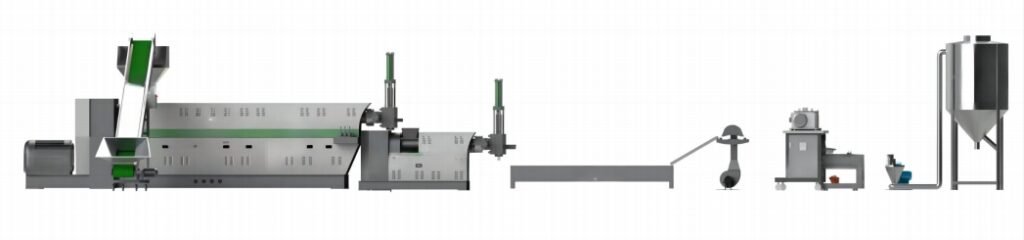

Double Stage Plastic Recycling Machine

JianTai customized plastic recycling machine to meet various needs, with a maximum output of 1000KG/H

Working Principle Of Double Machine Plastic Recycling Machine

- Feeding Stage

- First-Stage Extrusion

- Intermediate Filtration and Conveying

- Second-Stage Extrusion

- Plastic Shaping

- Pelletizing

- Storage and Packaging

Waste Plastic Input: Firstly, waste plastics are conveyed to the first-stage extruder of the equipment via a conveyor belt or other feeding systems. These waste materials can include various types of plastics such as PE (polyethylene), PP (polypropylene), PET (polyethylene terephthalate), etc.

Single-Screw Extruder: The first stage employs a single-screw extruder. Plastics are preheated, melted, and coarsely mixed here. The rotating screw pushes the plastic from the feed inlet to the discharge outlet, during which the plastic is melted through the heating zones. In this process:

- Preheating Zone: The plastic waste gradually heats up and begins to soften.

- Melting Zone: The plastic completely melts under the action of heating elements.

- Coarse Mixing Zone: The screw’s shear action makes the plastic mix uniformly, primarily as a preliminary treatment for the next step.

- Degassing System: The first-stage extruder typically has a vent to remove volatile substances and bubbles from the plastic. This step improves the quality and purity of the plastic.

Filtration Device: The output plastic from the first stage passes through a filtration device to remove larger impurities and unmelted materials.

Intermediate Conveyance: The filtered molten plastic is conveyed to the second-stage extruder via pipes or other conveying systems.

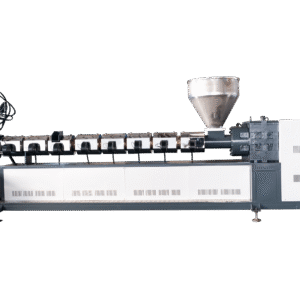

Twin-Screw Extruder: The second stage uses a twin-screw extruder for further mixing and extrusion. The twin-screw system provides stronger mixing capability and shear force, better handling impurities in the plastic and ensuring uniformity and consistency of the plastic.

- Enhanced Mixing: The intersecting rotation of the two screws applies higher shear force to the plastic, making it mix more evenly.

- Homogenization: Ensures consistent temperature and viscosity of the plastic melt to form stable quality pellets.

- Plasticization and Stabilization: After being processed by the twin-screw, the plastic melt achieves better plasticization and stability.

Die Head: The plastic melt is pushed from the twin-screw extruder into a die head, forming long plastic strands through the die. The design of the die determines the shape and size of the final plastic pellets.

Water Cooling: The extruded plastic strands are guided into a cooling water tank for rapid cooling to solidify them. Water cooling helps the plastic strands maintain shape and harden into solid materials.

Pelletizer: The cooled plastic strands are fed into a pelletizer, which cuts them into uniform pellets. The blades of the pelletizer cut the plastic strands into specified sizes of plastic pellets, which are the final product of the recycled plastic.

Drying System: The pellets are further dried by a centrifugal dryer or airflow dryer to remove surface moisture.

Storage Silos: The dried plastic pellets are conveyed to storage silos, awaiting packaging or further processing.

Packaging: Pellets are packaged into bags or boxes as needed for transportation and sale.

Yuyao Jiantai Plastic Machinery Co., Ltd.

JianTai Co., Ltd, established in 2005, is a professional manufacturer of high-tech, industrial plastic recycling machines. First, we offer recycling equipment for large-scale recycling. Next, our machines handle large volumes of post-consumer, post-commercial, and post-industrial plastic waste streams. Because of our expertise, we provide effective solutions for plastic recycling.

Our in-house R&D team of engineers and technicians has spent countless hours developing innovative machines with efficiency, usability, durability, and safety in mind. First of all, you can rest assured that our equipment uses only the highest quality materials and parts. If well maintained, these machines will operate year after year. Because of our endless strive for perfection, precision, and customer satisfaction, JianTai Recycling Machinery has won world recognition as one of the leading manufacturers of recycling machinery.

For plastic recycling plants looking for turnkey solutions, we offer the complete design and installation of recycling lines. For example, we have PET bottle washing lines, PE film washing lines, and even entire municipal waste processing plants (Materials Recovery Facility, MRF). With more than three decades in the plastic recycling industry, we have a lot of experience. Because of this, we’re confident we can quickly and efficiently help bring your plastic recycling plant to new heights.