Did you know a single factory can use over 100,000 tons of plastic pellets yearly? These small, cylindrical pieces are key to the plastics world. They start as raw material and turn into many plastic products.

Plastic pellets are vital for many industries, like medical and auto parts. They can be made to fit exact needs. This lets companies create products in many shapes, sizes, and uses.

Key Takeaways

- Plastic pellets, also known as resin pellets, are the foundational raw materials for the plastics industry.

- These small, cylindrical pellets can be tailored to meet specific manufacturing requirements, allowing for the production of a diverse range of plastic products.

- Plastic pellets are essential for industries ranging from medical to automotive, providing versatility and cost-effectiveness.

- Proper disposal and recycling of plastic pellets are crucial to mitigate environmental impact.

- The plastics industry continues to innovate, exploring new applications and sustainable manufacturing processes for plastic pellets.

What Are Plastic Pellets?

Definition and Composition

Plastic pellets are small, round or flat pieces, about 2 to 5 millimeters big. They are made of polymers, mostly man-made, but sometimes organic. These polymers are long chains of molecules.

Common polymers in these pellets are polyethylene, polypropylene, PVC, and polystyrene. They are the main part of the pellet.

But, plastic pellets also have additives. These can be stabilizers, colorants, or agents that make the plastic stronger. These additives change the plastic’s properties for different uses.

| Plastic Pellet Composition | Percentage |

|---|---|

| Polymers | 70-90% |

| Additives | 10-30% |

The making of plastic pellets involves hydrocarbon and polymerization processes. By choosing the right polymers and additives, makers can create high-quality pellets. These pellets are used in many industries for different needs.

“Plastic pellets are a crucial material in modern manufacturing, enabling the creation of a wide range of plastic products through injection molding and other processes.”

Benefits of Using plastic pellet

Versatility and Cost-Effectiveness

Plastic pellets are very versatile. They can be made to fit exact needs. This makes them key in many fields like packaging, cars, medicine, and building.

They are also very affordable to make. The materials needed are cheap and easy to find. Plus, they are light but very strong, which is great for many uses.

The versatility and cost-effectiveness of plastic pellets make them popular everywhere. They are a smart choice for making things today.

“Plastic pellets are a game-changer in the manufacturing industry, offering unparalleled versatility and cost-effectiveness that drive innovation and efficiency.”

Plastic pellets are used in many ways. They help make car parts, safe packaging, and medical tools. They are very important in today’s world.

The Journey of Plastic Pellets

The journey of plastic pellets is fascinating. It starts with raw materials, mainly polymers. These are mixed and bonded into long chains through polymerization.

Next, these polymers are turned into small, uniform plastic pellets. Then, they go through extrusion or injection molding. Here, they are melted, shaped, and cooled into the final product.

After that, the products are trimmed, packaged, and checked for quality. This ensures they meet high standards.

The final step is packaging and distribution. Plastic pellets are used in many things, like household items and car parts. They play a big role in today’s world.

| Polymer Composition | Global Reach | Cost-Effectiveness | Sustainability |

|---|---|---|---|

| Polyethylene, Polypropylene, PVC, Polystyrene | Over 85 countries served by EuroPlas | A key factor in the widespread adoption of plastic pellets in manufacturing | Recyclability of plastic pellets contributes to waste management efforts |

The journey of plastic pellets shows their versatility. From polymers to everyday products, they drive innovation in manufacturing.

“The future of plastics lies in developing more sustainable solutions, from bioplastics to fully biodegradable materials and recycling processes that convert waste back into useful resources.”

As demand for plastic products increases, so does focus on the plastic pellet life cycle and plastic pellet manufacturing. New technologies aim to make production more sustainable and efficient.

Manufacturing Processes

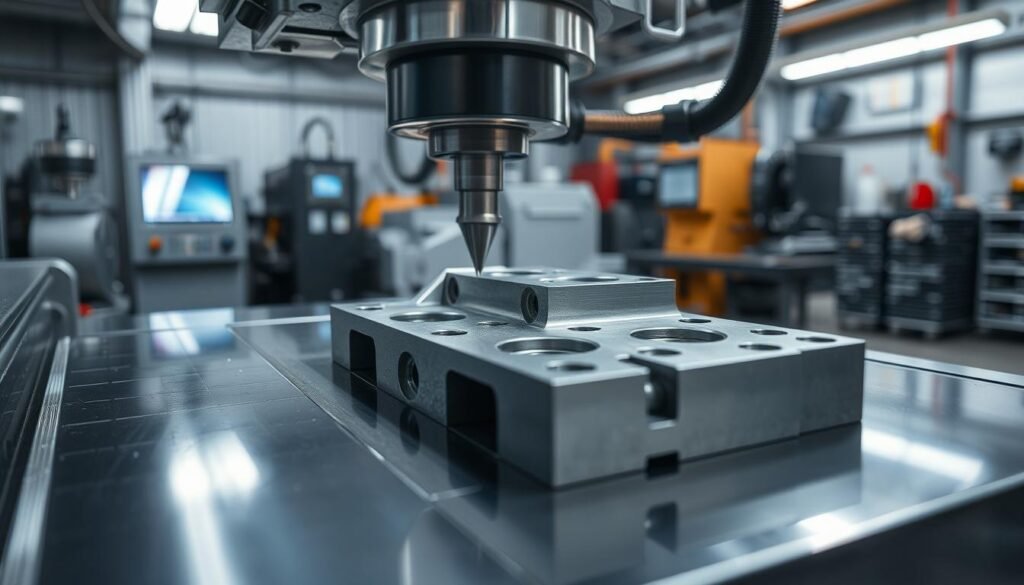

Plastic pellets are the base for many products. They go through different making processes. Injection molding and extrusion are two main ways in the plastic world.

