Small Single Screw Plastic Recycling Machine

The Small Single Screw Plastic Recycler is perfect for efficient recycling. With a capacity of 80KG/H to 1000KG/H and a complete set of basic equipment, it is an environmentally friendly, cost-effective solution for processing plastic waste.

Brand Trust

Our in-house R&D team of engineers and technicians has spent countless hours developing innovative machines with efficiency, usability, durability, and safety in mind. First of all, you can rest assured that our equipment uses only the highest quality materials and parts. If well maintained, these machines will operate year after year. Because of our endless strive for perfection, precision, and customer satisfaction, JianTai Recycling Machinery has won world recognition as one of the leading manufacturers of recycling machinery.

Brand Experience

For plastic recycling plants looking for turnkey solutions, we offer the complete design and installation of recycling lines. For example, we have PET bottle washing lines, PE film washing lines, and even entire municipal waste processing plants (Materials Recovery Facility, MRF). With more than three decades in the plastic recycling industry, we have a lot of experience. Because of this, we’re confident we can quickly and efficiently help bring your plastic recycling plant to new heights.

ote:This price does not include transportation costs, etc. and is only a reference price for the complete set.

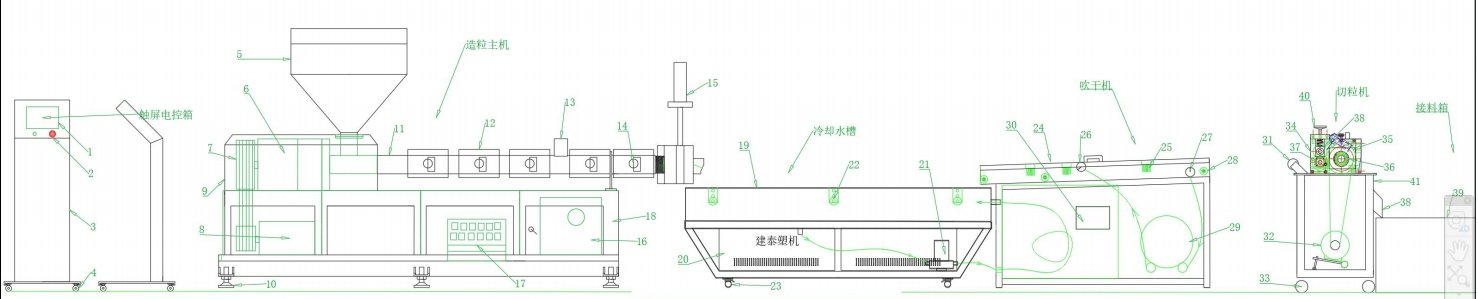

| Number | Part Name | Number | Part Name |

|---|---|---|---|

| 1 | Main Screen Control Cabinet | 21 | Water Pipe Connection Inlet |

| 2 | Screen Power | 22 | Water Tank Drain Valve |

| 3 | Screen Switch | 23 | Cooling Water Tank Drain Valve |

| 4 | Screen Emergency Stop | 24 | Water Tank |

| 5 | Hopper | 25 | Water Tank Stand |

| 6 | Extruder Screw | 26 | Filter Rack |

| 7 | Gearbox | 27 | Filter Screen |

| 8 | Motor | 28 | Water Tank Drainage Outlet |

| 9 | Inverter | 29 | Filter Mesh |

| 10 | Extruder Electrical Control Cabinet | 30 | Drying Blower |

| 11 | Stainless Steel Heating Band | 31 | Pelletizer |

| 12 | Fan | 32 | Pelletizer Blade |

| 13 | Hydraulic Non-stop Single Die-head | 33 | Pelletizer Feed Inlet |

| 14 | Hydraulic Pump | 34 | Pelletizer Heating Band |

| 15 | Cooling Water Tank | 35 | Pelletizer Fan |

| 16 | PLC Control Cabinet | 36 | Pelletizer Motor |

| 17 | Stainless Steel Water Tank | 37 | Pelletizer Emergency Stop |

| 18 | Air Drying Device | 38 | Pelletizer Electrical Control Cabinet |

| 19 | Pelletizer | 39 | Pelletizer Power Supply |

| 20 | Pelletizer Control Cabinet | 40 | Pelletizer Switch |

| 41 | Pelletizer Drain Valve |