Plastic is everywhere in our world. It’s used to make so many things, from water bottles to car parts to toys. The problem is, a lot of plastic ends up as trash and can take hundreds of years to break down. This is bad for the environment.

The good news is that more and more plastic is getting recycled instead of thrown away. New inventions are making it easier than ever to recycle plastic. Let’s take a look at some of the latest, greatest recycling machines!

Why is Recycling Plastic Important?

Before we dive into the cool new recycling tech, let’s talk about why recycling plastic matters in the first place.

Plastic Waste is Piling Up

Did you know that humans have made over 8 billion tons of plastic since it was invented? That’s heavier than a billion elephants! A lot of that plastic gets tossed in the garbage. Plastic makes up a big chunk of what’s in our landfills.

Plastic Hurts Animals and the Environment

Plastic that ends up in nature causes big problems. Animals like sea turtles and birds can mistake small bits of plastic for food. Eating plastic makes them sick. Plastic can also break down into teeny tiny pieces called microplastics. These get into the soil and water.

Making New Plastic Uses Oil and Energy

To make plastic, we need to use oil, which is a nonrenewable resource. Making plastic also takes a lot of energy, which often comes from burning fossil fuels. This adds to greenhouse gas emissions that drive climate change.

Recycling Plastic Helps a Lot

When we recycle plastic instead of making new plastic, it uses less oil and energy. Recycling keeps plastic out of landfills and nature. But recycling can be tricky. Plastic has to be sorted, cleaned, and processed. That’s where new recycling inventions come in.

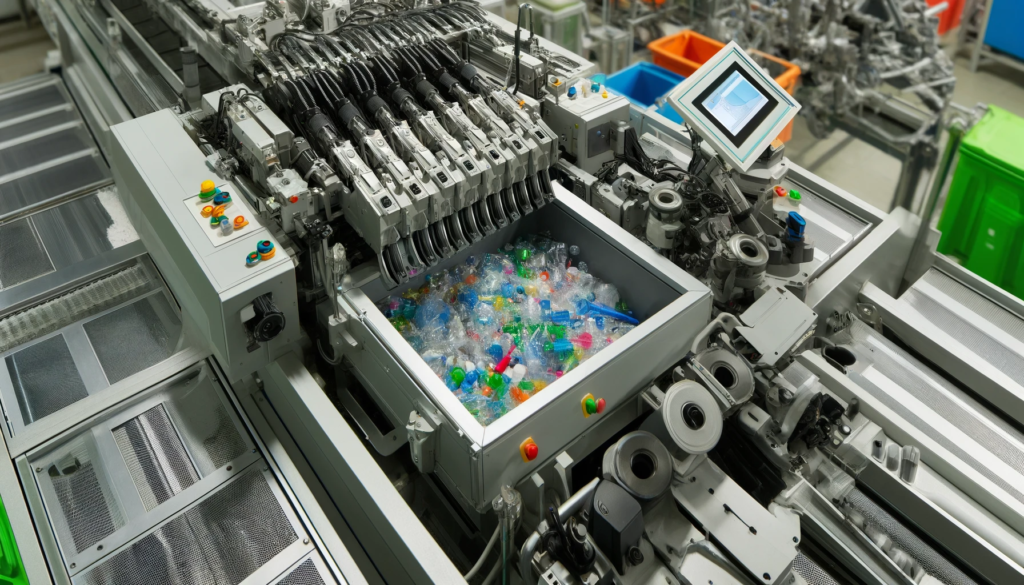

Sorting Plastic: Machines That Can Tell Types Apart

One of the biggest challenges in recycling plastic is sorting the different types. There are seven main types of plastic. Each type has to be recycled separately. In the past, a lot of the sorting was done by hand. It was slow and expensive. But now, smart sorting machines are taking over.

Infrared Plastic Sorters

Some of the most high-tech sorting machines use near infrared light (NIR) sensors. Here’s how it works:

- Plastic trash goes onto a conveyor belt

- It passes under super bright NIR lights

- Each type of plastic reflects the NIR light differently

- The machine reads the reflections to identify the plastic types

- Puffs of air shoot out to push each plastic type into separate bins

NIR sorters can process tons of plastic really fast, with up to 98% accuracy. Some well-known brands are the MSS FiberMax™ and the Pellenc Mistral™. Machine vision company Bühler is even working on camera-based sorting systems that can spot plastics as small as a grain of rice.

