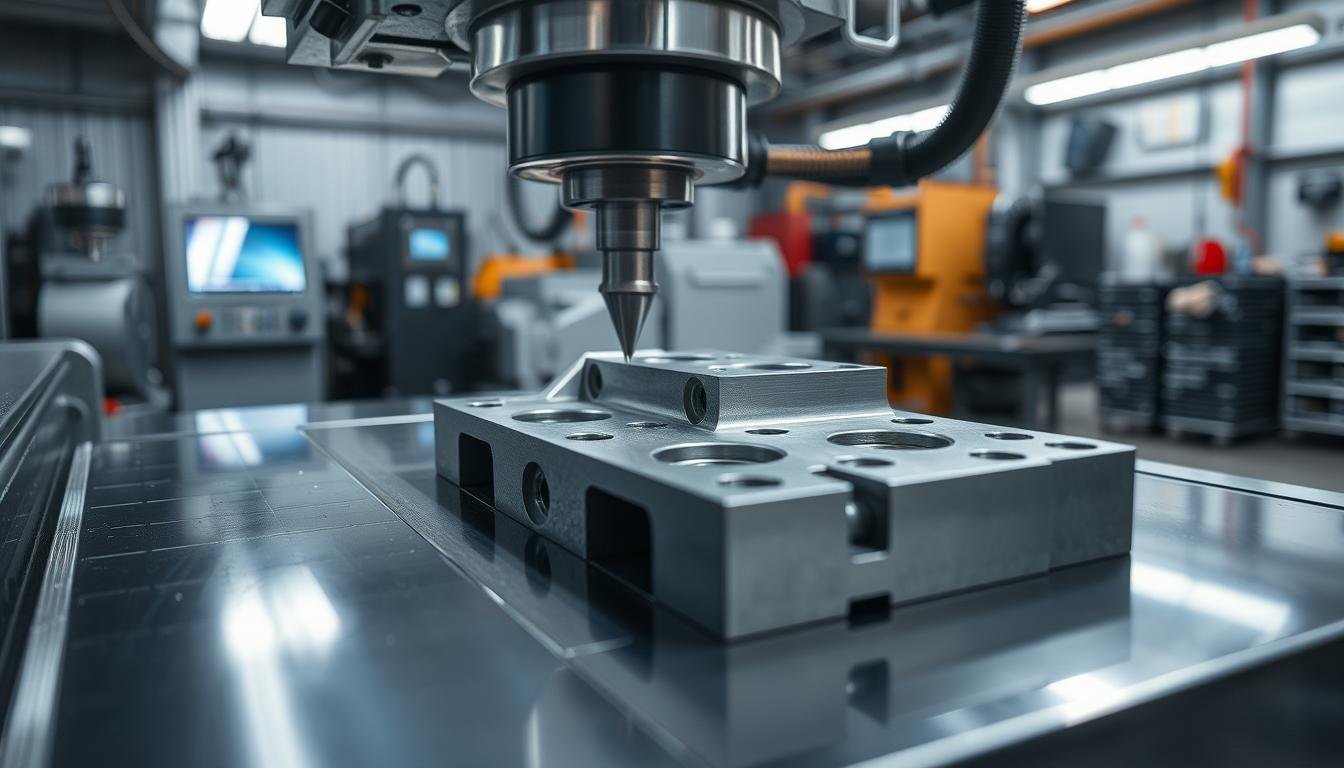

For over 40 years, The Federal Group USA has led the way in CNC Machining. We offer Precision Machining works to clients in many sectors. Thanks to computers, our Custom Machining Services are very accurate and high-quality.

Our equipment can handle big and complex tasks up to 84 inches by 50 inches. We have machines with 3, 4, and 5 axes. This allows us to meet the advanced needs of today.

Industries like aerospace and medical benefit a lot from our work. Our machines are so precise, they can work to +/- 0.01 mm. This precision helps us handle many materials, including titanium and zinc. Our 5-axis machines are also faster, improving efficiency.

We are very committed to quality. Our work is very accurate, to +/-0.002 in (0.0508 mm). We follow strict quality rules, including ISO 9001 and AS9100. Our technology can create specific shapes and finishes, matching each project’s needs perfectly. We have over 50 advanced CNC machines, ready for any task.

Key Takeaways

- Over 40 years of leading CNC precision machining for different industries.

- Up to 5-axis CNC milling machines for complex jobs.

- Our commitment to top-notch tolerances and custom solutions for all.

- 5-axis machines bring efficiency and save time.

