Understanding the Market for Plastic Recycling

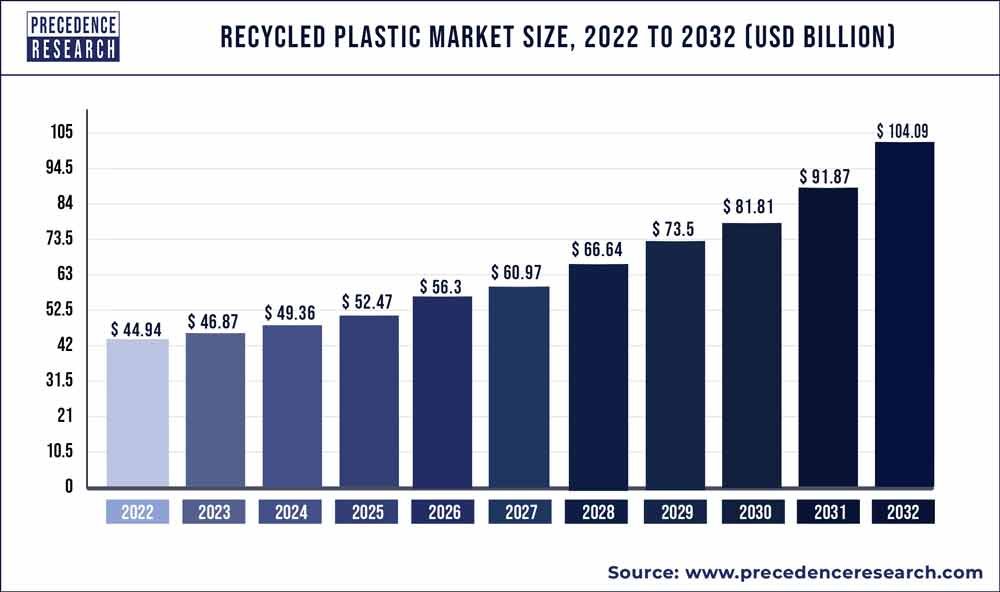

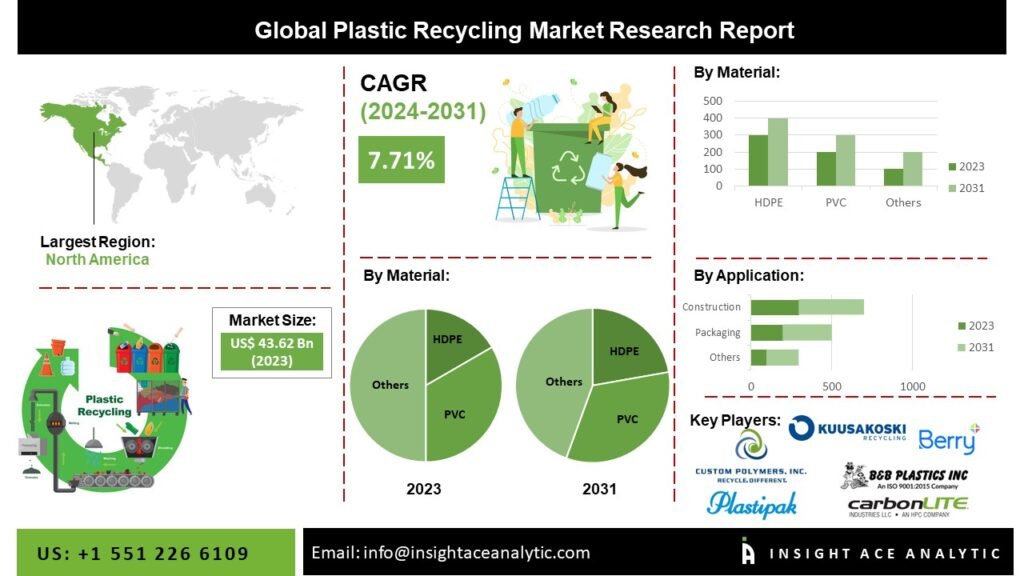

Global Demand for Recycled Plastics

The world needs more recycled plastics every day. Countries want to reduce waste and protect the environment. Also, laws and rules help push companies to recycle. Using recycled plastics can save money too, which is good for businesses.

Key Industries Utilizing Recycled Plastics

Many industries use recycled plastics. For example, the packaging industry uses recycled plastics for making bottles and containers. The automotive industry uses them for car parts. Also, the construction industry uses recycled plastics in building materials.

Types of Profitable Plastic Recycling Machines

Plastic Shredders

Plastic shredders are very important. They cut plastic waste into small pieces. When buying a shredder, look for strong blades and good safety features. For example, the “EcoShred 2000” is a great model because it works fast and is safe.

