How much plastic trash is on the oceans?

It is estimated that between 75 and 199 million tons of plastic trash currently exists in our oceans, with an additional 33 billion pounds of plastic entering the marine environment each year. This steady stream of plastic production is simply too much for the existing waste management and recycling infrastructure to handle.

From microplastics in the food chain to plastic water bottles floating on the surface, plastic pollution permeates every inch of the ocean. There is no more famous example of this than the Great Pacific Garbage Patch. This monolith of ocean pollution is made up of all kinds of marine debris, contains 1.8 trillion pieces of plastic, and covers an area twice the size of Texas.

How much plastic waste is on land?

New research has found that a staggering 220 million tonnes of plastic waste is set to be generated in 2024, marking a 7.11% increase since 2021.

The latest study, by charity EA Earth Action, and released last week, revealed that more than a third of plastic waste will be improperly handled at the end of its lifecycle. This equates to 68.6 million tonnes of plastic, translating to an average of 28kg of plastic waste per person worldwide.

The report also announced this year’s Plastic Overshoot Day, on 5 September 2024, which marks the moment when the amount of plastic waste generated surpasses the world’s ability to manage it. Each country has its own Plastic Overshoot Day, determined by its plastic waste generation and management capacity.

The EA Earth Action report identifies 117 days of plastic overshoot, meaning the plastic waste produced during these days ‘will not be well managed’. It says that only 12 countries are responsible for 60% of the global mismanaged plastic waste. Among them, the top five are China, the US, India, Brazil and Mexico.

How to properly address the plastic waste problem? Oceans and land

In the face of so much ocean plastic waste, we should properly guide all people to reduce the amount of garbage we put out and the proper use of plastic.

If the sea takes on burdens it shouldn’t have to, I objectively think the sea will slowly die out, thus affecting the whole world. Just like India is facing high temperatures lately, do you guys think its right to have high temperatures?

No, I don’t think so, when you go to India and you see their mother river (Ganges) you’ll see it’s so dirty, it’s taking on burdens it shouldn’t have to take on, in the early days of old it (Ganges) it was supposed to be clean because it (Ganges) has its source in the southern foothills of the Himalayas in China, and in the face of the weighty rule of preserving the environment, I think China’s done the right thing on that front, and it’s accomplished the greening of the deserts, and that’s really That’s really important.

China is changing its own environmental problems to preserve the best environment for future generations to come.

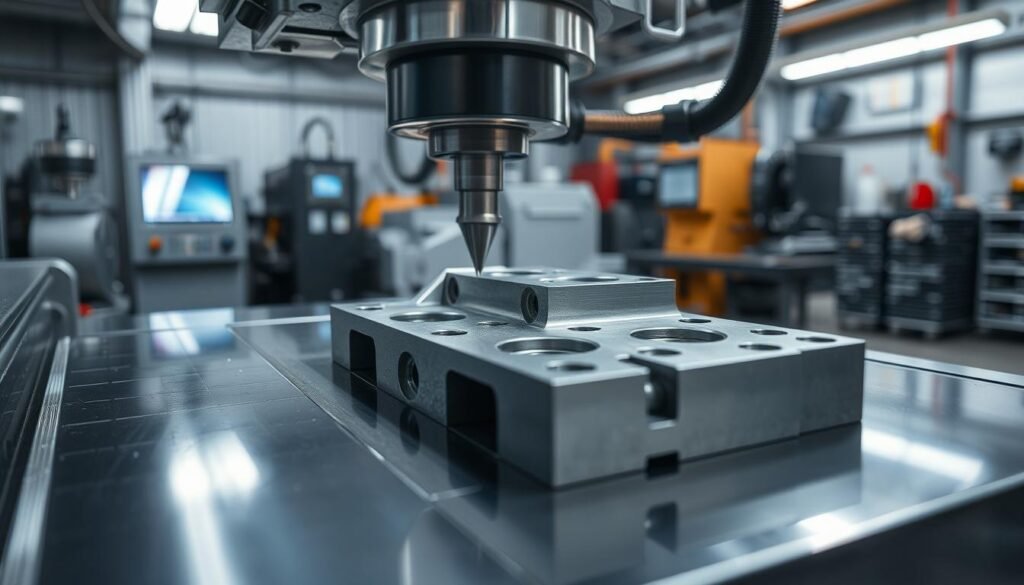

The environmental problem of plastic waste can be solved by plastic recycling machines

We have to first understand the plastic recycling machine what it is? Why plastic recycling machine can solve the plastic waste environment? This is a good question. Early we face plastic are through the oil to transform into plastic this material, but plastic its characteristics are very good, it can be re-broken and then through the high temperature softening, and finally become a new plastic.

