Buy JianTai Plastic Pelletizing Machine

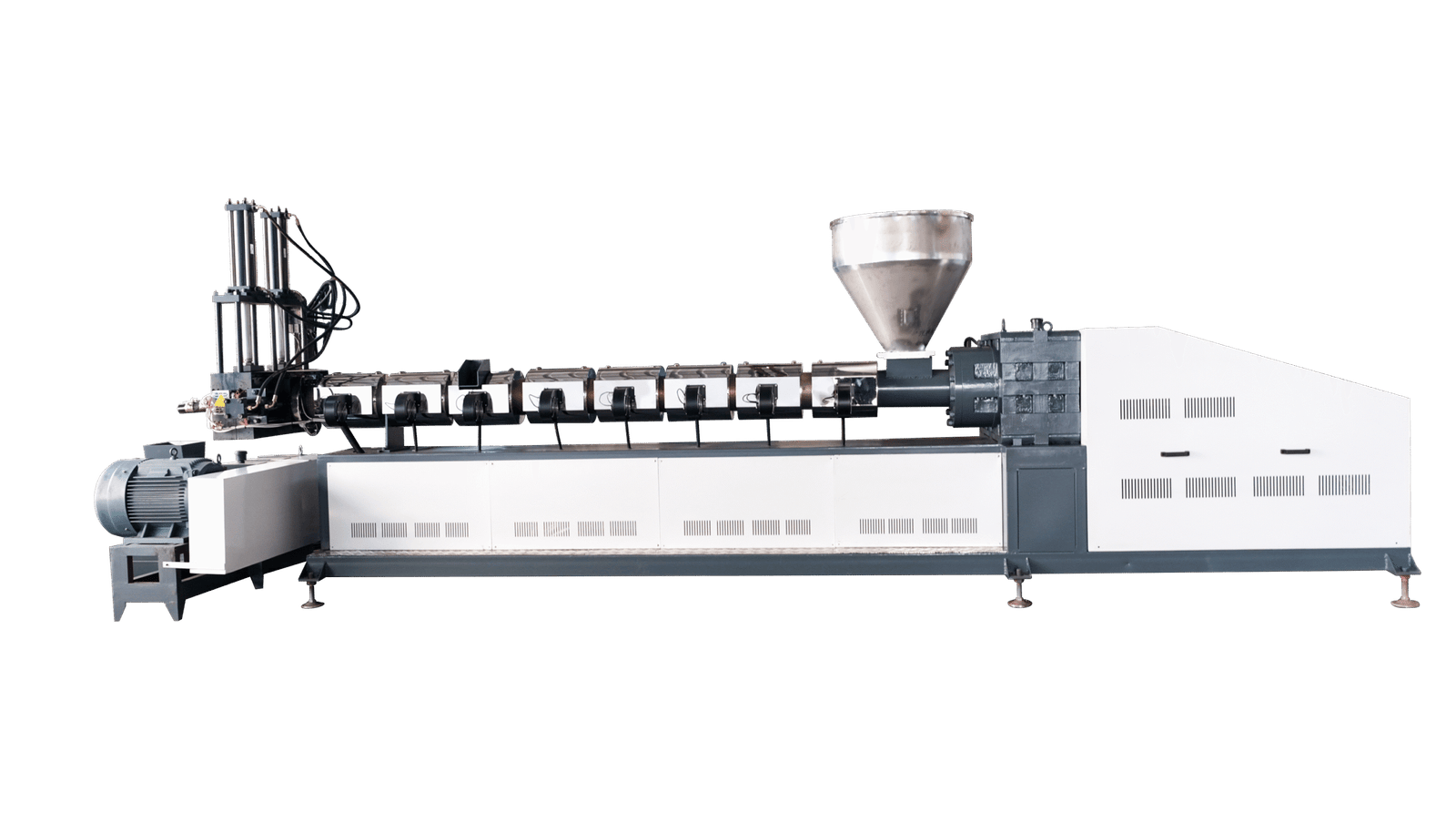

Established 19 years ago, JianTai leads the industry with its advanced Plastic Pelletizing Machine.

Selection of High Quality Plastic Pelletizing Machine

Recycled Plastic Extruder – 30% Energy Savings

$9,600.00 – $38,600.00Price range: $9,600.00 through $38,600.00

PVC Plastic Recycling Machine

$9,600.00 – $38,600.00Price range: $9,600.00 through $38,600.00

What is a Plastic Pelletizing Machine?

A plastic pelletizing machine is a special device used in factories that make plastic products. First, it takes big chunks of plastic and then turns them into tiny beads called pellets. Consequently, factories find it easier to use these small pellets when making everyday items like water bottles, toy bricks, and car parts.

You see, the pelletizing machine acts like a big food processor for plastic. First, the machine chops the plastic into the perfect size, making it ready for factories to melt down and shape into new products. Consequently, by creating these small, uniform pellets, the machine helps the factories work more efficiently. This means they can create less waste and make more products while using less energy and materials. Therefore, this is good for the environment too.

The next time you see a plastic item, remember how it began as a tiny pellet made by these amazing machines!

Working Principle of Plastic Pelletizing Machine

Why Choose Jiantai Plastic Pelletizing Machine

High-quality construction

JianTai uses the newest technology in their machines. Consequently, this helps the machines work smoothly and make pellets that are all the same size. Additionally, it keeps the quality of the pellets high.

