What is plastic recycling?

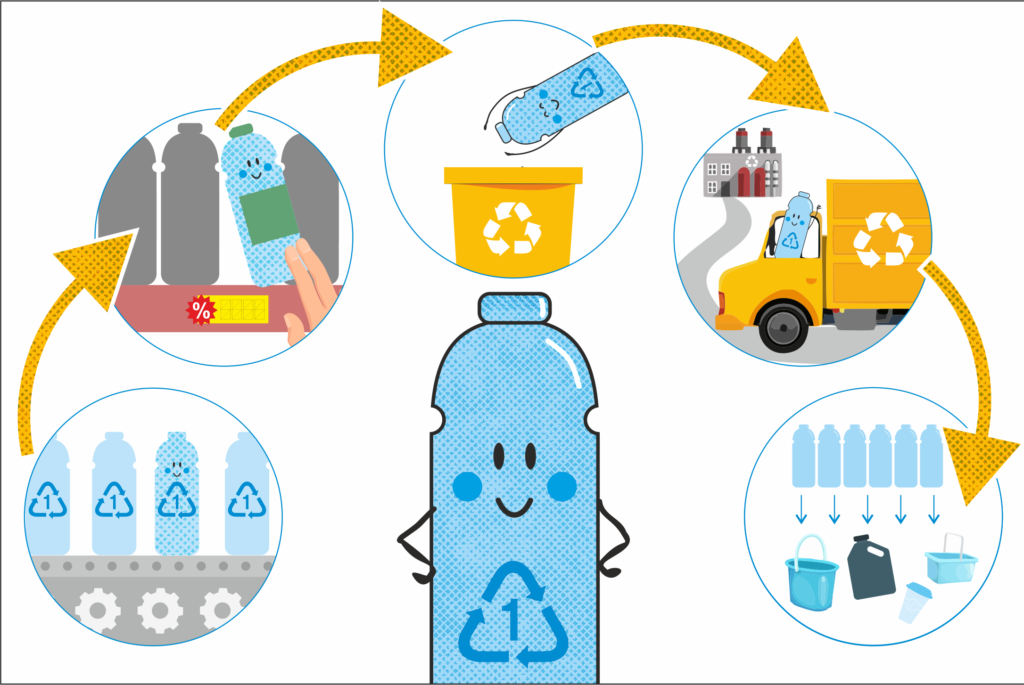

Plastic recycling is the process of recovering used plastics and reprocessing them into useful products. This process contributes to environmental protection by helping to reduce plastic pollution and minimizing the amount of waste going to landfills.

The Process of Plastic Recycling

1. Collection

Plastic recycling begins with the collection of plastic waste. This can come from households, businesses, or industrial sources. The collection process often involves sorting plastics into different types, as different types of plastics need to be processed differently.

2. Sorting

Once collected, plastics are sorted based on their type and color. This is crucial because different types of plastics have different properties and melting points. Sorting can be done manually or using automated systems that use technologies like infrared scanners to identify and separate plastics.

3. Washing

After sorting, plastics are washed to remove contaminants such as labels, adhesives, dirt, and food residues. Clean plastics are essential for producing high-quality recycled materials.

4. Shredding

Clean plastics are then shredded into small pieces called flakes. This makes them easier to handle and further process.

5. Identification and Classification

Shredded plastic flakes are tested to determine their quality and type. This step ensures that the recycled material meets the necessary standards for its intended use.

6. Melting and Extruding

The plastic flakes are melted and extruded into pellets or granules. This is done using specialized machinery. These pellets can then be used as raw materials for manufacturing new plastic products.

7. Manufacturing

The recycled plastic pellets are used to manufacture new products. These can include anything from plastic bottles and packaging to clothing, construction materials, and automotive parts.

How to efficiently utilize recycled plastics?

Utilizing recycled plastics efficiently involves several strategies that ensure the material is used effectively and sustainably. Here are some key approaches:

1. Integration into Manufacturing Processes

- Product Design: Design products with recycled plastics in mind, considering factors such as material properties and compatibility.

- Blending with Virgin Plastics: Mix recycled plastics with virgin materials to maintain product quality while reducing the amount of new plastic required.

- Manufacturing Adjustments: Adapt manufacturing processes to accommodate the specific properties of recycled plastics, such as different melting points or durability.

2. Innovative Applications

- Construction Materials: Use recycled plastics in building materials, such as insulation, roofing tiles, and plastic lumber, which are durable and weather-resistant.

- Textiles: Produce fibers for clothing and textiles, including polyester made from recycled PET bottles.

- Packaging: Develop packaging solutions that incorporate recycled plastics, reducing the reliance on virgin materials for items like bottles, containers, and bags.