- Following strict quality and international standards for all projects.

- We offer a wide range of custom options.

- Our team focuses on custom needs and customer satisfaction.

Understanding CNC Machining and Its Evolution

CNC milling and turning have changed a lot since they started. They began with manual methods that needed skilled workers. Now, we have moved to using advanced automated CNC machining. This change shows how we went from manual work to using computer control systems.

The Fundamentals of CNC Milling and Turning

CNC milling uses different cutting tools that move in complex ways. For example, there are 3-axis and even more complex 5-axis systems. On the other hand, CNC turning uses a single-point tool to shape rotating pieces. These methods are key in making precise parts for many fields, like aerospace and electronics.

Transition from Traditional to CNC Machining

Manufacturing was once all about manual work. But then, programmable machines changed everything. CNC machining brought faster production and more consistent quality. This evolution from simple machines to digital tech shows CNC’s growing role in making things.

The Role of Computer Numerical Control in Modern Machining

Computer numerical control, or CNC, is central to today’s machining. It automates tasks that need to be very accurate. CNC reads designs from CAD and CAM software and turns them into real parts. This process has made CNC essential for making high-quality items with little mistake.

Many industries now depend on CNC machinery. This technology boosts how much they can make and how good their products are. CNC is very important in engineering and making things today.

The Advantages of Precision CNC Machining

In the world of making things, CNC prototyping is a big deal. It has hugely improved manufacturing efficiency and made full-scale production smoother. By using precision CNC machining, companies see better product quality and save on costs too.

Precision CNC machining changes many parts of making things:

- High precision is key in areas like aerospace and defense where tiny details matter a lot.

- CNC machines work all day and night. This boosts how much they can make while cutting down on work needed by people.

- This technology lets producers change their output fast, making handling different orders easier.

- Once CNC machines are set up, they work quickly. This speeds up going from a design to a finished product.

- They can also switch tools on their own during milling. This lets them make complex shapes, improving what they can make.

CNC machining works with many materials, like metals, composites, plastics, and foams. This makes CNC machines very important in today’s making places. They meet a lot of different needs across industries.

CNC machines work on their own, cutting down mistakes. This steady quality is key for keeping things the same over many products. Even with this automation, CNC machinery needs little upkeep. This means it costs less over time because it doesn’t break down as much.

This way of working is not just a step forward in tech. It’s essential for businesses. It brings many benefits, from safer workplaces to consistent products and quicker making times.

As companies look for ways to spend less and do more, precision CNC machining shines. It answers these challenges well, showing its key role in staying ahead in business.

CNC Machining Applications Across Industries

CNC machining is vital in many sectors. It uses advanced tech in aerospace, healthcare, and automotive for creating complex parts. These industries use this tech to keep quality and efficiency up.

Aerospace: The High Stakes of Precision

In aerospace, precision is everything. CNC is key for making precise plane parts, like airfoils and engine components. The need for accuracy down to 4µm makes CNC essential for airplane safety and function.

Healthcare: Innovations in Medical Equipment Manufacturing

The healthcare industry sees big benefits from CNC in making devices. It’s great for custom medical equipment and sticking to FDA rules. CNC’s precision is vital in making healthcare manufacturing better.

Automotive: Prototyping and Production Prowess

Automotive CNC machining speeds up the making of car prototypes. It’s critical in the auto industry for refining designs. CNC helps make sure parts like gearboxes and axles are perfect before full production. This ensures car parts are top quality and interchangeable.

| Industry | Components | Importance of CNC Machining |

|---|---|---|

| Aerospace | Airfoils, Engine Parts, Landing Gear | Essential for achieving the required precision and safety standards |

| Healthcare | Orthopedic Implants, Surgical Tools | Crucial for manufacturing personalized and high-precision medical devices |

| Automotive | Gearboxes, Axles, Car Bodies | Key to refining product designs and ensuring perfect component compatibility before production |