Flotation Tanks and Hydrocyclones

Other cool sorting methods use water and gravity:

- In flotation tanks, some plastics float while others sink so they can be separated

- Hydrocyclones spin the plastic in water – denser types get flung to the sides while lighter ones stay in the middle

These use less energy than NIR sorting but the plastic has to be washed and dried a lot.

Cleaning Plastic: Better Washing, Less Water

Getting plastic clean is key for recycling. Any food, dirt, chemicals, or sticky labels have to come off. Traditionally, this meant dunking the plastic in big baths of soapy water or harsh solvents. It used a ton of water and energy. Some bits would still stay dirty. But new cleaning methods are much more efficient.

Friction Washers

High-speed friction washers are one solution. They tumble the shredded plastic bits with small particles like ceramic beads or sand. All that rubbing knocks off contaminants. The special Dyna Wash system adds CO2 “snow” that freezes sticky stuff so it pops right off. Way less water is needed.

Ultrasonic Cleaning

Another innovation is using ultrasonic vibrations to clean plastic. The plastic goes in a big tub of water. High frequency sound waves create tiny bubbles that rapidly form and collapse, blasting dirt off the plastic surfaces. It works great for fine plastic powders. Italian company Fimic has an impressive ultrasonic system called Polar.

Purifying Plastic: Removing Additives, Odors, and Colors

Even after sorting and cleaning, recycled plastic pellets are often not as pure as virgin plastic. They might contain traces of additives, absorb funky smells, or have a cloudy color. This can make it hard to use recycled plastic for food packaging or products that need to look nice. Advanced new processes are helping purify recycled plastic.

Vacuum Distillation

When heated in a vacuum chamber, plastic lets off gases from leftover solvents and additives. The plastic itself doesn’t burn. This vacuum distillation can pull out impurities without hurting the plastic. German manufacturer Coperion has a vacuum system that makes crystal clear recycled PET pellets, pure enough for water bottles.

Deodorization and Bleaching

Sometimes smelly compounds get embedded in plastic. They have to be broken down chemically. This can be done by exposing the plastic to ozone gas or soaking it in a peroxide solution. To brighten dingy plastic, some recyclers use a chlorine dioxide bleaching process. These systems have to be designed carefully to fully remove the odor and color without degrading the plastic too much.

Repelletizing Plastic: Squeezing Out Fresh Material

The last step is usually to melt down the recycled plastic and squeeze it through a die to make small pellets. This repelletizing makes the plastic easy to transport and use for manufacturing. Advanced extruders and melt filtration systems are improving the quality and consistency of recycled pellets.

Twin-Screw Extruders

Fancy twin-screw extruders are becoming the norm. Two long, turning screws mix and heat the plastic very evenly as they push it forward. Extra ingredients can be added for custom recycled blends. Top of the line models like the Cincinnati Milacron TC86 have precise digital controls and monitoring. They can handle high volumes with minimal downtime.

Continuous Melt Filters

Very fine screens called continuous melt filters remove any remaining contaminants as the plastic is extruded. These have to be made of super durable materials to withstand the immense heat and pressure. The latest designs have automatic cleaning mechanisms so they can run without clogging. Examples include the BKG HiCon K-SWE-4K-75/RS and the Ettlinger ERF350.

The Future of Plastic Recycling

With all these incredible innovations, you might be wondering – what’s next for plastic recycling technology? Here are some exciting areas to watch:

Chemical Recycling

Chemical recycling breaks plastic all the way down to its basic building blocks, which can then be rebuilt into new plastic. This could allow more types of plastic to be recycled over and over without loss of quality. Several pilot plants are now testing chemical recycling at an industrial scale.

Robotic Sorting

While optical sorters are fast, they can’t always tell the difference between plastics that look similar. Using AI-powered robots to sort by touch as well as sight could improve accuracy. The RoCycle system developed at MIT combines a pressure sensor and near infrared scanner in a soft robotic hand.

Blockchain Tracking

Blockchains could be used to securely track recycled plastics through the whole supply chain, from collection bin to final product. This would increase traceability and trust in recycled material quality. The company Empower is piloting a blockchain-based platform for plastic recycling.

A Cleaner Future Through Innovation

The rapid progress in plastic recycling machinery is super exciting. These cutting-edge technologies are making it more efficient and economical to give plastic a second life. Of course, we still need to work on reducing plastic use in the first place. But by recycling the plastic we do use, we can conserve resources and protect the planet. As recycling tech keeps getting better, a cleaner future is looking more possible every day.