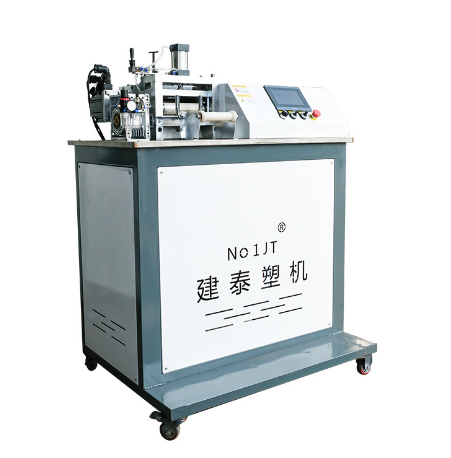

In the world of manufacturing, sustainability and efficiency are key drivers of innovation. The PVC Keychain Special Plastic Granule Regeneration Machine is a groundbreaking solution designed to meet the growing demand for eco-friendly production processes. This advanced machine transforms waste PVC material into high-quality plastic granules, which can be reused in the production of keychains and other PVC products. By integrating this machine into your manufacturing line, you can significantly reduce waste, lower production costs, and contribute to a more sustainable environment.

Key Features

- High Efficiency: The machine is engineered for maximum efficiency, capable of processing large volumes of PVC waste in a short amount of time. This ensures a continuous supply of regenerated granules, keeping your production line running smoothly.

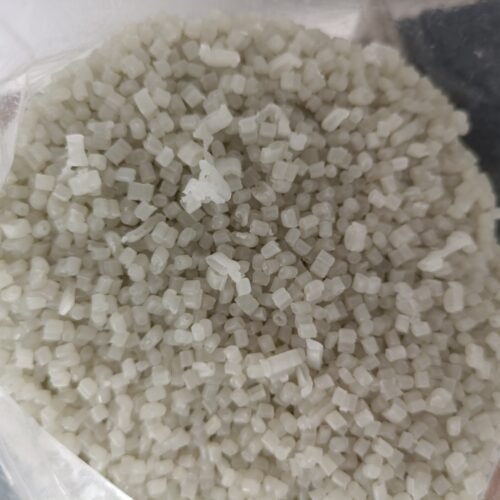

- Advanced Regeneration Technology: Utilizing cutting-edge technology, the machine converts waste PVC into high-quality granules. The regeneration process maintains the integrity and properties of the original material, ensuring that the granules are suitable for a wide range of applications.

- Energy Saving: Designed with energy efficiency in mind, the machine consumes less power compared to traditional recycling equipment. This not only reduces operational costs but also minimizes the carbon footprint of your manufacturing process.

- User-Friendly Interface: The machine is equipped with an intuitive control panel, making it easy to operate. Real-time monitoring and automated adjustments ensure optimal performance with minimal human intervention.

- Durable Construction: Built with high-grade materials, the machine is designed to withstand the rigors of continuous operation. Its robust construction ensures long-term reliability and minimal maintenance requirements.

Benefits

- Cost Reduction: By recycling waste PVC into reusable granules, manufacturers can significantly reduce the cost of raw materials. This leads to lower production costs and higher profit margins.

- Environmental Sustainability: The machine promotes eco-friendly practices by reducing the amount of PVC waste that ends up in landfills. This contributes to a cleaner environment and supports sustainable manufacturing initiatives.

- Quality Assurance: The regenerated granules produced by the machine meet high-quality standards, ensuring that the final products are durable and reliable. This consistency in quality helps maintain customer satisfaction and brand reputation.

- Versatility: The machine can process a variety of PVC waste types, making it a versatile addition to any manufacturing facility. Whether you produce keychains, pipes, or other PVC products, this machine can handle your recycling needs.

Applications

The PVC Keychain Special Plastic Granule Regeneration Machine is ideal for manufacturers in various industries, including:

- Keychain Production: Recycle waste from keychain manufacturing to produce new, high-quality keychains.

- PVC Pipe Manufacturing: Reprocess waste PVC pipes into granules for new pipe production.

- PVC Sheet and Film Production: Convert waste sheets and films into reusable granules.

- Automotive Industry: Recycle PVC parts and components used in automotive applications.

Conclusion

The PVC Keychain Special Plastic Granule Regeneration Machine represents a significant advancement in recycling technology. By integrating this machine into your production process, you can achieve substantial cost savings, enhance your sustainability efforts, and produce high-quality products consistently. Embrace the future of manufacturing with this innovative solution and take a step towards a more sustainable and profitable operation.

Citey –

We buy our PVC raw material from JianTai and it’s really good!