In this article, we’ll delve into how plastic products are produced starting from their primary sources: crude oil and natural gas. These substances undergo a transformation process to create polymers, which serve as the foundational elements of plastic. We will explore the journey these resources take to become the everyday plastic items we utilize, such as plastic bottles.

Key Takeaways

- Plastics are versatile materials made from polymers, primarily derived from carbon-based elements, enabling a wide range of applications but also raising concerns about waste and pollution.

- The evolution of synthetic plastics from natural materials began in the 19th century, with key innovations like Bakelite and polyethylene, driven by the need for cost-effective and versatile alternatives.

- Environmental challenges associated with plastic production and waste emphasize the importance of developing biodegradable alternatives and adopting sustainable manufacturing practices.

Understanding Plastic: Definition and Basic Composition

Plastic is essentially a collection of malleable materials designed to be formed into various shapes through the application of heat and pressure, an innovation that has transformed both manufacturing and consumer products. These substances consist primarily of elements such as carbon, hydrogen, oxygen, nitrogen, sulfur, chlorine, and silicon. When these elements are combined in numerous ways, they give rise to an extensive range of plastic varieties. At the core of this versatility lies polymers—large molecules made up by linking together repeated smaller entities called monomers—that dictate the structural characteristics and properties.

The concept ‘plasticity’ describes plastics’ ability to mold into myriad forms without fracturing—a trait rendering them invaluable across a multitude of landscapes. The manipulability inherent in their chemistry enables refinement towards specific attributes. Plastics can be crafted light yet robustly durable with multifaceted adaptability — essential features for many uses. Amongst plastics are types known as resins, which possess distinctive chemical compositions bolstering their function within particular applications.

These advantageous qualities have established plastics as fundamental components within modern production processes: from everyday household goods to sophisticated machinery parts – owing largely to its amenability alongside resilience – making it often the material choice for diverse industry sectors. Such convenience introduces significant predicaments associated with plastic waste management challenges we shall delve into later on.

A basic understanding regarding how plastics come about along with recognizing traits renders insight not only about why its utility spans so broadly but also raises awareness concerning implications around excess leftover synthetics leading to environmental degradation discussions. By grasping these rudiments, we’re poised aptly when dissecting historical advancements pertaining to synthetic variants aloft innovations at the helm propelling forward advancement surrounding the entire sphere involved in manufacture plus disposal relating back upon overarching themes circling consumption consequent outflows intrinsic tying back our today’s narrative threading throughout existence entwined plastic matter holding tight web spinning forth riveting unfolding era coursing reality ours tackle ahead us steps trodden careful contemplace succession unfold midst clear

The Birth of Synthetic Plastics

The journey of synthetic plastics began in the mid-19th century with the invention of Parkesine, the first man-made plastic. Created from cellulose treated with nitric acid, parkesine offered a cost-effective alternative to natural materials like ivory and horn, which were becoming increasingly scarce. This innovation marked the beginning of a new era in material science, driven by the need to find substitutes for dwindling natural resources.

Parkesine’s ability to mimic more expensive materials led to its use in everyday items such as buttons and combs, showcasing the potential of synthetic alternatives. Subsequent advancements saw the development of celluloid, derived from parkesine, which found applications in photography and motion pictures, further demonstrating the versatility and utility of early synthetic plastics. These early innovations laid the groundwork for the more complex synthetic materials that would follow.

Transitioning to synthetic plastics involved not only replacing scarce natural resources, but also enhancing material properties for broader applications. The creation of the first fully synthetic plastic, Bakelite, in 1907, marked a significant milestone. Unlike its predecessors, Bakelite contained no natural molecules, making it entirely synthetic and setting the stage for the modern plastics we use today.

As we moved into the 20th century, the plastics industry continued to evolve, driven by the demand for new materials that could meet the needs of an industrializing world. The development of synthetic plastics represented a significant leap forward in human manufacturing, enabling the production of a wide range of products that were previously unimaginable.

From Natural Substances to Synthetic Marvels

Prior to the emergence of synthetic plastics, various products were made from natural materials such as horn, tortoiseshell, natural rubber, and shellac. These substances, sourced from fauna and flora, faced constraints in both supply and physical properties which led to a pursuit for more adaptable solutions. The lack of naturally-sourced items like ivory and turtle shells catalyzed significant advancements in creating man-made equivalents.