Plastic Granulators

Granulators are different from shredders. They turn small plastic pieces into even smaller granules. These granules are easier to melt and reuse. Good granulators are powerful and quiet. The “Granulator Pro Max” is popular because it is efficient and doesn’t make much noise.

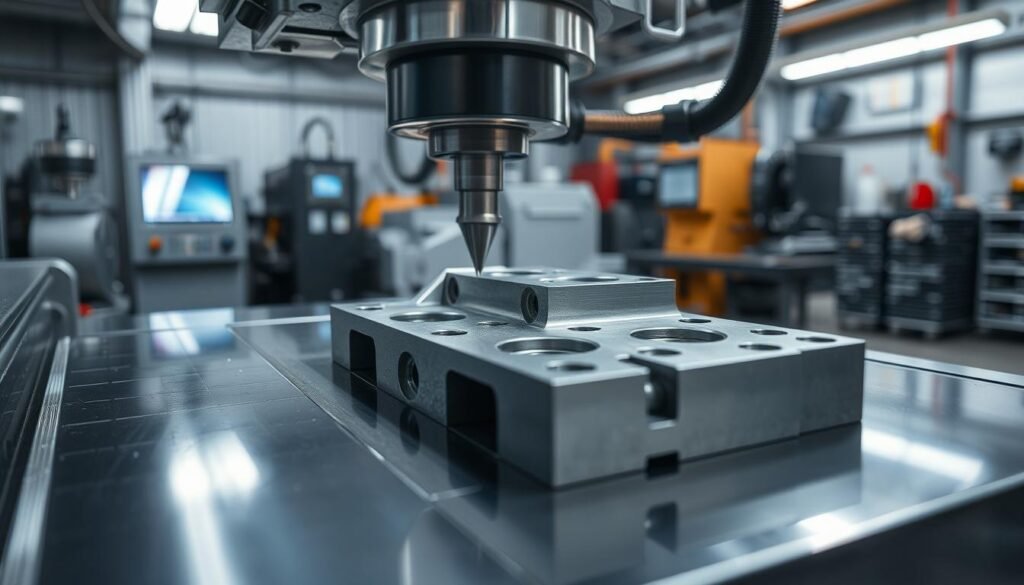

Extrusion Machines

Extrusion machines change plastic waste into pellets. There are two types: single-screw and twin-screw machines. Single-screw machines are simpler, while twin-screw machines are faster. The “Twin-Screw Extruder 3000” is a high-profit model because it works quickly and reliably.

Washing Lines

Washing lines clean plastic waste. They have many parts like washers, rinsers, and dryers. Clean plastic is worth more money. The “CleanLine 500” is a top model because it saves water and energy while cleaning well.

Factors Influencing the Profitability of Recycling Machines

Quality and Efficiency of the Machine

Good machines make more money. High-quality machines work better and last longer. Efficient machines save time and energy. For example, the “Efficient Recycler 1000” is known for its reliability and speed.

Maintenance and Operating Costs

All machines need care. Regular maintenance keeps them running well. Simple maintenance tasks, like cleaning filters, can save money. When you buy a machine, think about the total cost, including upkeep.

Market Prices for Recycled Plastics

The price of recycled plastics can go up and down. Right now, clear plastic bottles sell for a high price. Keep an eye on market trends to know when to sell. This way, you can get the best price for your recycled plastic.

Maximizing Profits with Plastic Recycling

Strategic Sourcing of Plastic Waste

To make money, you need lots of plastic waste. Therefore, find good sources, like local businesses and recycling centers. By building strong partnerships, you can ensure you always have enough plastic to recycle. Consequently, these partnerships help maintain a steady supply of plastic waste for your recycling efforts.

Optimizing the Recycling Process

Make your recycling process as smooth as possible. Therefore, use technology to track and improve your operations. The better you recycle, the more money you make. Additionally, best practices, like sorting plastic well, help a lot. Consequently, by following these practices, you can enhance efficiency and profitability.

Diversifying Product Offerings

Don’t just sell one type of recycled plastic. Offer many types to attract more buyers. You can also make value-added products, like recycled plastic bricks or furniture. Look for new markets to sell your products.

Case Studies of Successful Plastic Recycling Businesses

Small-Scale Recycling Plant

GreenEarth Recycling is a small plant in Ohio. They use machines called the “EcoShred 2000” and the “CleanLine 500”. Because of this, they make $50,000 a year by selling clean, shredded plastic to local companies. Their success comes from careful sourcing and good machine maintenance. As a result, these practices help them consistently produce high-quality recycled plastic.

Large-Scale Industrial Recycling Facility

BigRecycling Co. is a large facility in Texas. They use many machines, including the “Twin-Screw Extruder 3000”. As a result, they make over $1 million a year by selling high-quality plastic pellets to big manufacturers. Their key to success is investing in top machines and, furthermore, optimizing their recycling process. Consequently, these efforts help them achieve great results.