3. Product Lifecycle Management

- Design for Recycling: Create products that are easier to recycle at the end of their lifecycle by using fewer mixed materials and incorporating standardized components.

- Extended Producer Responsibility (EPR): Implement EPR programs where manufacturers are responsible for the end-of-life management of their products, incentivizing the use of recyclable and recycled materials.

4. Technological Advancements

- Advanced Sorting Technologies: Utilize technologies such as AI, robotics, and infrared sorting to improve the accuracy and efficiency of separating different types of plastics.

- Chemical Recycling: Invest in chemical recycling methods that break down plastics into their monomers, allowing for the production of high-quality recycled materials.

5. Quality Control and Standards

- Strict Quality Control: Implement stringent quality control measures to ensure that recycled plastics meet the necessary standards for various applications.

- Certification Programs: Participate in certification programs that verify the recycled content and environmental benefits of products, building consumer trust and market demand.

6. Market Development and Consumer Education

- Consumer Awareness: Educate consumers about the benefits of products made from recycled plastics and encourage their purchase.

- Incentives for Businesses: Provide incentives for businesses to use recycled plastics, such as tax breaks, grants, or subsidies.

- Building Markets: Develop and support markets for recycled plastic products through policies, procurement programs, and partnerships.

7. Regulatory Support

- Government Policies: Advocate for and comply with government policies that promote the use of recycled plastics, such as mandates for minimum recycled content in products.

- International Collaboration: Engage in international initiatives and agreements that support recycling and the use of recycled materials globally.

Plastic recycling or where does it apply?

Plastic recycling has a wide range of applications across various industries. Here are some key areas where recycled plastics are effectively utilized:

1. Packaging

- Bottles and Containers: Recycled PET (polyethylene terephthalate) is commonly used to make new bottles and containers for beverages, food, cleaning products, and personal care items.

- Packaging Films: Recycled LDPE (low-density polyethylene) is used in the production of packaging films, grocery bags, and shrink wraps.

2. Construction

- Building Materials: Recycled plastics are used in products like plastic lumber, decking, fencing, and roofing tiles, offering durability and resistance to moisture and pests.

- Insulation: Recycled plastics can be used to create insulation materials that provide thermal and acoustic benefits.

3. Automotive Industry

- Car Parts: Recycled plastics are used to manufacture various automotive components, including bumpers, dashboards, interior trims, and underbody shields.

- Carpet Fibers: PET from recycled plastic bottles is used to create fibers for automotive carpeting and upholstery.

4. Textiles and Fashion

- Clothing: Recycled PET is turned into polyester fibers, which are used to make clothing, shoes, and accessories.

- Textiles: Recycled plastics are used in home textiles like carpets, curtains, and upholstery fabrics.

5. Consumer Goods

- Electronics: Recycled plastics are used in the casings and components of electronic devices such as computers, phones, and televisions.

- Household Items: Products like furniture, toys, and kitchenware often incorporate recycled plastics.

6. Agriculture

- Fencing and Stakes: Recycled plastics are used to make durable fencing and stakes for agricultural use.

- Containers and Pots: Plant pots, seed trays, and containers made from recycled plastics are widely used in nurseries and farms.

7. Infrastructure

- Roads and Paving: Recycled plastic can be used in asphalt mixtures for road construction, enhancing durability and reducing maintenance costs.

- Signage and Barriers: Traffic signs, barriers, and bollards made from recycled plastics offer longevity and resistance to weathering.

8. Furniture

- Outdoor Furniture: Recycled plastics are used to make outdoor furniture such as benches, picnic tables, and playground equipment, which are resistant to rot and weather damage.

- Indoor Furniture: Items like chairs, tables, and shelving units can also be made from recycled plastics.

9. Industrial Applications

- Pallets and Crates: Recycled plastics are used to manufacture durable pallets and crates for shipping and storage.

- Industrial Components: Various industrial parts, including pipes, fittings, and containers, can be made from recycled plastics.

10. Healthcare

- Medical Devices: Certain non-critical medical devices and equipment, such as bedpans, trays, and containers, can be produced using recycled plastics.

- Packaging: Recycled plastics are used for packaging medical supplies and pharmaceuticals, ensuring safety and compliance with health regulations.

Benefits of Using Recycled Plastics

- Environmental Impact: Reduces the need for virgin plastic production, conserving resources and decreasing greenhouse gas emissions.

- Waste Reduction: Diverts plastic waste from landfills and reduces environmental pollution.

- Cost Savings: Can lower production costs due to the reduced need for raw materials and energy.

- Innovation: Encourages the development of new products and technologies that incorporate recycled materials.