The synthesis of the first artificial polymer in 1869 marked a pivotal moment that offered an alternative solution to conventional materials including ivory. With John Wesley Hyatt’s invention of celluloid came a transformative change within manufacturing sectors by enabling the replication of natural substances while conserving biological resources. This breakthrough tackled issues associated with scarcity while simultaneously unlocking new possibilities for consumer goods production.

With petrochemical-derived synthetic plastics coming into play, there was a remarkable shift within material sciences. Extracted from crude oil and natural gas sources, these synthetic or semi-synthetic compounds presented unmatched flexibility along with expansive uses which laid down the foundations for today’s thriving plastics industry. Making this leap from organic-based elements to synthetically engineered ones has brought about substantial changes in how products are manufactured, making way for numerous commodities that have become essential features of contemporary living.

However, the use of polystyrene food containers has raised significant environmental and health concerns. These containers can leach harmful chemicals, suspected human carcinogens, and hormone disruptors, into food. Additionally, the degradation of polystyrene contributes to plastic pollution, posing broader environmental issues.

Key Raw Materials in Plastic Production

Plastic production is heavily dependent on a myriad of raw materials, primarily sourced from crude oil and natural gas. These resources are refined to create the essential components for synthetic plastics, such as ethylene and propylene. Through the distillation process in refineries, crude oil is broken down into lighter fractions including naphtha – a pivotal ingredient for producing plastic.

Crucial monomers like ethylene and propylene stem from naphtha and serve as fundamental building blocks in polymerization to manufacture diverse types of plastics. These hydrocarbons undergo chemical reactions that result in long polymer chains at the core of most plastic products. The ability to vary these monomer combinations enables manufacturers to produce an expansive range of plastic items that cover simple household goods to intricate parts used industrially.

Beyond just using crude oil and natural gas, the creation of plastics also utilizes additional natural substances such as cellulose, coal, and salt. Post chemical conversion into polymers capable of being shaped differently. This aspect emphasizes the petrochemical industry’s significant role by supplying necessary materials which are then honed into constituents vital for crafting various plastic objects. Additionally, the use of recycled plastic in the production process is becoming more prevalent. However, recycling plastic presents challenges due to the presence of additives and the need for proper sorting to produce high-quality recycled materials.

Grasping both how raw materials transform during processing sheds light upon complex nuances underlying contemporary methods utilized within modern-day manufacturing efforts involving synthetics like plastics—thereby drawing attention toward interconnections linking naturally-occurring resources with human-made compounds while simultaneously reinforcing considerations regarding environmental ramifications tied with ongoing developments across disciplines dedicated towards sustainable progressions throughout global sectors related especially pertaining advancements concerning next-generation material sciences collectively Along our timeline ahead.

The Polymerization Process

At the heart of plastic production lies the polymerization process, a chemical reaction that links monomers into long chains called polymers. This process is fundamental to creating synthetic plastics, providing the structure and properties that make these materials so versatile. There are two main types of polymerization: addition and condensation.

Addition polymerization involves sequentially adding monomers to form a longer chain without producing byproducts. This method is commonly used to produce plastics like polyethylene and polypropylene, which are known for their strength and flexibility.

On the other hand, condensation polymerization joins different monomers while releasing small molecules like water as byproducts. This method is used to create materials such as nylon and polyester, which have unique properties suitable for various applications.

The polymerization process generates thick resins that can be shaped into a variety of forms through processes like injection molding, extrusion, or blow molding. These techniques allow manufacturers to produce a wide range of plastic products, from simple containers to complex components used in the automotive and aerospace industries.

Appreciating the complexity and versatility of synthetic plastics requires understanding the polymerization process. It highlights the intricate chemical reactions that transform simple monomers into durable and adaptable materials, paving the way for the wide array of plastic products that we use every day.

Evolution of Modern Plastics

The progression of modern plastics is defined by key moments, beginning with the introduction of Bakelite in 1907. This novel substance was the first fully synthetic plastic and did not contain any molecules derived from natural substances, representing a pivotal moment for materials science. Its capacity to serve as an insulator for electrical purposes and its use in products such as radios and telephone cases quickly proved its adaptability and resilience.