Injection Molding and Extrusion

Injection molding is a detailed and quick method. It turns molten plastic pellets into specific shapes in molds. This is great for making lots of items with complex designs.

Extrusion melts the pellets and pushes them through a die. This makes shapes like pipes or packaging materials.

Both methods use plastic pellets to make many products. The right choice depends on how many items are needed, their design, and the material’s properties.

Choosing between injection molding and extrusion is key in making plastics. It affects how well, how good, and how affordable the products are. Companies must pick wisely to meet market needs.

Applications and End-Use Industries

Plastic pellets are key in many industries. They help make lots of plastic products we use every day. These small pieces of plastic are very useful.

In the packaging world, they make containers, films, and more. The building sector uses them for strong pipes and insulation. Cars also use them for parts that make them lighter and better.

In healthcare, they make medical tools and prosthetics. The electronics field uses them for casings and circuit boards. This shows how plastic pellets are everywhere.

| Industry Sector | Plastic Pellet Applications |

|---|---|

| Packaging | Containers, films, protective packaging |

| Construction | Pipes, insulation, building materials |

| Automotive | Lightweight components, fuel-efficient parts |

| Healthcare | Medical devices, prosthetics, drug delivery |

| Electronics | Casings, circuit boards, components |

Plastic pellets are very flexible. They fit many needs in different industries. As we need more plastic products, their uses will grow too.

“Plastic pellets are the base for almost all plastic items. They protect our food and power our gadgets. Their flexibility and value make them crucial today.”

Environmental Considerations

Plastic pellets are key to many products we use daily. Their small size makes them easy to spill and lose. This leads to more plastic pollution and harms wildlife, especially in waterways.

Manufacturers must follow strict rules to keep plastic pellets safe. They need to manage waste well and recycle these materials. This helps reduce plastic waste and supports a circular economy.

- Over 445,000 tonnes of plastic pellets leak out of the global plastic supply chain directly into the environment every year.

- Sound pellet loss prevention measures that are maintained and monitored for effectiveness could reduce pellet loss by 95%.

- Plastic pellets are the third-largest source of microplastic pollution globally.

New policies to stop pellet spills are being made in some places. But they don’t cover the whole world. The Plastic Pellet Free Waters Act in the U.S. Senate wants to change this. It aims to cut down on plastic pellet loss worldwide.

Plastic pellet pollution harms nature, communities, and economies worldwide. It can hurt wildlife and even people. Spills damage local ecosystems, communities, and industries like fishing and tourism.

We need a big plan to tackle plastic pellet pollution. This includes better ways to analyze and manage waste. By focusing on sustainability, the plastic industry can lessen its impact. This helps us move towards a greener future.

Quality Control and Testing

Keeping plastic pellets quality high is key in making them. From picking raw materials to the final product, strict quality checks are done. This ensures the plastic parts meet the needed standards and specs.

Tests like X-ray cameras, optical cameras, and ultrasonic checks find contaminants and check material makeup. These tools, made by leaders like SIKORA, help spot 100% purity during making. This means the final products are clean and without flaws.

Melt flow tests, moisture checks, and radiographic tests are also important. They help understand how the plastic acts during molding and extrusion. This lets makers improve their work and make durable plastic parts for many industries.

Online and offline checks work together to fully check material purity. This helps ensure quality, solve problems, and improve processes. It shows the industry’s dedication to making top-notch plastic products for today’s needs.

“Advanced Plastiform, Inc. boasts a 98% customer return rate, indicating high-quality, durable plastic components with low per-unit cost and fast lead times.”

The plastic making world focuses a lot on plastic pellet quality control, plastic product testing, plastic manufacturing standards, and plastic product specifications. This shows their aim for the best. By using the latest tech and strict quality checks, makers can meet customer needs in many fields.

Innovations and Future Trends

The world of plastic pellets is changing fast. New technologies and a focus on being green are leading the way. This means plastic pellets will soon be more sustainable and useful than ever before.

Material science is getting better all the time. Companies are making new kinds of plastics and using green additives. They’re also finding ways to make plastics more efficiently. The Plastic Pellet Market is expected to grow at a CAGR of XX% from 2024 to 2031, with the market valuation projected to increase from USD XX Billion in 2023 to USD XX Billion by 2031.

New plastic technologies are changing the game. Companies are using the Internet of Things (IoT) to make things better. They’re making products lighter to save resources and be more efficient.