Advanced technology

JianTai uses the latest technology in their pelletizers to make sure they work well. This advanced technology helps produce even pellets and, as a result, keeps the quality high.

Multi-functional

With different pelletizer models that can handle various types of plastics, JianTai always has the right solution for you. Therefore, no matter what kind of plastic you need to process, JianTai can help.

Energy efficiency

JianTai’s pelletizer machine saves money by using less energy, which is better for the environment. As a result, it helps the planet and is cost-effective, making the process both eco-friendly and affordable.

User-friendly design

Equip JianTai machines with easy-to-use controls and simple access for maintenance. This makes them easier to operate and, as a result, cuts down on the time needed for cleaning and repairs.

Excellent customer support

JianTai gives full customer support with technical help, training, and service after you buy the machine. As a result, this ensures that your pelletizer fits well into your production line and works perfectly.

JianTai Company excels in the plastic machinery industry with innovative, high-quality solutions. Moreover, they provide outstanding customer-focused service.

Bill

Antecs Company Recommendations

What Features Does a Good Plastic Pelletizing Machine Have?

Consistent pellet size and shape

The machine should make pellets that are the same size and shape. This consistency makes them easy to use and, as a result, ensures high-quality final products.

High output capacity

A good pelletizer should produce a lot of pellets quickly to keep up with manufacturing needs. This speed helps reduce downtime and, as a result, ensures efficient production.

Low energy consumption

Using energy-efficient motors, optimized cooling systems, and well-designed parts can lower energy use and operating costs. Consequently, this helps save money and benefits the environment.

Durability and reliability

Build the pelletizer with high-quality, durable materials to handle constant use. As a result, this design reduces the need for maintenance and ensures the machine lasts longer.

Multi-functional

A good pelletizer should handle different types of plastics, including recycled ones, with only a few adjustments. This versatility makes it easier to use and more efficient.

Precision temperature control

Accurate temperature control ensures the plastic melts and processes correctly. As a result, this produces high-quality pellets.

Safety features

The machine should have safety features like emergency stop buttons, protective guards, and sensors. These features help keep operators safe while using the machine.

Easy maintenance and cleaning

Design the pelletizer with easy access to important parts. As a result, this makes maintenance and cleaning quicker and simpler.

Automated operation

Automatic features like self-feeding, cutting, and moving pellets help the machine work faster. As a result, it needs fewer workers to operate.

Other Types Of Plastic Pelletizing Machine

Single Screw Plastic Pelletizing Machine

Efficient Two Stage Pelletizer Machine

JianTai Plastic Pelletizing Machine Detailed Configurations

PLC Touch Panel Control System by JianTai Company

In this rapidly changing world of plastic recycling, control systems are the nuts and bolts of how to make things run smoothly. One of the top plastic recycling machine manufacturers, JJianTai decided to advance this machinery with modern touch screens so users can navigate operations in an easier manner.

Overview of PLC Touch Panel Control System

PLC touch panel control system of JianTai si designed, in this way enables users to operate and observe the machinery with ease Advanced Technology and it also had to be easy to operate (in such a way that even a lay man who may not have technical knowledge can use it).

Military Grade Extrusion Screw by JianTai Company

In the world of plastic recycling and pelletizing, the quality and durability of machine components are crucial. One key part that greatly affects the efficiency and lifespan of pelletizing machines is the extrusion screw. For example, JianTai Company, a leader in making plastic recycling machinery, proudly uses military-grade extrusion screws in their equipment. This ensures top-notch performance and, as a result, exceptional reliability.

What is a Military Grade Extrusion Screw?

Design and manufacture a military-grade extrusion screw using advanced materials and processes usually reserved for military use. As a result, engineers create these screws to endure extreme conditions and heavy wear. Therefore, they ensure outstanding durability and performance in industrial settings.

Fully Intelligent Temperature-Controlled Cooling Device

One of the best plastic recycling machine makers, JJianTai, chose to upgrade their machines with modern touch screens so people can use them more easily.

Overview of the Fully Intelligent Temperature-Controlled Cooling Device

JianTai’s PLC touch panel control system is designed to make it easy for users to operate and watch the machines. It uses advanced technology and, at the same time, is made simple to use, even for someone who isn’t technical.

JianTai Plastic Pelletizing Machine Case Video

Advantages of JianTai Plastic Pelletizing Machine Manufacturer

JianTai is very good at making plastic granulators. Their machines use new technology and can make a lot of plastic quickly. You can also customize the machines to fit your needs. The machines are strong and last a long time. They are easy to use and don’t cost much to fix. JianTai has great customer service and cares about the environment. Their prices are fair. You can find JianTai machines all over the world, so many companies can use their high-quality plastic granulators.

Questions About Plastic Pelletizing Machine

What are the differences between various types of plastic pelletizing machines?

This question looks at the main differences and uses of different types of plastic pelletizing machines, such as single-screw and twin-screw pelletizers.

How to choose a plastic pelletizing machine that suits your needs?

This question helps buyers understand what to look for when buying a plastic pelletizing machine, including capacity, material handling, and energy efficiency.

What are the essential maintenance steps for a plastic pelletizing machine?

Learn how to maintain and service a plastic pelletizing machine to keep it running efficiently and, at the same time, extend its lifespan.