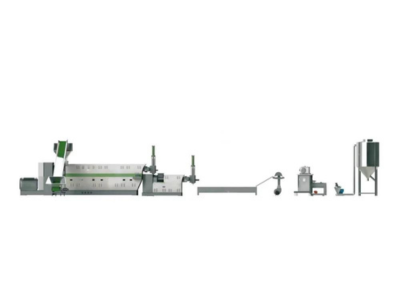

JT-SJP Series Plastic Pelletizer: A Revolution in Plastic Processing

Our JT-SJP series plastic pelletizers offer a versatile and reliable solution for converting plastics into uniform pellets. Here’s a closer look at our model range and their specifications:

| Model | L/D Ratio | Output (kg/h) | Screw Speed (rpm) | Power (kW) | Center Height (mm) |

|---|---|---|---|---|---|

| JT-45 | 28:1 | 25-30 | 10-120 | 7.5 | 650 |

| JT-65 | 28:1 | 55-70 | 10-120 | 11 | 650 |

| JT-80 | 28:1 | 100-120 | 10-120 | 18.5 | 700 |

| JT-90 | 28:1 | 120-140 | 10-120 | 22 | 730 |

| JT-100 | 28:1 | 140-170 | 10-120 | 30 | 750 |

| JT-110 | 28:1 | 180-220 | 10-120 | 37 | 750 |

| JT-120 | 28:1 | 220-260 | 10-120 | 45 | 750 |

| JT-130 | 28:1 | 270-330 | 10-120 | 55 | 800 |

| JT-140 | 28:1 | 350-420 | 10-120 | 75 | 800 |

| JT-150 | 28:1 | 450-550 | 10-120 | 90 | 800 |

| JT-160 | 28:1 | 550-650 | 10-120 | 110 | 850 |

| JT-180 | 28:1 | 800-950 | 10-120 | 150 | 900 |

What is a PET plastic recycling machine?

A PET plastic recycling machine is specialized equipment designed to recycle PET (Polyethylene Terephthalate) plastics, commonly used in products like water and soda bottles. The machine performs several key functions:

- Crushing and Shredding: Breaks down PET waste into smaller flakes.

- Washing and Cleaning: Removes contaminants such as labels and residues.

- Separation: Differentiates PET from other materials like caps and rings.

- Drying: Eliminates moisture from the cleaned PET flakes.

- Extrusion and Pelletizing: Melts the flakes and extrudes them into strands, which are then cooled and cut into uniform pellets.

Advantages of JianTai’s PET Plastic Recycling Machine Line

High Efficiency

Our machines are designed to maximize output while minimizing energy consumption, ensuring efficient recycling processes.

Advanced Technology

Equipped with the latest technology, including PLC touchscreen controls, for precise and easy operation.

Customizable Configurations

Tailored solutions to meet specific customer needs, from machine size to production capacity and control systems.

Robust Construction

Built with high-quality materials and military-grade components for durability and long-term reliability.

User-Friendly Design

Easy to operate and maintain, reducing downtime and increasing productivity.

Strong After-Sales Support

Comprehensive services including installation, training, and maintenance, along with a one-year warranty on core components.

JianTai PET Plastic Recycling Machine

Semi-Automatic PET Plastic Recycling Machine

Semi-Automatic Regeneration Machine Components

| Plastic Scrap Cleaning Equipment | × |

| Plastic Feeding Machine | × |

| Plastic Extruder | √ |

| Plastic Extrusion Abrasives | √ |

| Plastic Cooling Unit | √ |

| Plastic Cutting Machine | √ |

| Plastic Pellet Loading Equipment | × |

| Production Capacity | 100KG/H-500KG/H |

Fully Automatic PET Plastic Recycling Machine

Fully automated regeneration machine components

| Plastic Scrap Cleaning Equipment | √ |

| Plastic Feeding Machine | √ |

| Plastic Extruder | √ |

| Plastic Extrusion Abrasives | √ |

| Plastic Cooling Unit | √ |

| Plastic Cutting Machine | √ |

| Plastic Pellet Loading Equipment | √ |

| Production Capacity | 200KG/H-1000KG/H |

JianTai PET Plastic Recycling Machine Details Exposed

Plastic Recycling Machine Screws

The screws and barrels of plastic recycling machines are crucial components that determine the efficiency and longevity of the machinery. JianTai, a renowned brand in the plastic machinery industry, manufactures these components with precision and high-quality materials.