- Automation and customization trends in manufacturing are providing producers with enhanced flexibility and efficiency, allowing for more personalized products and increased bottom-line impact.

- Recyclability is a key focus, with efforts towards creating single recyclable material packaging and innovative solutions to improve plastics’ recyclability while retaining desired qualities.

- Collaboration between manufacturers, brand owners, recyclers, and other stakeholders is driving the development of waste management solutions that optimize utility and support sustainability efforts in the plastic sector.

The plastic industry is always getting better. Innovative solutions and sustainable plastic technologies are changing how we see plastic pellets. They’re helping make the industry more eco-friendly for our future.

“The future of the plastic industry lies in its ability to adapt, innovate, and embrace sustainability. By leveraging emerging technologies and fostering collaborative efforts, we can unlock the true potential of plastic pellets to positively impact our world.”

Conclusion

Plastic pellets are key in making many plastic products. They are made cheaply and can be used in many ways. This makes them very important in today’s world.

The plastics industry is always changing. It needs to think about the environment more. Plastic pellets help meet the needs of people and businesses everywhere.

Plastic pellets do more than just make products. They can be recycled and made into new things. This helps the environment and makes a better future.

New technology can make recycled plastic pellets even better. This opens up new uses in many fields.

But, the industry must think about the environment too. It needs to find ways to clean up pollution and manage waste better. This will protect our planet and the creatures in it.

By finding a balance, the industry can keep making plastic pellets. But it must do so in a way that is good for the planet. This will help ensure a sustainable future for all.

FAQ

What are plastic pellets?

Plastic pellets are the base of the plastics world. They are small, round pieces that turn into many plastic items. This happens after they go through different changes.

What is the composition of plastic pellets?

Plastic pellets are made mostly of synthetic polymers. Sometimes, organic compounds are added too. Polymers like polyethylene and polypropylene are common. Additives like colorants and stabilizers are also used to improve the pellets.

What are the key benefits of using plastic pellets?

Plastic pellets are very versatile and cost-effective. They can be made to fit specific needs. They are also lightweight but strong, making them useful in many areas.

What are the typical manufacturing processes for plastic pellets?

There are two main ways to make plastic pellets: extrusion and injection molding. Injection molding shapes melted pellets into specific forms. Extrusion melts pellets into shapes like pipes or packaging materials.

What are the common applications of plastic pellets?

Plastic pellets are used in many fields. They are in packaging, construction, healthcare, and electronics. Their versatility makes them useful in many products.

What are the environmental considerations related to plastic pellets?

Plastic pellets can spill and pollute during making. They can harm wildlife if they get into water. It’s important to manage waste and use recycled pellets to help the environment.

How is quality control maintained for plastic pellets and products?

Quality control is strict from start to finish. Tests check the pellets’ strength and size. This ensures the final products meet standards and designs.

What are the future trends and innovations in the plastics industry?

The plastics industry is always changing. New technologies and a focus on sustainability drive these changes. Manufacturers are making better, greener plastics and finding new ways to make them.

Source Links

- https://novastevensville.com/versatile-industrial-raw-material-a-guide-to-resin-pellets/

- https://www.polyvisions.com/plastic-pellets/

- https://kbdelta.com/blog/plastic-pellets-granules/

- https://www.imo.org/en/MediaCentre/HotTopics/Pages/FAQ-Plastic-pellets.aspx

- https://www.polystarco.com/blog-detail/why-to-use-recycled-plastic-pellets-for-injection-molding-instead-of-regrinds/

- https://scrapmanagement.com/blog/what-is-plastic-pelletizing/

- https://www.vismec.com/en/news/plastic-granules-applications/

- https://europlas.com.vn/en-US/blog-1/plastic-pellets-from-raw-materials-to-products

- https://www.up.com/customers/track-record/tr020420-transportation-and-plastics.htm

- https://formlabs.com/blog/guide-to-manufacturing-processes-for-plastics/

- https://www.shell.us/about-us/projects-and-locations/shell-polymers/shell-polymers-plant/polyethylene-pellets.html

- https://www.asyousow.org/our-work/circular-economy/plastic-pellets

- https://www.linkedin.com/pulse/analyzing-plastic-pellet-market-global-industry-perspective-58eyc

- https://www.fauna-flora.org/wp-content/uploads/2024/04/INC4_fauna-flora-pellet-primer.pdf

- https://www.arcadis.com/en-us/knowledge-hub/blog/united-states/david-gerber/2021/plastic-pellets-what-to-do-about-emerging-concerns

- https://sikora.net/en/material-inspection/

- https://advancedplastiform.com/how-to-test-the-quality-of-plastic-components/

- https://www.linkedin.com/pulse/plastic-pellet-market-size-future-trends-anticipating-n6daf

- https://prototool.com/plastic-products-company/

- https://www.geording.com/en/news-detail/the-importance-of-plastic-pellet-recycling

- https://elgee.com/blog-post/detail/how-destructive-are-plastic-pellets-to-humans-and-animals-3/

- https://ipen.org/sites/default/files/documents/ipen-beach-plastic-pellets-v1_4aw.pdf