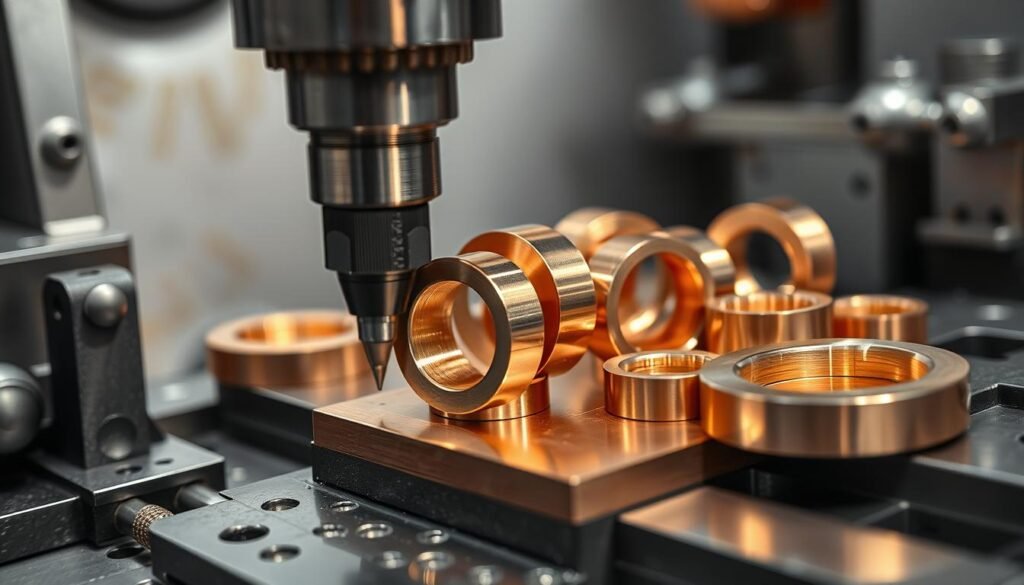

Materials Revolutionized by CNC Machining

CNC machining has greatly changed how we work with materials in manufacturing. It makes specific CNC materials much easier to use thanks to its precision and automation.

Machining copper has been revolutionized by CNC. This technology allows for complex shapes with less waste. Copper is ideal for electrical parts because it conducts heat and electricity well. Yet, it’s soft and hard to work with. CNC machines make it easier, improving how fast and accurately we can make complex parts.

CNC machining also shines with titanium milling. Titanium is strong and resists corrosion but is hard to shape using old methods. CNC machining makes working with it precise, which is key for aerospace and medical devices. These industries need titanium for its lightweight but durable features.

- CNC machining offers parts with tight tolerances, crucial for high-accuracy needs.

- It works on its own, cutting down production time and upping efficiency.

- Its exceptional repeatability means every part is of uniform quality.

- It can handle many materials, perfect for making complex parts.

Thanks to CNC machines, making custom CNC components is now faster, with fewer mistakes and lower costs. This boosts how well operations run and leads to more innovation across fields. It makes for more advanced product designs and faster market launches.

Pairing CNC machining with AI and machine learning will likely make production even better. This combo is expected to lower downtime, improve maintenance before things break, and use materials more efficiently. All these points highlight the importance of CNC in today’s manufacturing wonders.

Maximizing Precision with 3-Axis CNC Milling Machines

3-axis CNC mills are crucial in precision machining across various industries. They’re fundamental due to their strong abilities. Despite newer, complex machines, 3-axis mills play a key role in precise vertical milling.

3-axis CNC mills are valued for their simplicity and efficiency. They make vertical milling both efficient and cost-effective. This efficiency is vital in woodworking, prototyping, and basic metalworking, where simple shapes are often needed.

The Basics of 3-Axis Milling Operations

3-axis CNC mills move along three axes: X, Y, and Z. This movement allows for cutting, drilling, and slotting in straightforward designs. Though their range is less than multi-axis machines, 3-axis mills excel at essential manufacturing tasks.

Comparing 3-Axis to Advanced CNC Milling Options

Comparing 3-axis to 4-axis and 5-axis machines shows a clear evolution. 3-axis machines offer basic services, while 4 and 5-axis provide advanced geometry handling. This allows for more complex designs and fine details without multiple setups.

4-axis machines add rotation around the X-axis, increasing their ability to make intricate parts. These are used in industries like aerospace, medical, and automotive. 5-axis machines can move in five directions at once. They offer unmatched precision, critical in creating complex aerospace parts and detailed automotive components.

In conclusion, choosing between 3-axis, 4-axis, and 5-axis CNC mills depends on production needs. Whether you need cost efficiency with 3-axis or intricate precision with 4 and 5-axis, it’s crucial to match machine capabilities to your industry requirements for the best output.

Enhanced Capabilities with 4-Axis CNC Milling

4-axis CNC machining has changed the game by adding a rotary axis called the A-axis. This lets us do rotary axis milling. This means we can make complex parts and designs more accurately. These machines are perfect for jobs needing high detail and accuracy.