Materials:

- Screw and Barrel Material: 38CrMoAlA

- Heat Treatment: Nitriding and Quenching

JianTai’s screws and barrels are produced in Zhoushan, a city known for its expertise in manufacturing high-performance machine parts. The use of 38CrMoAlA steel, treated with nitriding and quenching processes, ensures exceptional hardness, wear resistance, and durability, making these components ideal for high-demand plastic recycling applications.

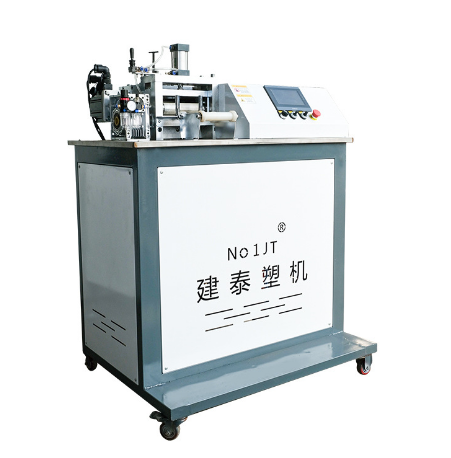

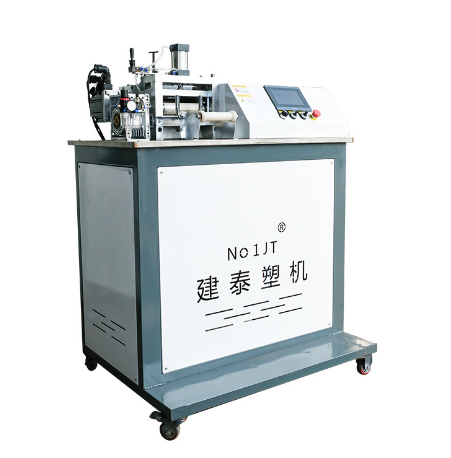

PLC Touch Screen Control System

The PLC touch screen control system is a state-of-the-art feature integrated into JianTai’s plastic recycling machines, enhancing user experience and operational efficiency.

Features:

- User-Friendly Interface: The touch screen provides an intuitive and interactive interface, making it easy for operators to monitor and control the machine.

- Precision Control: The PLC (Programmable Logic Controller) ensures precise control over the machine’s functions, allowing for fine-tuning of processes to achieve optimal performance.

- Real-Time Monitoring: Operators can view real-time data on machine performance, including temperature, pressure, and production metrics, directly on the screen.

- Automated Processes: The system allows for automation of various processes, reducing the need for manual intervention and minimizing the risk of human error.

- Diagnostic Capabilities: Built-in diagnostics help quickly identify and troubleshoot issues, ensuring minimal downtime and efficient maintenance.

Questions About PET Plastic Recycling Machines

What are the benefits of using a PET plastic recycling machine?

Resource Efficiency: Conserves raw materials by reusing recycled plastic.

Cost Savings: Lowers material costs for manufacturers using recycled PET.

Energy Efficiency: Generally consumes less energy compared to producing new PET from raw materials.

Sustainability: Supports sustainable practices and circular economy initiatives.

What features should I look for in a PET plastic recycling machine?

Efficiency: Look for high throughput and low energy consumption.

Quality of Output: Ensure the machine produces high-quality recycled PET flakes or pellets.

Durability: Machines made with high-quality materials for long-term use.

Ease of Operation: User-friendly controls and minimal training requirements.

Maintenance Requirements: Low maintenance and easy access for repairs.

How much does a PET plastic recycling machine cost?

What maintenance is required for a PET plastic recycling machine?

Routine Inspections: Regularly check for wear and tear on components.

Cleaning: Keep the machine clean to prevent contamination and ensure smooth operation.

Lubrication: Lubricate moving parts as per the manufacturer’s recommendations.

Replacement of Worn Parts: Replace any worn or damaged parts promptly to avoid breakdowns.

Software Updates: If the machine includes automated systems, keep the software updated to benefit from the latest improvements and fixes.

Antecs –

Very good plastic extrusion machine