Polyethylene’s emergence in 1935 transformed the plastics industry due to its robustness, malleability, and thermal resistance characteristics. As it became integral across numerous domains ranging from packaging to building industries, polyethylene established itself as one of the most utilized forms of plastic. PET (polyethylene terephthalate) debuted in 1973, enhancing advancements, particularly within beverage industry circles, through its light weightiness coupled with shatterproof nature.

During World War II, substantial advances were made regarding both development & dissemination rates for various kinds of synthetic polymers including nylon & Plexiglas, which saw heavy military use owing largely to their durability & multi-purposefulness even in high-stress situations. Following conflict cessation these versatile replacements found new life replacing more traditional resources thanks also largely to economic viability paired alongside flexibility design-wise post-1945 era rolled around thus becoming commonplace fixtures day-to-day existence various sectors alike attributable to cost savings plus adaptable attributes therein provided thereof subsequently.

Reflecting persistent innovation efforts complemented respective adaptational abilities inherent to the material sciences domain overall. Starting out early iterations involving synthetically produced polymer compounds up until present where advanced derivative forms are presently deployed – so goes story ongoing evolution associated with these influential shaping forces that have undeniably helped carve shape societal structure dramatically ever since inception back at turn last century onwards hereto forward moving into future unknown still yet ahead time wise speaking About matter hand concerned hereinabove described above comprehensively accordingly without loss crucial informational points intact maintained throughout process entailed therewith summarily concluded this context given essayist outlook perspective offered upon subject underneath discussion here today date cited precedent entry ending line mark finish point reached full stop end zza

The Role of Fossil Fuels

Crude oil and natural gas are critical in the manufacturing of plastics, serving as the fundamental resources for synthetic polymers. These polymers form the foundation of most plastic products available today. The distillation process applied to crude oil yields a variety of petroleum derivatives including naphtha, which is indispensable in generating key monomers such as ethylene and propylene.

Refining processes by the petrochemical industry meticulously convert complex hydrocarbons from fossil fuels into simpler substances that can be used to produce plastics. Techniques like steam cracking and catalytic cracking help break down naphtha into olefins. These molecules are subsequently polymerized to forge various plastic materials. Such cooperation between petroleum extraction and chemical processing has been crucial in enhancing methods for producing plastics while fulfilling an increasing demand for these synthetic materials.

This dependence on fossil fuels within plastic production poses grave environmental concerns due to their role in contributing to greenhouse emissions among other ecological issues. As sustainable alternatives continue to be sought after, understanding how pivotal crude oil and natural gas are within the realm of plastic manufacture remains an important point for both those within its related industries as well as proponents pushing towards greater environmental stewardship.

Environmental Impact of Plastic Production

The widespread production of plastic has given rise to a throwaway culture centered on disposable items, resulting in serious ecological issues. Yearly, countless tonnes of plastic waste find their way into aquatic environments – the equivalent volume thrown into bodies of water every day is about that which 2,000 trash trucks would carry. This accumulation of plastics endangers sea creatures and interferes with natural ecological functions.

Plastic debris in the oceans was first observed in the 1960s, coinciding with an increased awareness of environmental issues. The persistence of plastic debris in marine environments is due to the slow degradation rates of plastics, and recent studies indicate that while plastics decompose faster in certain conditions, the sheer volume of plastic waste continues to hinder these processes.

Not only do ecosystems suffer due to plastic pollution, but it also compromises their capacity for adapting to climate change. The pervasive presence of plastics can disrupt food chains, pollute sources of drinking water and negatively affect societal health. Given its complexity, the threat posed by this type of pollution should be assessed alongside other environmental concerns when devising plans for intervention.

Problematic are the effects that stem from producing these materials. Because manufacturing processes rely heavily on energy consumption and fossil fuels utilization leads to increased greenhouse gas emissions among additional pollutants causing harm globally. Combating these problems necessitates collective action aimed at lessening our reliance on plastics through improved recycling methods as well as seeking out alternative materials that are eco-friendly.