Then we choose a plastic recycling machine, we should not think that this machine is very expensive or have any cognitive bias, we need to know that a small plastic recycling machine, it can solve all the plastic waste in your local area.

It is because there is a constant stream of plastic waste that you can make more plastic pellets that can be reused with a plastic recycling machine, so let’s understand, if you solve the local plastic waste problem and gain profit from it (which of course it will be 100% gained because of the recycled plastics that you can sell), wouldn’t you think that you should go ahead and do this? All things are gained before you start to move forward, and I think you can move forward with this issue from a profit standpoint and properly solve your local plastic waste problem.

Plastic recycling machine to make new plastic pellets principle

Plastic recycling machines transform waste plastic into new plastic pellets through a series of mechanical and thermal processes. Here are the main steps and principles involved in plastic recycling:

1. Collection and Sorting

- Collection: Waste plastic materials are collected from household, industrial, commercial, and other sources.

- Sorting: Plastics are sorted based on type (such as HDPE, LDPE, PET, PP, etc.) and color. Proper sorting is a crucial step because different types of plastics have different melting points and chemical properties.

2. Cleaning and Shredding

- Cleaning: Water and chemicals are used to remove dirt, grease, and labels from the surface of the plastic.

- Shredding: The cleaned plastic is put through a shredder to be broken down into small pieces or flakes. This step helps in the subsequent melting and plasticizing process.

3. Melting and Plasticizing

- Melting: The shredded plastic pieces are heated in a heating unit to their melting point, transforming them into a molten state. Each type of plastic has a different melting point, so appropriate temperature control is needed.

- Plasticizing: The molten plastic is pushed through an extruder where it is subjected to pressure and shear forces, gradually homogenizing and forming a continuous molten flow.

4. Filtering and Degassing

- Filtering: The molten plastic passes through metal filters to remove impurities like metal fragments and unmelted plastic pieces. This step ensures the purity of the recycled plastic pellets.

- Degassing: Vacuum systems or ventilation devices remove bubbles and volatile components from the plastic melt, preventing bubbles or defects during the molding process.

5. Pelletizing

- Extruding: The molten plastic is extruded into long strips or ribbons.

- Cooling: The extruded plastic strips are cooled in a water bath or by air cooling, hardening them for cutting.

- Pelletizing: The cooled plastic strips are cut into small pellets, commonly referred to as “recycled plastic pellets” or “plastic granules.”

6. Inspection and Packaging

- Inspection: The recycled pellets undergo quality checks to ensure they meet the specified size, purity, and melt index standards.

- Packaging: The compliant recycled plastic pellets are packaged into bags or boxes, ready for shipment or storage.

Machines and Equipment

Plastic recycling machines typically include the following major equipment:

- Shredder: For shredding waste plastic.

- Washing Machine: For cleaning plastic flakes.

- Extruder: For melting and extruding plastic.

- Cooling Equipment: For cooling extruded plastic.

- Pelletizer: For cutting plastic strips into pellets.

How to choose a quality plastic recycling machine?

We should choose a high-quality plastic recycling machine from a number of perspectives, first of all, this plastic recycling machine its core configuration (screw) how long the service life, and this plastic recycling machine can save you how much energy? Remember, do not ignore the issue of saving energy! Because it is also in disguise to protect the environment.

Recommended JianTai Plastic Recycling Machine

The JianTai plastic recycling machine is equipped with the latest servo motors, which can save up to 30% of energy consumption. What kind of concept is this? Let me give you an example, if your plastic recycling machine runs for a year and you deduct 30% from your electricity bill, you will be surprised to find that you can actually buy a new plastic recycling machine. This means you can expand your program.

The core configuration (screw) of the military forging technology, because JianTai Plastic Machinery Company retains the technology of the Chinese Arsenal, which makes it have the military forging technology, so that your machine greatly improves the service life.

PLC touch screen control system, originally we are using Siemens or other brands of knob control machine, but this it is easy to damage, once damaged it needs to go one by one to replace, that JianTai Plastic Machinery Company is now using PLC touch screen control system, so that you can greatly reduce the control system damage problems.And of course the more important point: it allows precise control of the plastic recycling machine to a state of zero error.

What is the price of JianTai plastic recycling machine?

If the budget is not enough, we recommend that you can use a used plastic recycling machine, which can ensure that your machine can operate normally on the premise, but also can get a certain amount of revenue. This will help you to have enough money to buy a brand new plastic recycling machine next time.

Our normal price for a brand new minimum plastic recycling machine is $9600, but of course it can be much cheaper if you choose used!

FQA

How much plastic trash is on the oceans,Reference content sources:https://www.rts.com/blog/plastic-pollution-in-the-ocean-facts-and-statistics/

How much plastic waste is on land,Reference content sources:https://www.foodbev.com/news/research-2024-sees-continued-increase-in-plastic-waste/