Aerospace, automotive, and electronics industries benefit greatly from 4-axis CNC machines. They’re crucial for making parts like turbines for aerospace, engine parts for cars, and circuit boards for electronics. These industries need the best precision. 4-axis machines deliver this by allowing complex milling angles and efficient production.

| Industry | Applications of 4-Axis CNC Machining | Benefits |

|---|---|---|

| Aerospace | Turbine components, Airframe parts | Precision, Speed |

| Automotive | Engine components, Body parts | Efficiency, Precision |

| Electronics | Circuit boards, Casings | High precision, Detailed accuracy |

| Oil and Gas | Durable machine components | Durability, Extreme condition performance |

4-axis CNC machining offers many benefits like better efficiency and handling complex shapes. But they are costly and need skilled operators. The machines also require advanced software for programming, which might be tough for some manufacturers at first.

The 4-axis CNC machining is very versatile. It improves function and use in heavy-duty sectors. It is also making its way into medical equipment, architecture, and art. This flexibility makes it an essential tool for different industries looking to innovate their manufacturing.

The Pinnacle of Machining Precision

5-axis CNC precision takes the lead in modern manufacturing tech. It meets the growing needs for making complex parts in various industries.

The unique power of 5-axis CNC machining makes complex parts easy to create. It’s key for sectors like aerospace and healthcare where every detail matters.

5-Axis CNC Machining: Achieving Complex Geometries

With two extra rotational axes, 5-axis CNC machines craft detailed components. They work well with materials like titanium, allowing for advanced milling.

The Superior Precision and Efficiency of 5-Axis Machining

5-axis CNC machining excels in making refined parts quickly. This boosts competition and meets market demands fast. It wastes less material and energy, which is good for our planet.

Through 5-axis CNC precision and tech, we push manufacturing to new heights. It lets us take on complex projects, opening doors to new product innovations.

State-of-the-Art Equipment at The Federal Group USA

The Federal Group USA takes pride in its high-quality craftsmanship. This is shown by our ISO 9001 certified management system. We have advanced milling equipment across our facilities. Our experts have years of experience, making us leaders in machining at TFG USA.

Advanced Precision CNC Milling Machines

We have many screw machines, from quick single-spindle ones to strong multi-spindle types. They handle intricate tasks smoothly. Our CNC mills shape parts with extreme accuracy, up to +/- 0.0002 inches. Our advanced 5-axis machines have pallet technology. We also use versatile 3-axis & 4-axis platforms. This tech boosts efficiency and quality in various industries like automotive and aerospace.

Adapting to High and Low Capacity Production Runs

The Federal Group USA adjusts to changing market demands. We can do big or small production volumes. Our supply chain is reliable, thanks to scalable systems. These systems quickly adapt while keeping our quality high. Our multi-axis lathes work around the clock. And our team always provides great customer service. We meet the needs in defense, medical devices, and more with unmatched precision machining.

FAQ

What are Precision CNC Machining Services?

Precision CNC Machining Services are modern ways to make parts accurately with computers. Techniques like milling and turning are used. They create specific components needed in various fields.

How has CNC Machining evolved from Traditional Machining?

CNC machining moved us from manual to automated work. Now, software controls the process. This makes making things faster, more consistent, and more complex.

What is the role of Computer Numerical Control in Machining?

Computer Numerical Control, or CNC, is critical in today’s machining. It directs machines based on digital designs. CNC achieves great precision and can make complex parts that manual methods cannot.

What are the advantages of utilizing CNC Prototyping and Full-Scale Production?

CNC prototyping and production bring big benefits. They make making things quicker and less costly. This means companies can quickly meet the demands of the market.

In which industries is CNC Machining particularly critical?

CNC Machining is key in aerospace, healthcare, and automotive fields. It makes high-precision parts, advanced medical devices, and complex car components.

How has CNC Machining revolutionized the use of materials?

CNC machining lets industries use many types of materials, from metals to composites. This versatility allows for custom parts to meet specific industry needs.

What is the difference between 3-Axis and 4-Axis or 5-Axis CNC Milling?

3-Axis CNC milling works on three axes, good for simple tasks. But 4-Axis and 5-Axis milling add rotation. This means they can make more complex shapes faster.

How does 5-Axis CNC Machining enhance manufacturing precision?

5-Axis CNC Machining works on five axes at once. This helps make detailed designs and unique finishes. It’s great for making very complex parts with high accuracy.

What capabilities does The Federal Group USA offer with its CNC Machining Services?

The Federal Group USA has advanced CNC milling machines. They work on 3, 4, and 5 axes. They’re set up for both big and small orders, ensuring fast and smooth production.