Understanding how production affects our planet plays an instrumental role in cultivating mindful consumer behavior along with supporting innovation efforts towards tackling such challenges head-on.By grasping just how extensive the consequences arising from misuse or overuse might be, gives us all an opportunity to contribute positively—enabling strides forward collectively within reaching greater sustainability benchmarks long term.

Innovations in Biodegradable Plastics

In response to the growing environmental concerns associated with traditional plastics, researchers have been developing biodegradable plastics made from natural materials like corn and plant matter. These biodegradable plastics decompose faster and do not release harmful chemicals, offering a more sustainable alternative to conventional plastics.

One promising development in this field is the use of spirulina, a carbon-neutral algae that can be grown on a large scale. Researchers have created bioplastics from spirulina that can decompose in backyard composting conditions, exhibiting strength and stiffness comparable to conventional single-use plastics. These bioplastics also possess unique fire-resistant properties, adding to their potential applications.

The development of biodegradable plastics aims to provide alternatives that do not require significant changes to existing manufacturing processes. This makes it easier for industries to adopt these new materials without incurring substantial costs or disruptions. As technology advances, the production and use of biodegradable plastics are expected to increase, reducing the environmental impact of plastic waste.

Innovations in biodegradable plastics represent a critical step towards addressing the plastic pollution crisis. By embracing these new materials, we can reduce our reliance on fossil fuels and move towards a more sustainable future.

The Future of Plastic Manufacturing

The evolution of the plastics industry is being influenced by advancing technology and an increasing focus on eco-friendliness. The development of reinforced plastics, which include carbon or aramid fibers, has led to materials that are both strong and lightweight. This makes them exceptionally suitable for use in the automotive and defense sectors. These advanced materials contribute to enhanced functionality and extended product life cycles, leading to a path of more environmentally conscious plastic products.

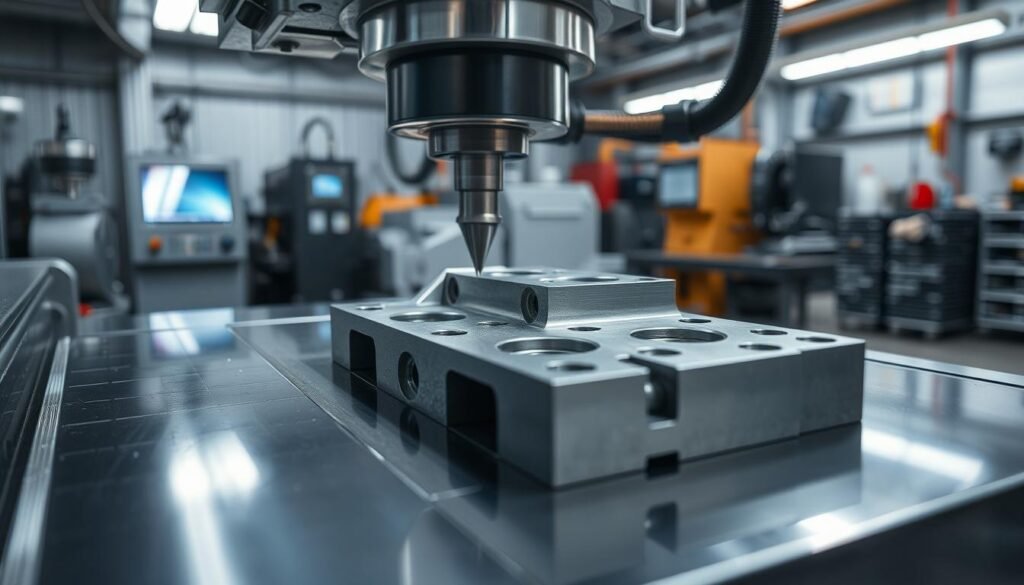

In the realm of manufacturing plastics, automation is becoming crucial. Sophisticated robotics along with precision equipment result in sharper production methods and heightened quality control standards, diminishing waste while improving productivity levels. It’s anticipated that this trend toward automated systems will spur Advancements within the sector, rendering the process of producing plastic both more ecologically sound as well as economically efficient.

Novel technologies like radio frequency identification embedded within plastic are broadening what can be achieved with these substances. By enabling capabilities such as monitoring structural stress or pinpointing locations automatically—the applications relevant to building construction maintenance plus utility management become increasingly proficient—these technological integrations signal a transition towards intelligent plastics geared for long-term sustainability.

As it progresses forward into its future state of being, the impetus placed upon environmental responsibility fuses synergistically with breakthroughs, showing pivotal significance in tackling ecological predicaments entwined with producing various types of synthetics, fundamentally known as ‘plastic.’

With adaptive embracement stemming from emergent material compositions aligned conjunctively alongside pioneering tech discoveries, alliances collectively coalesce efforts, incrementally inching forward. This anticipatory movement heralds an optimistic foresight, envisioning probable upcoming eventualities and foreseeable developments on the horizon.

These advancements push forward, leading the forefront of cutting-edge innovation, where creativity, inventiveness, and originality thrive. As industries conceptualize, devise, and fabricate new solutions, they generate tangible outcomes, materializing ideas into physical reality.

This momentum is sustained through persistent resilience, where strength, vigor, and vitality drive continuous progress. As the world maintains, preserves, and sustains these advancements, they contribute to a steady and unwavering journey toward a more sustainable future.

This journey, marked by exploration and discovery, reveals the importance of innovative strategies and methodologies. It involves not only the creation and implementation of new systems but also the careful refinement and perfection of existing processes, all while navigating the complexities of the modern world.

As industries collaborate and form alliances, they exchange ideas, trade expertise, and contribute to a collective effort. This synergy fosters mutual growth and development, propelling society forward in its quest for progress.

The culmination of these efforts is seen in the realization and actualization of new technologies and materials that enhance and enrich our lives. These innovations are not only aesthetically pleasing but also embody the values of sustainability and environmental responsibility.

As these advancements unfold, they bring about a wave of optimism and anticipation for the future. With each new development, the world moves closer to achieving its goals of sustainability, equity, and progress, ultimately leading to a more harmonious and balanced existence.

This ongoing journey is marked by continuous growth, advancement, and innovation. It is a testament to the enduring spirit of human creativity and the relentless pursuit of a better, more sustainable future for all.

Summary

Tracing the origins of plastic reveals a fascinating journey of human ingenuity and resourcefulness. From the early days of Parkesine and Bakelite to the sophisticated synthetic plastics of today, the evolution of these materials has significantly shaped modern life. However, this journey also highlights the environmental challenges that have emerged alongside the widespread use of plastics.

As we look to the future, the importance of sustainable practices and innovative solutions cannot be overstated. The development of biodegradable plastics and advancements in manufacturing technologies offer promising pathways to mitigate the environmental impact of plastic production. By understanding where plastic comes from and how it affects our world, we can make informed choices and work towards a more sustainable future.

Frequently Asked Questions

What are plastics made from?

Primarily composed of polymers, plastics consist of vast molecules that emerge from the linkage of smaller units known as monomers. These monomers are compounds made up of different elements including carbon, hydrogen, oxygen, and nitrogen.

The unique molecular composition is what gives plastics their wide-ranging characteristics and makes them suitable for a multitude of uses.

What was the first fully synthetic plastic?

Invented by Leo Baekeland in 1907, Bakelite holds the distinction of being the first fully synthetic plastic, marking a significant breakthrough as it consisted purely of man-made molecules.

How do biodegradable plastics differ from traditional plastics?

Plastics that are biodegradable have the advantage of decomposing in a quicker and safer manner thanks to their derivation from natural materials. In contrast, conventional plastics derived from fossil fuels can persist in our environment for centuries.

Emphasizing this fundamental distinction underscores the ecological advantages gained by transitioning to biodegradable alternatives.

What role do fossil fuels play in plastic production?

Crude oil and natural gas are indispensable raw materials derived from fossil fuels, playing a pivotal role in the manufacturing of synthetic polymers for plastic production. These substances undergo refinement to produce naphtha—a key component necessary for synthesizing basic monomers such as ethylene and propylene that are central to making plastics.

What are some emerging technologies in plastic manufacturing?

Innovative developments in the field of plastic manufacturing include plastics reinforced with carbon or aramid fibers, plastics integrated with radio frequency capabilities for infrastructure surveillance, and heightened automation aimed at improving the accuracy and efficiency of production.

Such progressions are forging a new path for the trajectory of the industry.